- Infrastructure

- Conventional lines

- Heavy haul

- High speed

- Industrial railways

- Field of application

- Track

- Working mode

- Continuous action

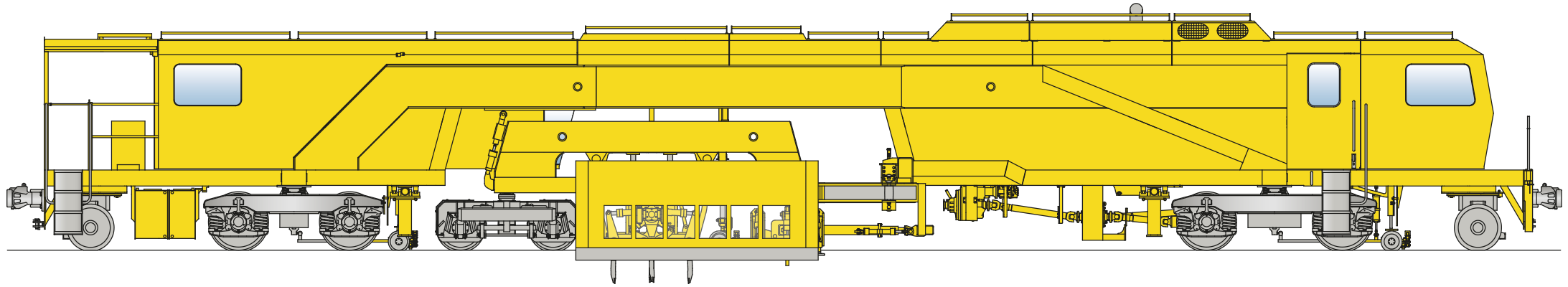

09-2X

The required tamping performance per time unit determines the size of the tamping unit. In that sense, a high annual output may be just as crucial as short track possessions on high-capacity lines. The 09-2X and 09-3X models are equipped with the same frame design, and the 09-2X employs 2-sleeper working technology. This 2-sleeper technology provides optimal conditions assuming tamping at maximum speed is less of a priority. Our 09-2X model, with its compact 2-sleeper tamping unit, will win you over: more than 1,200 machines currently in operation attest to its success. You have the choice of either a classic 2-sleeper tamping machine or a machine which can switch to tamping individual sleepers using 1X mode (09-2X/SD).

Quality of tamping tines

Our high-quality tamping tines allow higher kilometre outputs and have to be replaced less often. In both cases, our original tamping tines have set the standard. Their design is crucial: they are produced as monobloc components forged in one piece and coated with a tungsten-carbide armour for all surfaces that come into contact with the ballast.

more about Plasser & Theurer tamping technologyFeatures

Enjoy the benefits of standardization with ModularCustomizing

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.