Technology

Plasser TampingAssistant

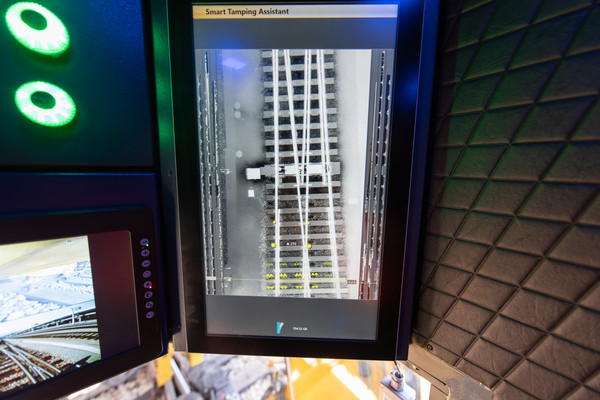

The Plasser TampingAssistant supports operators in tamping complex turnouts which contributes considerably to consistent tamping results. The system supports less experienced operators in tamping turnouts in every area: the result is technologically correct, consistent tamping in compliance with standards and guidelines. Operations on plain-line track sections are also possible.

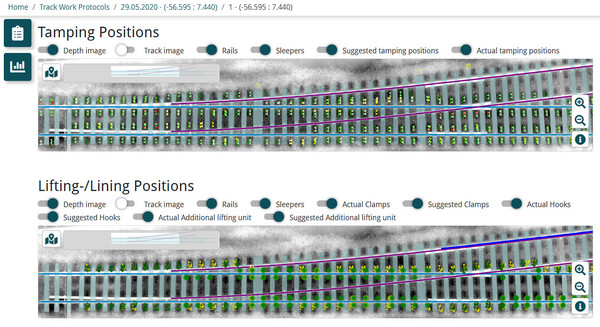

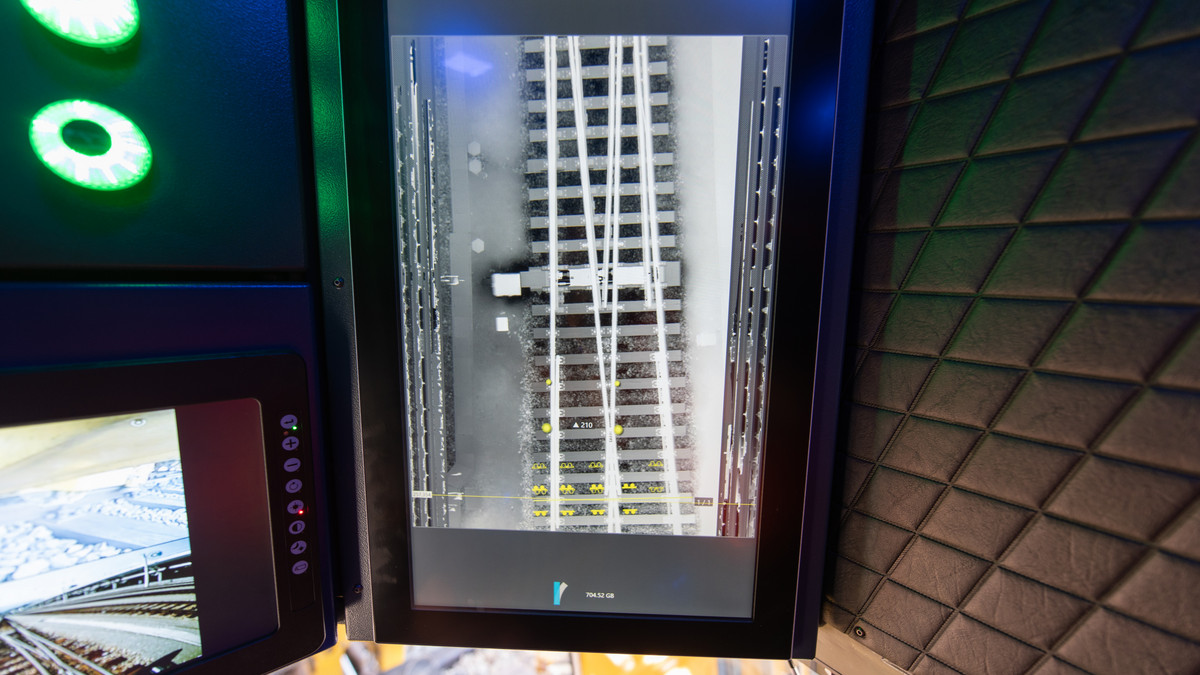

The system is based on artificial intelligence and assists operators by automatically selecting, positioning, and configuring the work units for tamping. The machine stops automatically above the sleeper and positions tamping unit, roller lifting clamps, lifting hooks, and additional lifting unit for turnouts. The configurations for each position are calculated based on the tamping plan and the identified objects. The operator may adjust suggested parameters before manually confirming them.