Faster to higher quality:

Safe and comfortable travel in a train is only possible on tracks lying in the correct geometrical position. The first machines that made it possible to produce this state of the track quickly and reliably were built by Plasser & Theurer. The hydraulic non-synchronous constant pressure tamping principle – which is still the method most widely used today – was developed by Plasser & Theurer to hold the tracks in the correct position.

Meanwhile, thousands of levelling, lifting, lining and tamping machines made in Linz are operating all over the world. Today, this range of machines offers a unique selection to meet the individual requirements of the operators. The main categories are tamping machines in standard railway vehicle design for tracks and turnouts which are equipped with one, two, three or four-sleeper tamping units; then there are self-loading and road-rail tamping machines and finally lightweight tamping machines. Within these categories there are machines built as special models for example with full sound insulation or for special tasks such as tamping Y-type sleepers, for spot fault elimination, for tamping tracks with sharp curves, tight clearance gauges or live rails as well as machines for different track gauges and clearance gauges.

When a train travels over a track, it generates enormous forces. The entire track consisting of rails, sleepers and ballast is an elastic system that deforms and returns to its original position.

Over the long term this high stress results in deterioration of the track geometry. This can lead to anomalies, which means that the ideal geometry of the track is no longer assured and in these areas it becomes necessary to impose temporary speed restrictions.

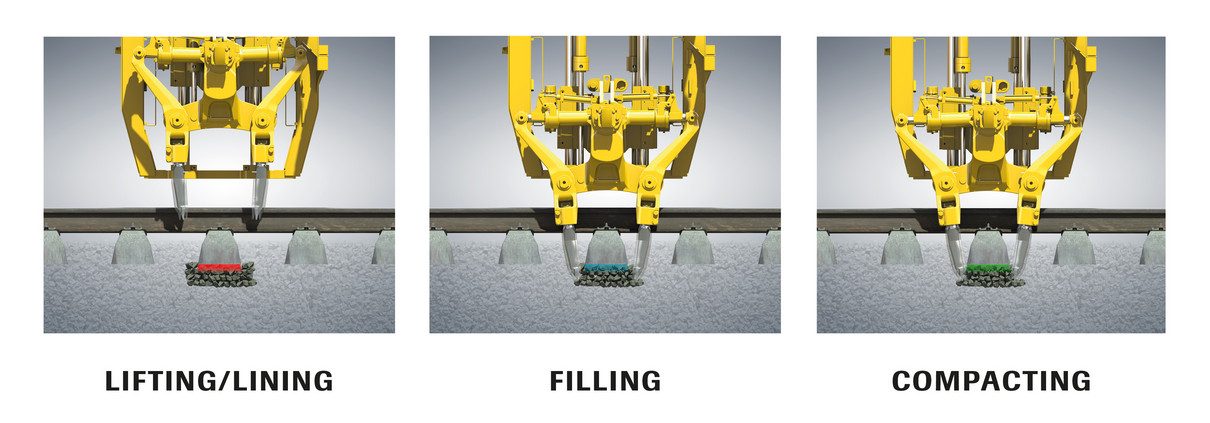

To avoid such a situation, tracks should be maintained at regular intervals – this includes levelling, lifting, lining and tamping. This ensures that the ideal geometry of the track is restored.

Tamping tines pack the ballast under the sleeper to produce a stable sleeper bed.

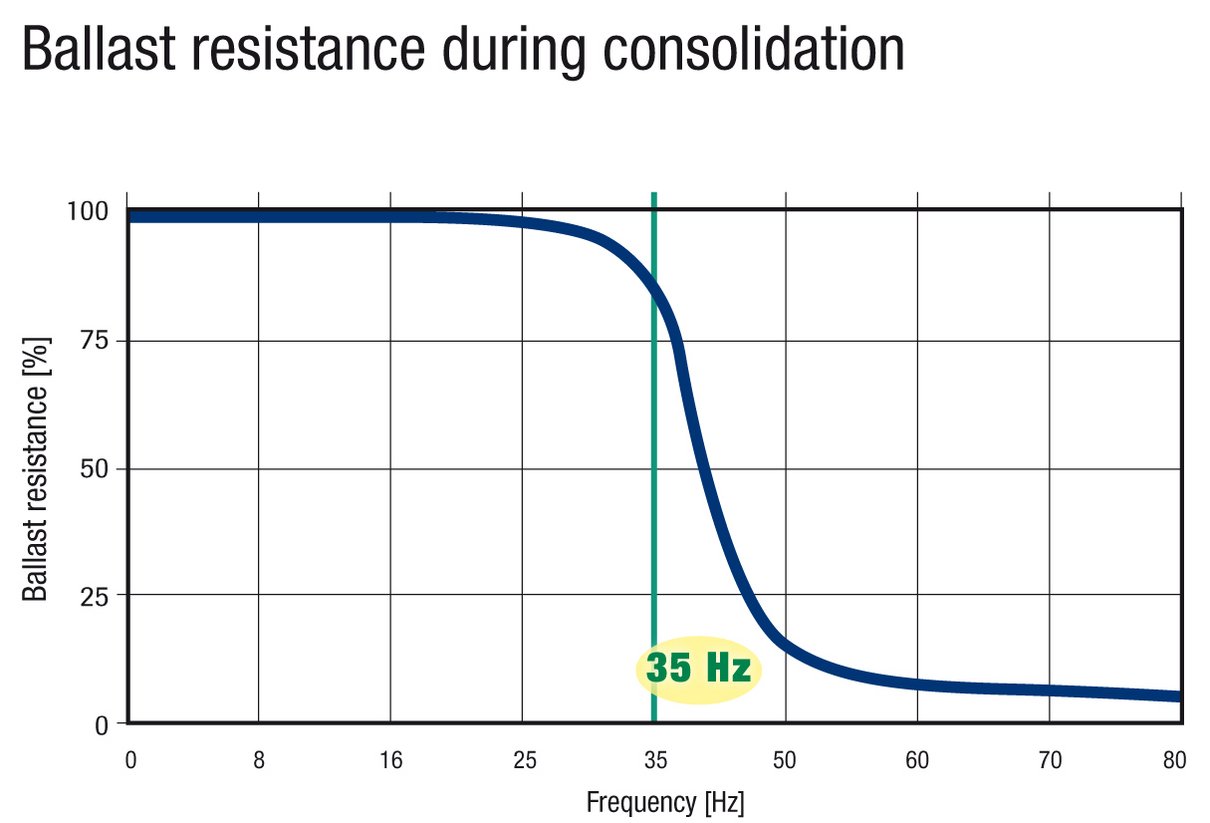

Plasser & Theurer developed a mechanised technique for this purpose: the system of non-synchronous constant pressure tamping which in professional circles is regarded as pioneering and unequalled in quality. The tamping tines penetrate the ballast bed from above and compact the ballast under the sleeper with a squeezing movement. Two factors are decisive here. Firstly, all tamping tines work with the same pressure; and secondly, the tamping tines vibrate with the ideal frequency of exactly 35 Hz. This directional, linear vibration combined with the non-synchronous tine movement produces a homogeneously compacted ballast bed.