Machine data treasure hunt

The aim of predictive maintenance strategies is to estimate the optimum time for maintenance measures. With special machine construction, characterized by small production quantities, conventional statistical or AI-supported data analyses quickly reach their limits. What is needed is a concept that derives specific recommendations for action from the wealth of machine data.

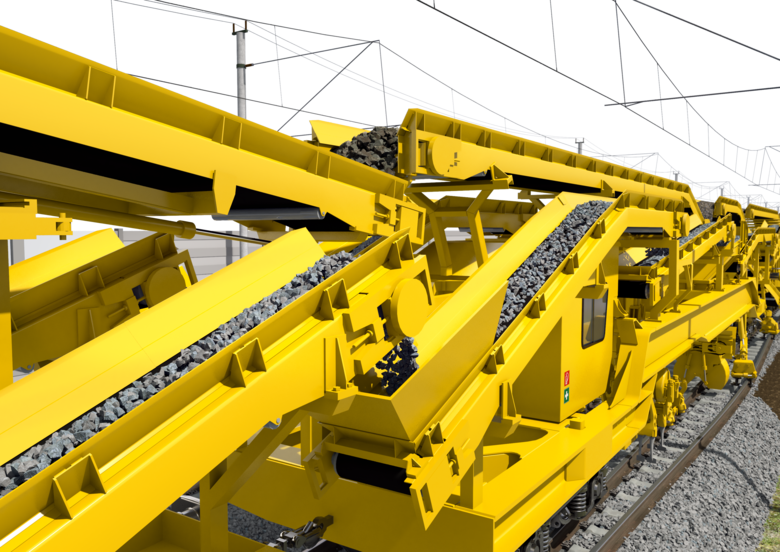

Machine