- Infrastructure

- Urban transport

- Industrial railways

- Field of application

- Turnout

- Track

- Working mode

- Cyclic action

- Spot maintenance

- Variable maintenance of plain line tracks and turnouts

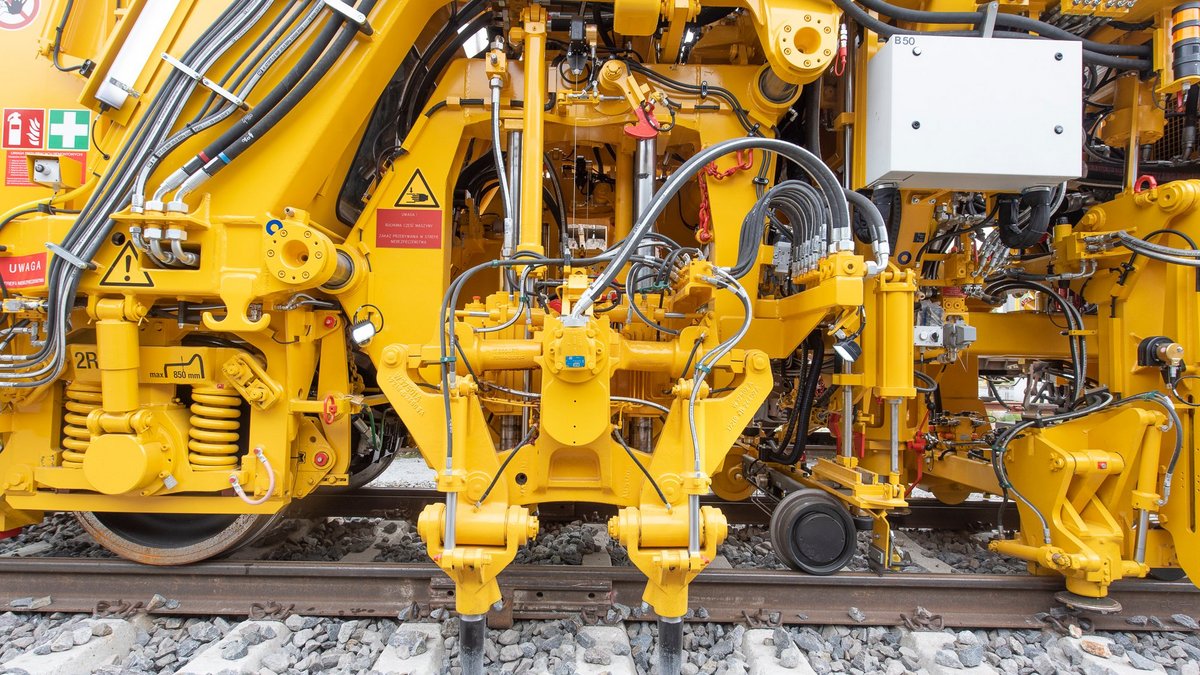

- Time-saving turnout tamping thanks to individually lowerable tamping unit segments

- All tines are in tilting design

- The world's leading tamping technology - tested under various operating conditions on every continent

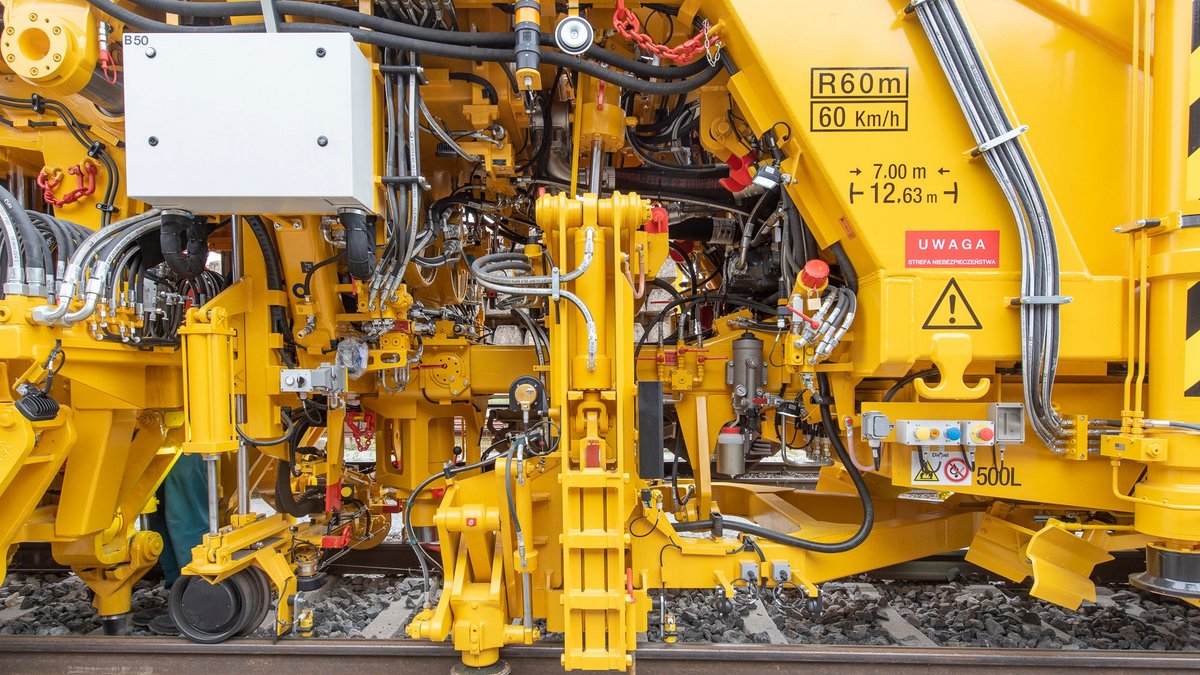

- lntegrated lifting jacks ensure the machine can be seif-loaded onto flat-bed trailers to transport it on roads

- Greatest flexibility, particularly for networks without siding tracks

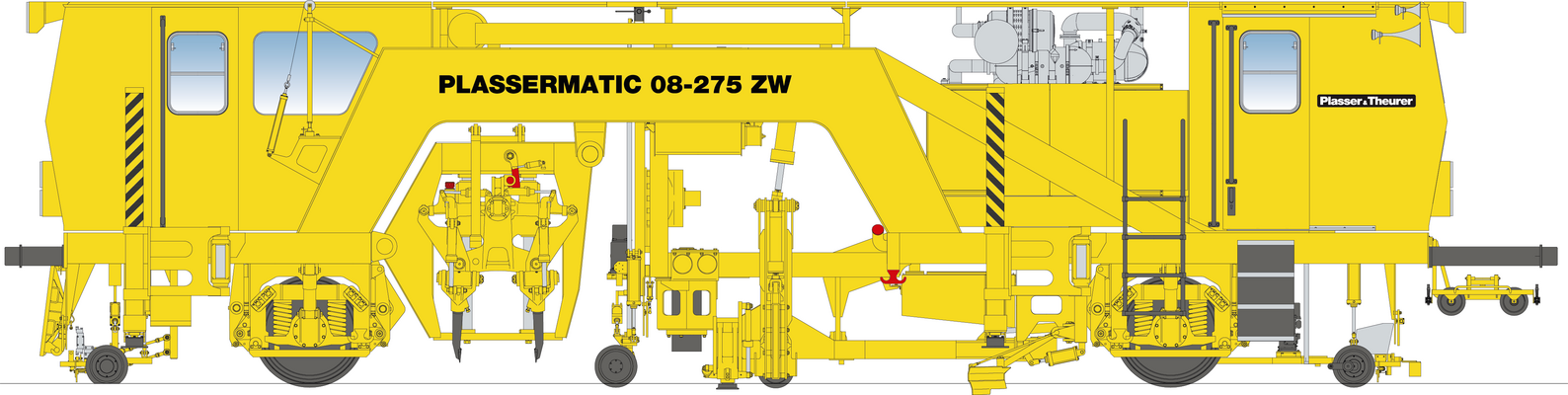

iaf 2022 - the 17,000th machine

The 17,000th machine built by Plasser & Theurer in the company's almost 70-year history was handed over to a customer from the iaf partner country Poland. More than half of all Plasser & Theurer machines are still in operation today. The road/rail Plassermatic 08-275 ZW is a classic for urban networks.

Lifting and lining unit

On the basis of many years of experience, Plasser & Theurer has developed various lifting and lining units which fulfil both requirements and are well suited for specific operating conditions.

ROLLER LIFTING AND LINING UNIT

This work unit is fitted with two lining rollers and two roller lifting clamps per rail, gripping the rail under the rail head. They lift and line in one operation.

COMBINED LIFTING AND LINING UNIT FOR TURNOUTS AND PLAIN TRACK

This work unit has lifting hooks and lining rollers. On request, it is possible to mount additional roller lifting clamps. Lifting and lining is performed in one operation. The lifting hooks can be applied either under the rail head or under the rail base. The entire work unit can also be displaced in longitudinal direction. This ensures that the work unit can be adapted to every situation during turnout maintenance, achieving an optimum lifting and lining process.

more about Plasser & Theurer tamping technologyFeatures

Individual Design for your individualised machine

When it comes to complex high-capacity machines, the requirements of machine operating companies do vary. Country-specific criteria and individual needs are equally important. We satisfy your special requirements with Individual Design machines. This means we design and manufacture machines tailored to you. In particular, your experiences in daily operation shape the final product.