Technology

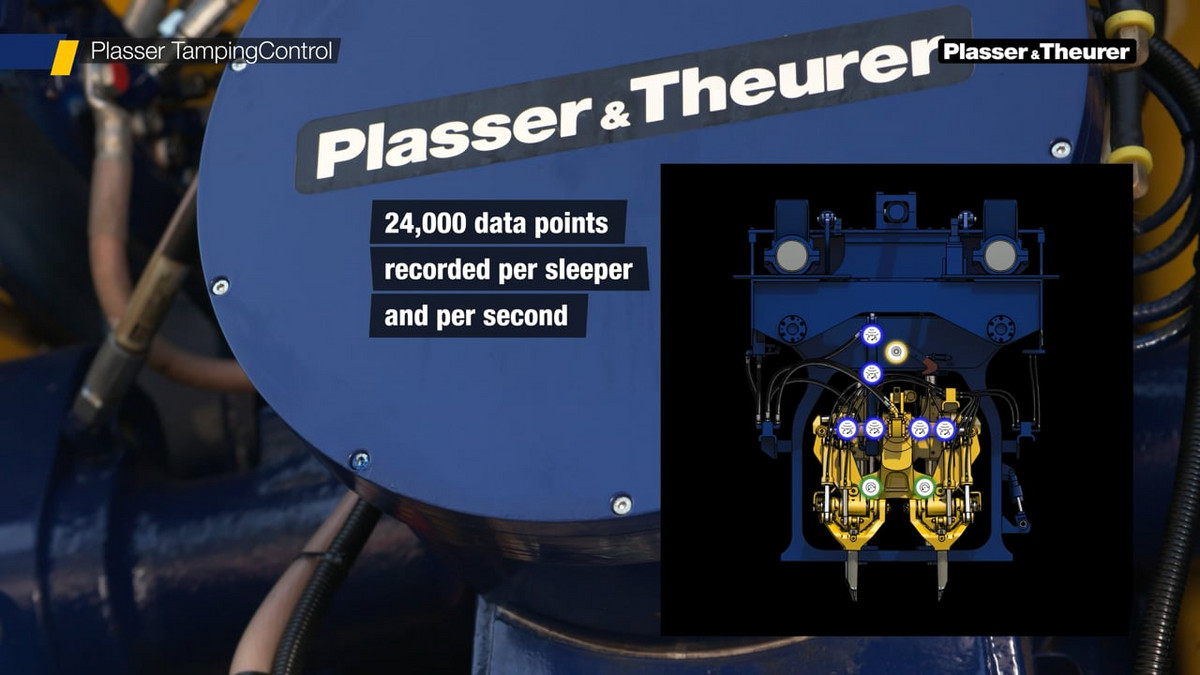

Plasser TampingControl

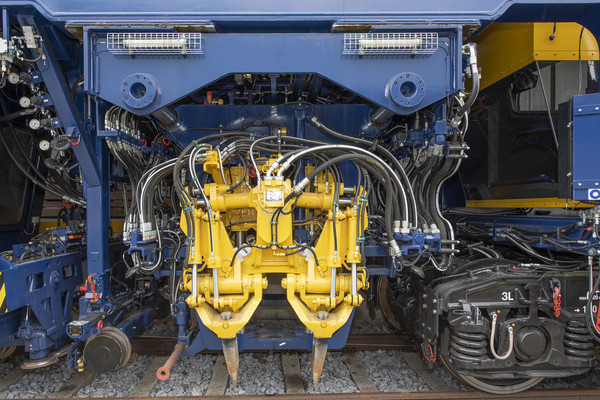

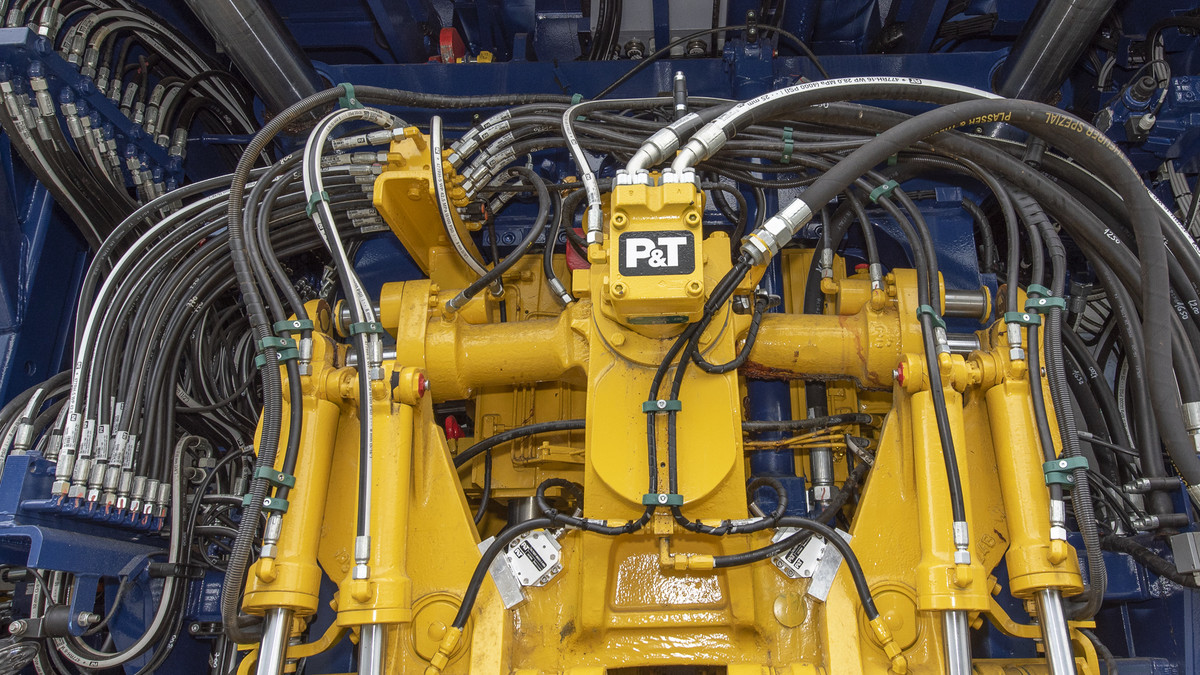

The aim of every tamping process is optimum filling and compaction below the sleeper, which forms the basis of a precise, long-lasting track geometry. Sufficiently filled sleepers ensure optimum load transfer that withstands planned traffic loads.

Sensors are used to record the tamping unit's measuring values and analyse them in real time. Calculations of ballast and work quality are based on this data, allowing the operator to optimize working parameters for filling and compaction as needed. The result is a sturdy sleeper bed and more resilient track geometry.