- Infrastructure

- Conventional lines

- Heavy haul

- Field of application

- Turnout

- Track

- Working mode

- Spot maintenance

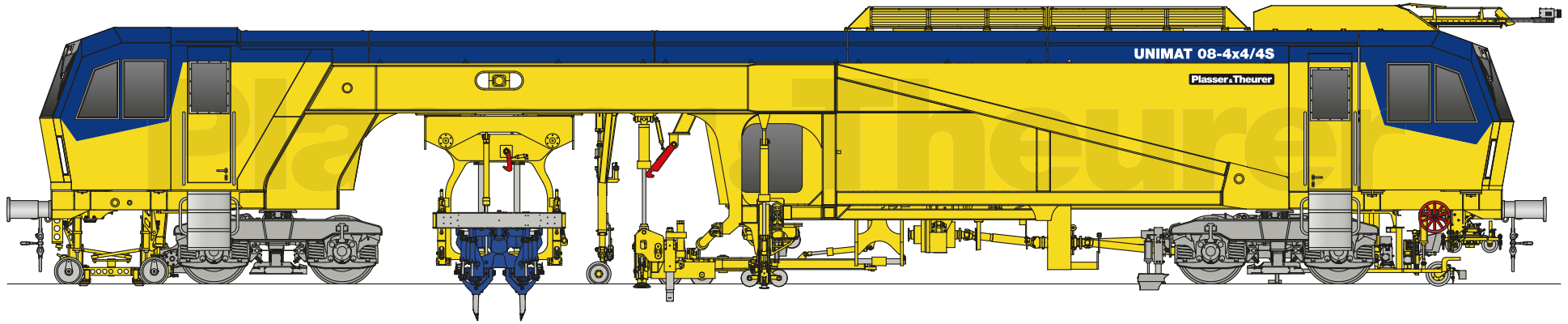

Unimat 08-4x4/4S

- Industrial design adds value: a new level of ergonomic operation

- 4x4 tamping technology for 4-rail tamping

- Rotation speed modulation of the vibration reduces noise and wear

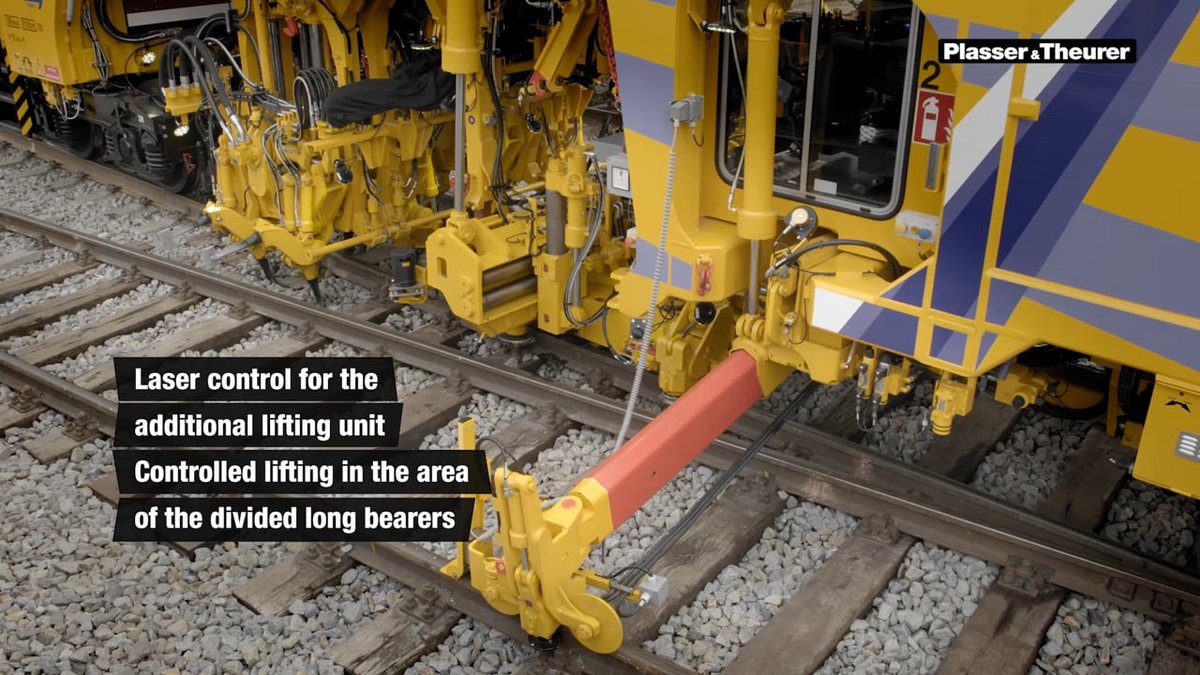

- Uniform distribution of lifting forces thanks to 3-rail lifting

- PlasserSmartTamping – The Assistant: automatic turnout tamping

- SmartALC: reliable correction of the track geometry

- Documenting during work: control measuring without trailer

- Trailer for additional functions: Customised equipment

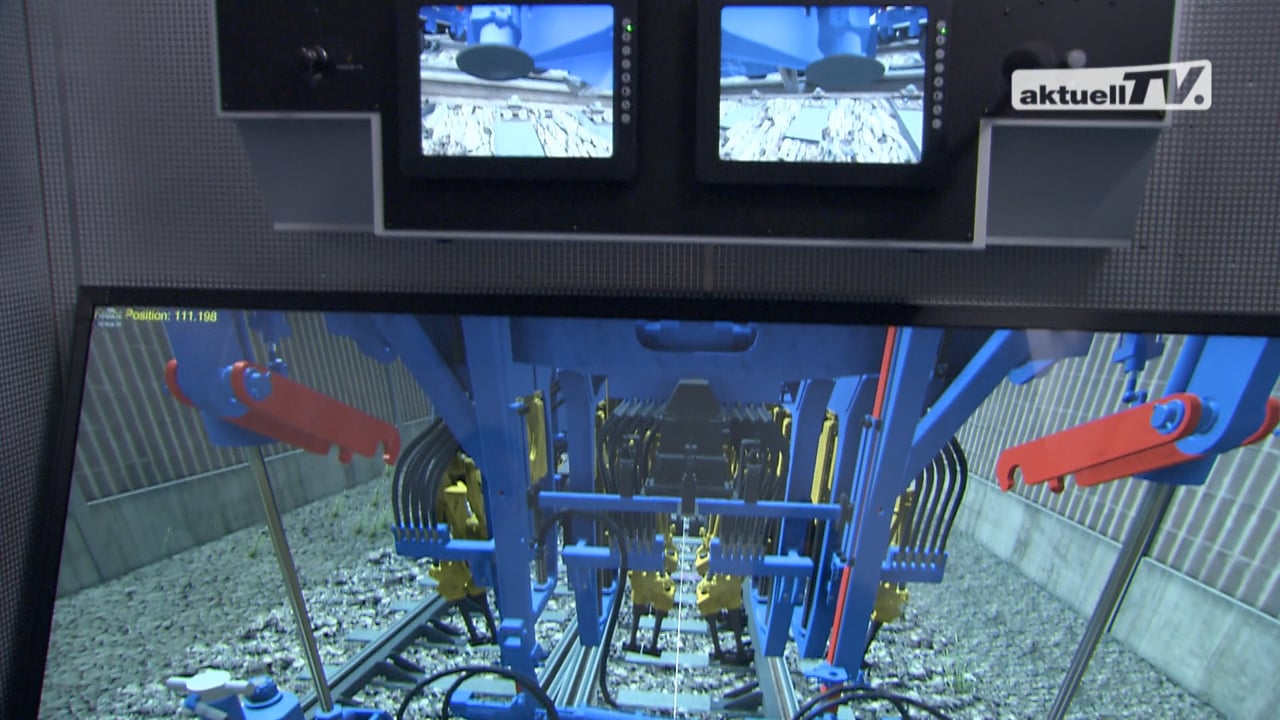

The tamping simulator – High level of expertise within a short time

Practical training in a new dimension – the 09-3D tamping simulator

Our tamping simulators demonstrate the convincing advantages of modern simulation technology.

Features

Enjoy the benefits of standardization with ModularCustomizing

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.