- Infrastructure

- Conventional lines

- High speed

- Field of application

- Turnout

- Track

- Working mode

- Continuous action

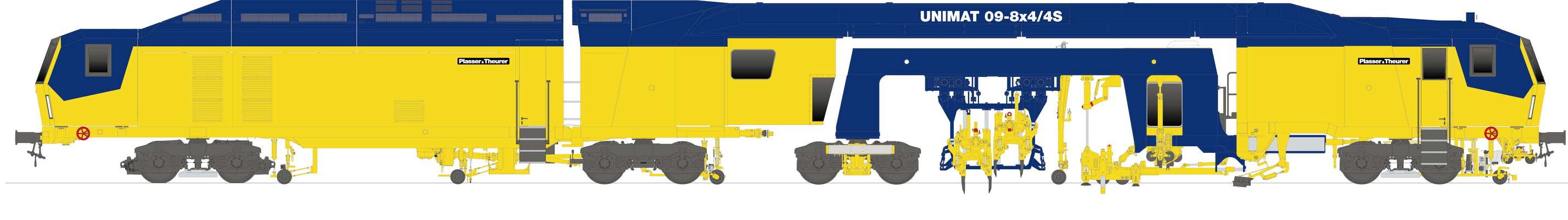

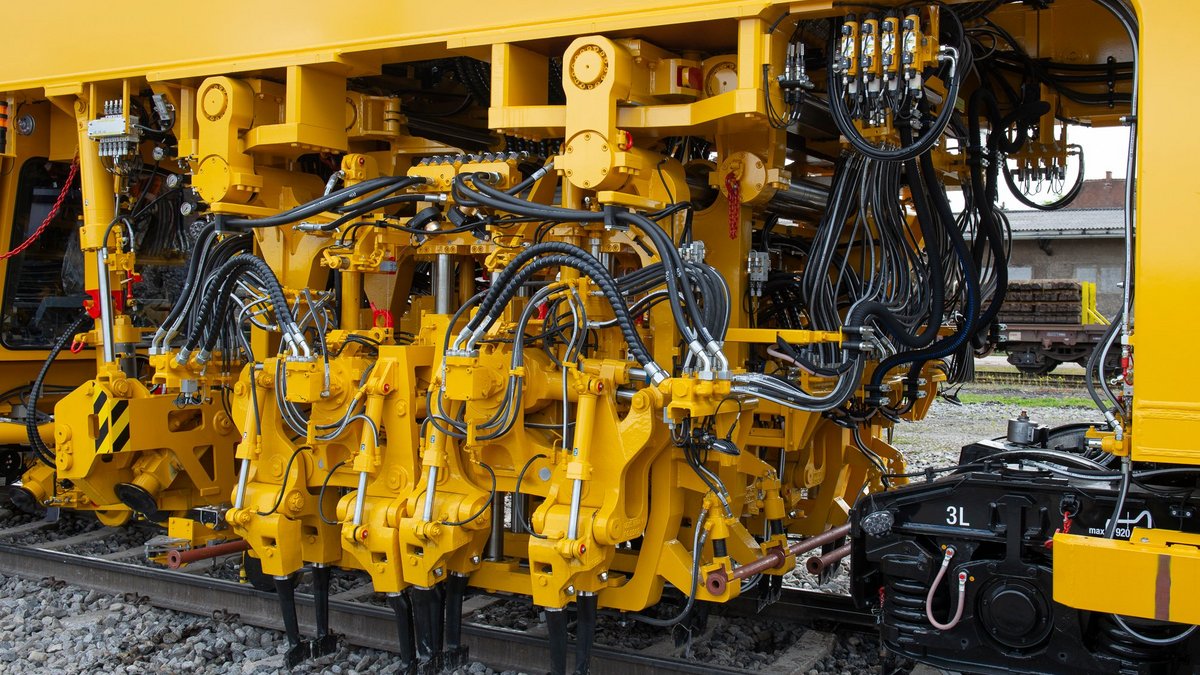

- Maximum flexibility thanks to the pivoting tamping unit, eight tamping unit segments that can be lowered individually, and tilting tamping tines

- Increased output thanks to continuous working action and 2-sleeper tamping technology

- React to obstacles flexibly by switching to 1-sleeper tamping mode

- Designed to treat the heaviest types of superstructure (heavy-haul lines)

- Reaches the worksite fast thanks to a maximum speed of 100 km/h during self-propelled transfer travel

- Spacious multi-purpose areas (e.g. workshop, crew area)

- Fast approval at reduced cost thanks to the use of standardized machine components and systems

The measuring system for documenting track geometry

The digital recording processor (DRP) records, evaluates, and displays various track parameters, such as the longitudinal level, alignment, crosslevel, and twist. The real-time display on the panel PC enables immediate analysis of the individual channels and makes it possible to describe individual events using the comment function.

more about Plasser & Theurer tamping technologyFeatures

Enjoy the benefits of standardization with ModularCustomizing

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.