- Infrastructure

- Conventional lines

- High speed

- Field of application

- Turnout

- Track

- Working mode

- Continuous action

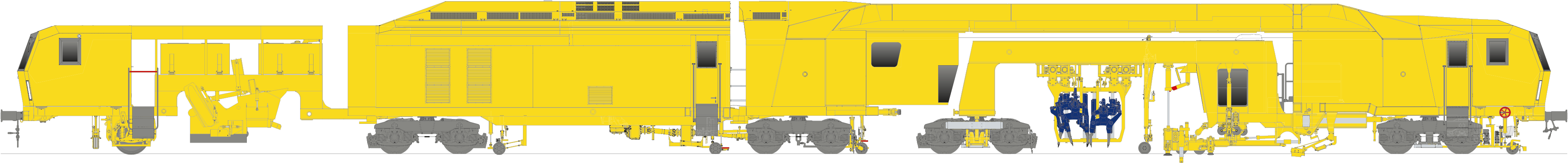

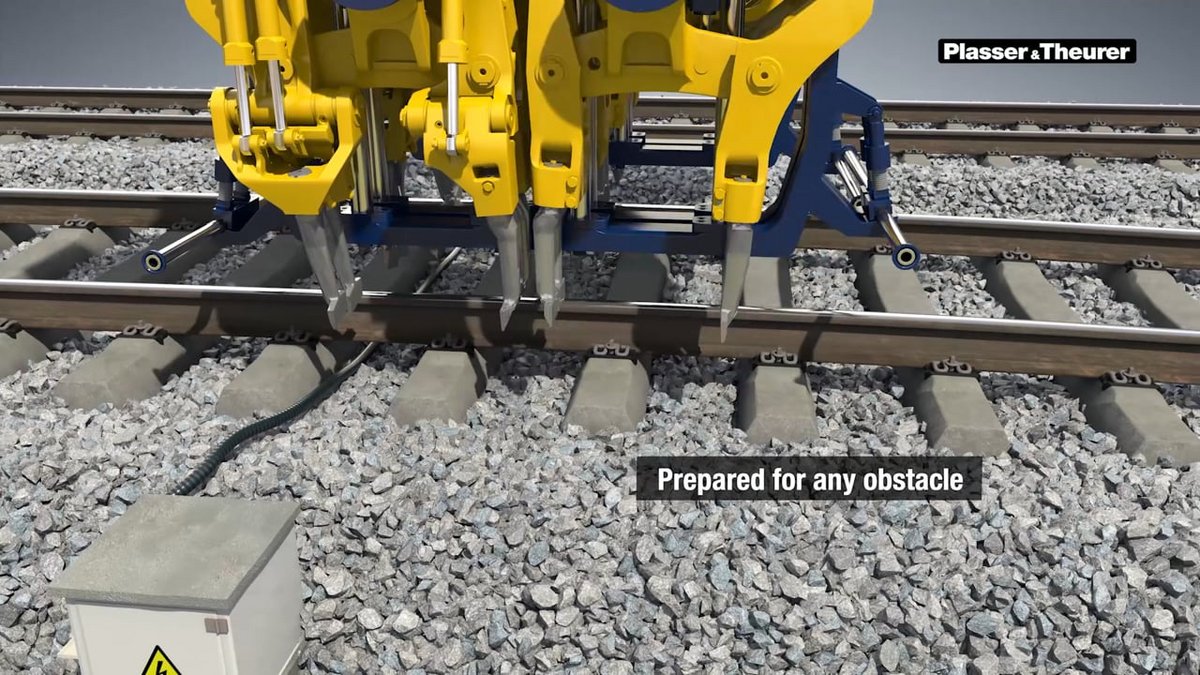

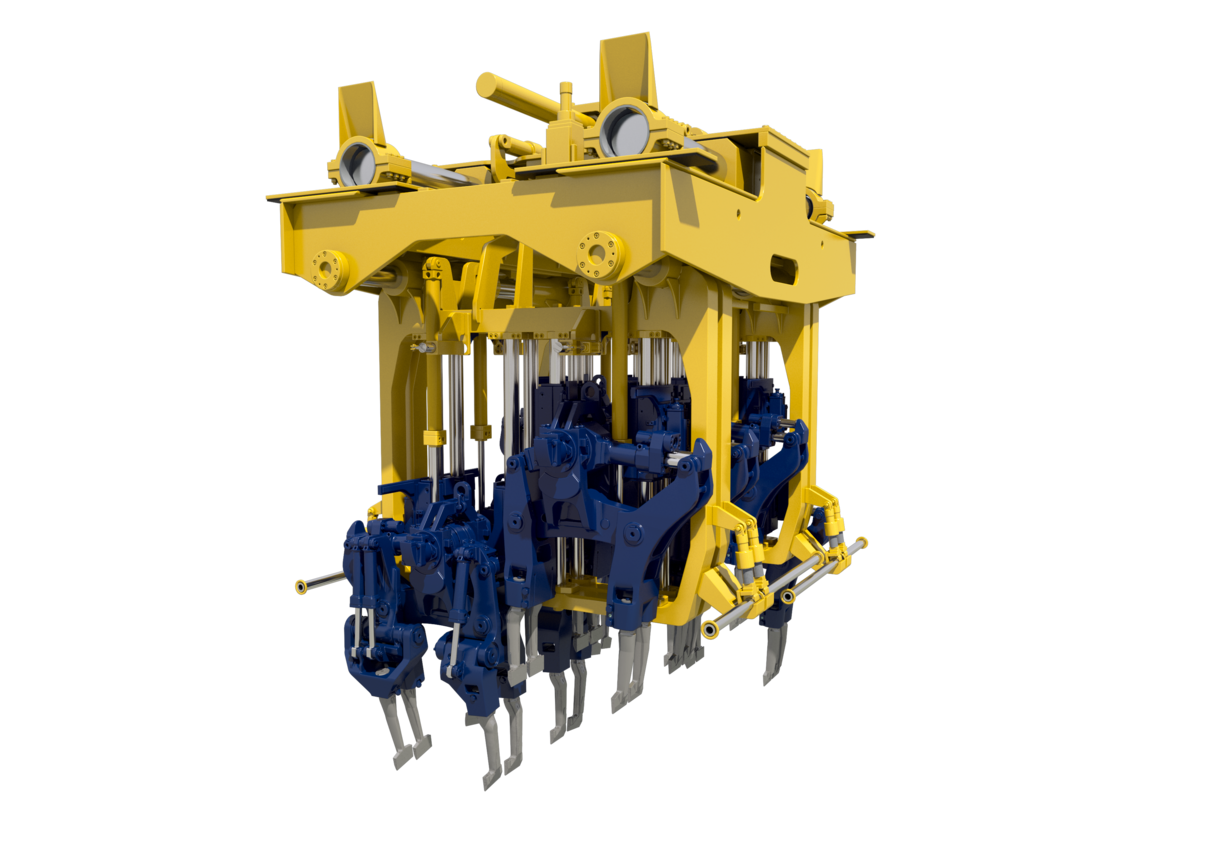

Combining plain track and turnout tamping into a single machine is nothing new. What is new, however, is the 2X-4x4 tamping unit's set-up. The unit combines universal 4x4 turnout tamping in 1-sleeper mode and increased output on the track and parts of the turnout thanks to 2X. It is the perfect unit for maintaining station areas, transfer points, and for tamping several turnouts and short sections of track in between. Thanks to its flexible design, this tamping unit easily handles tamping the other way round: several sections of track and the occasional maintenance of turnouts.

In 110 countries

You can choose from a complete range of tamping units for all track and turnout maintenance applications, classified according to output and performance requirements. They are available in various designs and sizes: the perfect fit for all our tamping machines.

more about Plasser & Theurer tamping technologyFeatures

Enjoy the benefits of standardization with ModularCustomizing

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.