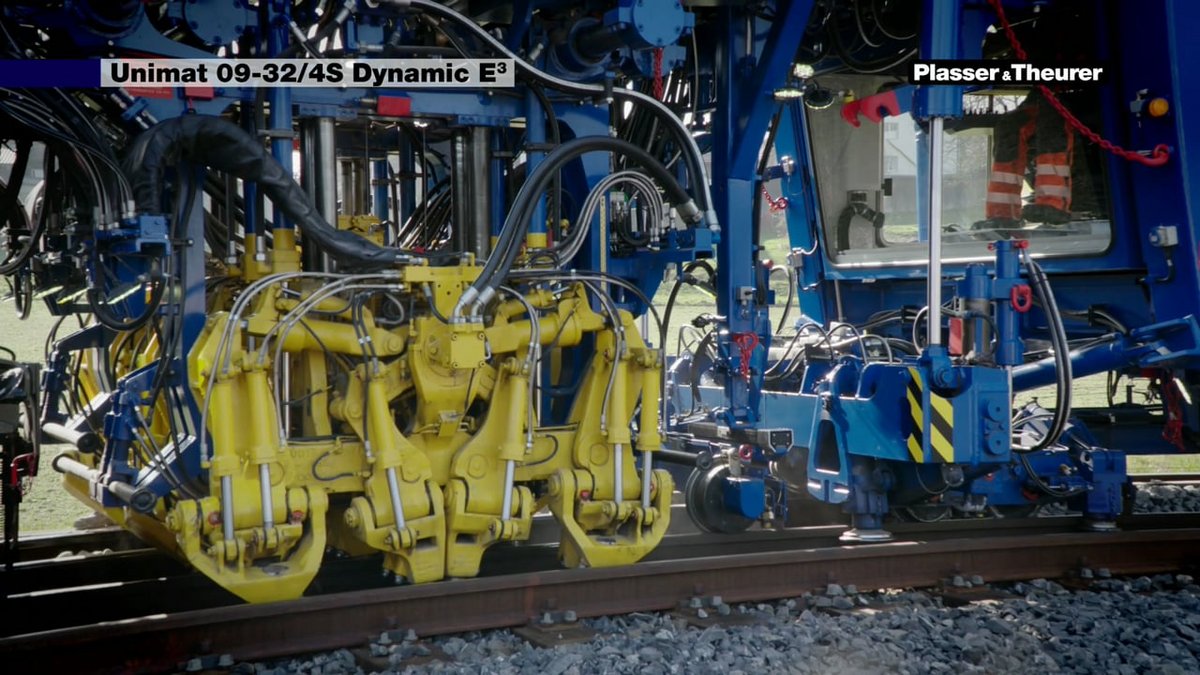

Continuous-action 2-sleeper tamping, stabilizing, and profiling

- Infrastructure

- Conventional lines

- Heavy haul

- High speed

- Field of application

- Turnout

- Plain-line track

- Working mode

- Continuous action

For the first time, our E³ hybrid drive system powers a continuous action turnout tamping machine. Krebs Gleisbau AG and Swiss Railways have already set store by the new machine.

The new E³ hybrid drive concept allows the machine to be powered either via a diesel engine or via an electric motor using the electrical energy of the contact wire. Both engines generate the hydraulic pressure required for all systems, from the hydrostatic drive for running mode and working drive mode to the work units. The first two machines fitted with the E³ hybrid drive system – a 09-4X E³ Dynamic Tamping Express and a BDS 2000 E³ – have stood the test of time in regular worksite operation in Austria.

Features

Quality cuts costs: our machines turn a tidy profit

To date, Plasser & Theurer has supplied 17,800 machines. Most of them are still in operation. This attests to the quality of the machines and the value of our Customer Services’ life-long machine and fleet support. Plus, it proves that high quality ensures high cost-efficiency: machines that have been in operation for 20 or 30 years paid off years ago.

Economic – Ecologic – Ergonomic

The latest track maintenance machines use both the electrical energy from the contact wire and batteries to power the working drive. Our new E³ drive technologies reduce local emissions - of both pollutants and noise – to a minimum on the work site. Introduced in 2015, Plasser & Theurer’s E³ machines stand for: Economic – Ecologic – Ergonomic.

Illustrations and descriptions may contain optional equipment. We reserve the right to make changes as technology develops.