- Infrastructure

- Conventional lines

- Heavy haul

- High speed

- Field of application

- Plain-line track

- Working mode

- Continuous action

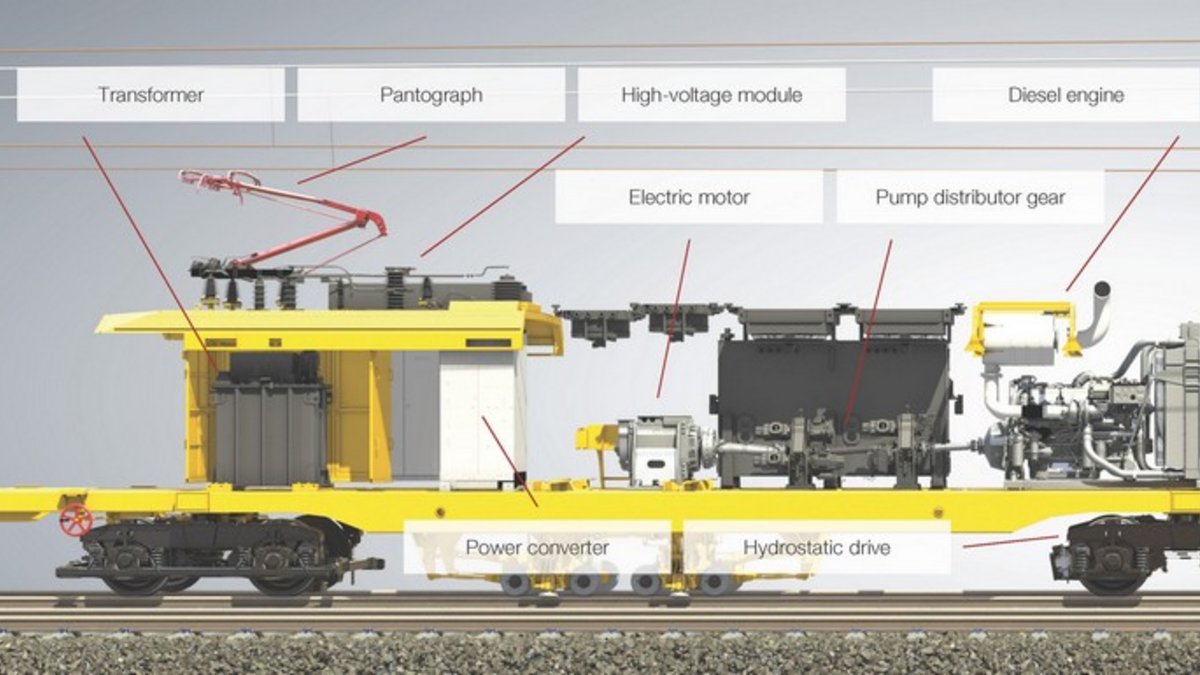

09-4X E³ Dynamic Tamping Express

- New machine design with separate hybrid power wagon

- Powered by a diesel engine or high-performance electric motor: Use of the electrical energy from the contact wire

- Switch between drive systems without interruption Fully automatic control ensures safe changeover

- Electric drive for travelling AND working

- Lower energy and logistics costs: Refuel less often, feed energy back into the grid

- Benefits for the procurement of awards thanks to ecobonus: Extended range of applications in urban areas and tunnels

- Uniform and safe lifting: Lifting and lining unit with four roller lifting clamps

- Maximum maintenance sustainability: More stable track position due to simultaneous tamping of four sleepers

- Integrated dynamic track stabilization: Control initial settlement of the track bed after tamping

- New design in all cabs: Improved ergonomic design developed together with the operators

- Simple and clearly laid-out operating concept: Plasser IntelligentControl

- Complete control of the measuring systems: Front cab with WIN-ALC automatic guiding computer

- Measure, document, and analyse the track geometry while working: DRP Data Recording Processor

- Reduced noise emission thanks to extensive noise protection measures (Sound-insulated work units, improved sound insulation of the engine compartment)

Features

Quality cuts costs: our machines turn a tidy profit

To date, Plasser & Theurer has supplied 17,800 machines. Most of them are still in operation. This attests to the quality of the machines and the value of our Customer Services’ life-long machine and fleet support. Plus, it proves that high quality ensures high cost-efficiency: machines that have been in operation for 20 or 30 years paid off years ago.

Economic – Ecologic – Ergonomic

The latest track maintenance machines use both the electrical energy from the contact wire and batteries to power the working drive. Our new E³ drive technologies reduce local emissions - of both pollutants and noise – to a minimum on the work site. Introduced in 2015, Plasser & Theurer’s E³ machines stand for: Economic – Ecologic – Ergonomic.

Illustrations and descriptions may contain optional equipment. We reserve the right to make changes as technology develops.