- Infrastructure

- Conventional lines

- Heavy haul

- High speed

- Industrial railways

- Field of application

- Turnout

- Track

- Working mode

- Continuous action

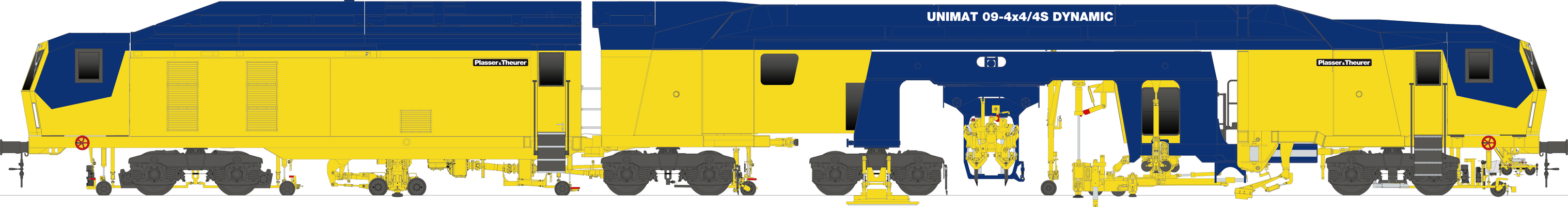

- Variable maintenance of plain line tracks and turnouts

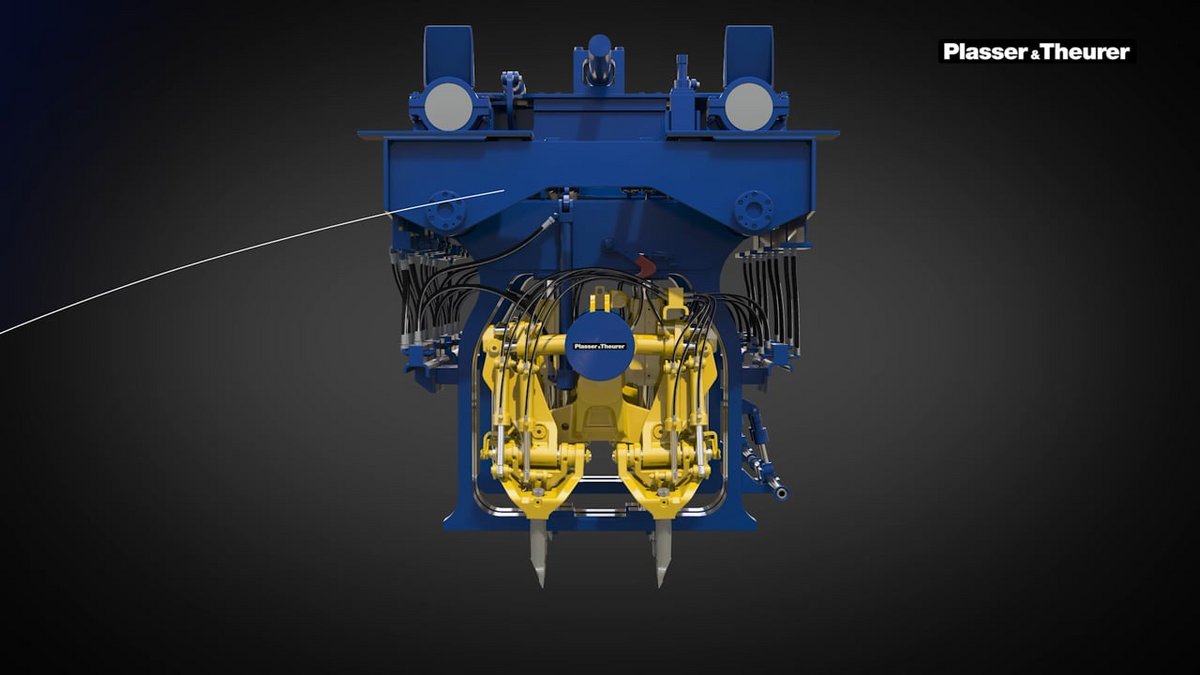

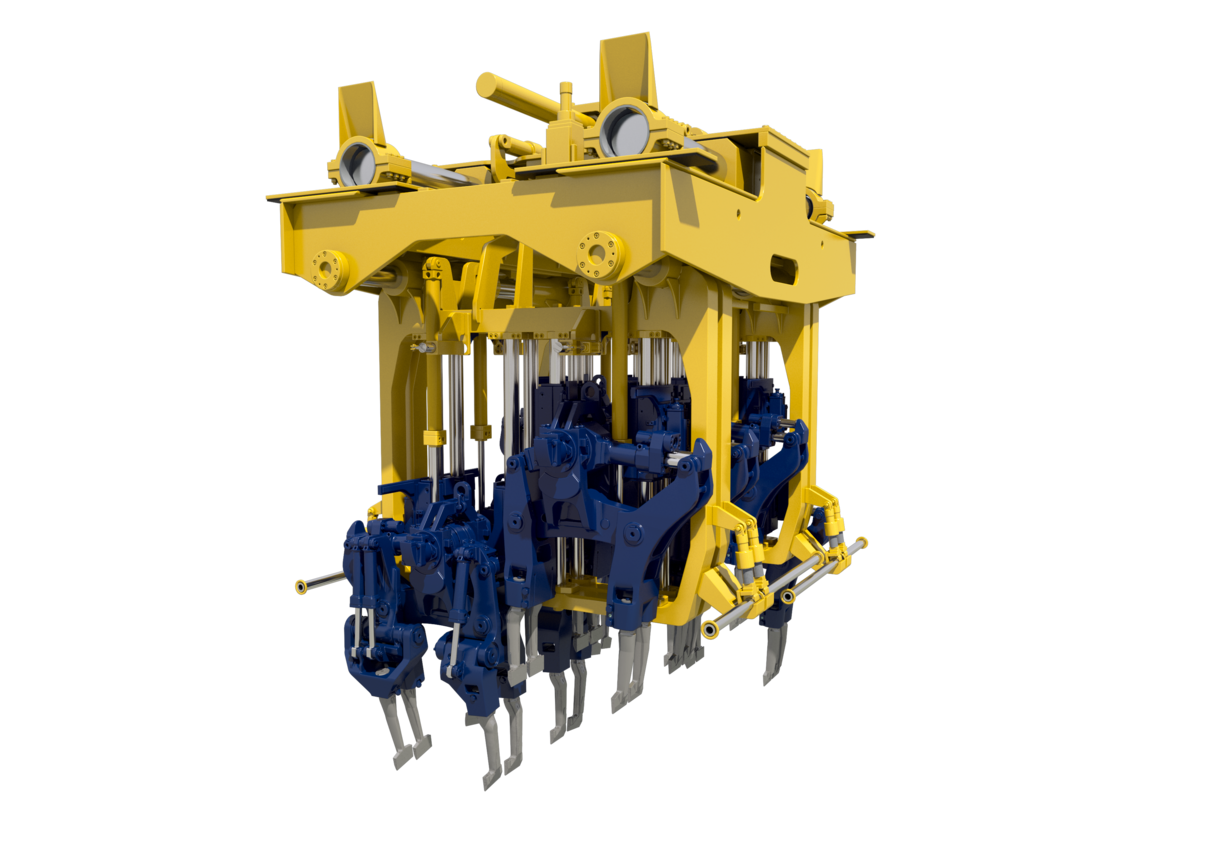

- Maximum flexibility in the turnout thanks to variable use of 16 tamping tines, 3-rail lifting, and 4-rail tamping technology

- The world's leading tamping technology - tested under various operating conditions on every continent

- High track geometry durability and resistance to track buckling thanks to dynamic track stabilisation

- Reduces speed restrictions: optimised availability of the infrastructure following maintenance and dynamic track stabilisation

- The frame is designed to maintain the heaviest types of superstructure (heavy haul lines)

- High availability thanks to a top speed of 100 km/h during running mode under own power

- Approved for line category C2 (axle loads ≤20 t)

In 110 countries

You can choose from a complete range of tamping units for all track and turnout maintenance applications, classified according to output and performance requirements. They are available in various designs and sizes: the perfect fit for all our tamping machines.

more about Plasser & Theurer tamping technologyFeatures

Enjoy the benefits of standardization with ModularCustomizing

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.