Highlights

- Increased working output of up to 900 m/h thanks to 2-sleeper tamping

- More space for optional equipment, such as a generator, water tank, or use as a storage area

- The compact design also allows for a flexure curve that protects the rails thanks to the distance of 12 m between bogie pivots

- Two cabs: visibility as per UIC in both directions during transfer travel as well as comfort for operating staff

- Integrate additional maintenance tasks thanks to various trailer options for ploughing, sweeping, stabilizing, transporting, post-measuring, etc.

- More than 100 machines supplied, from narrow gauge to broad gauge

- The global leader in tamping technology – tested under various operating conditions on every continent

Technical data

To view the technical data and download a factsheet on this machine, please enter your contact details.

Gallery

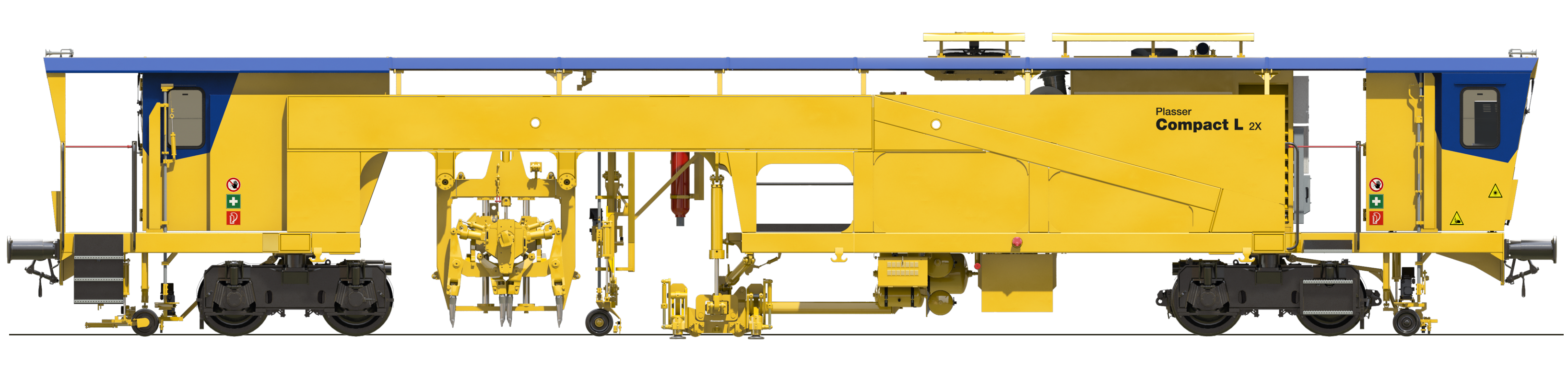

Plasser Compact L 2X

Machine illustration

Plasser Compact L 2X

zoomInzoomOut

Enjoy the benefits of standardization with ModularCustomizing

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.

Illustrations and descriptions may contain optional equipment. We reserve the right to make changes as technology develops.