- Infrastructure

- Urban transport

- Industrial railways

- Field of application

- Turnout

- Plain-line track

- Tunnel

- Working mode

- Spot maintenance

Highlights

- Wide range of application thanks to flexible options for transfer by road and rail

- Easy road transport by means of an articulated lorry with a separate three-axle road-based running gear and semi-trailer. No need for loading onto a flat-bed trailer.

- Greatest flexibility, particularly for networks without siding tracks

- The world’s leading tamping technology - tested under various operating conditions on every continent

- Variable maintenance of plain-line tracks and turnouts

- Time-saving turnout tamping thanks to tamping unit segments which can be lowered individually

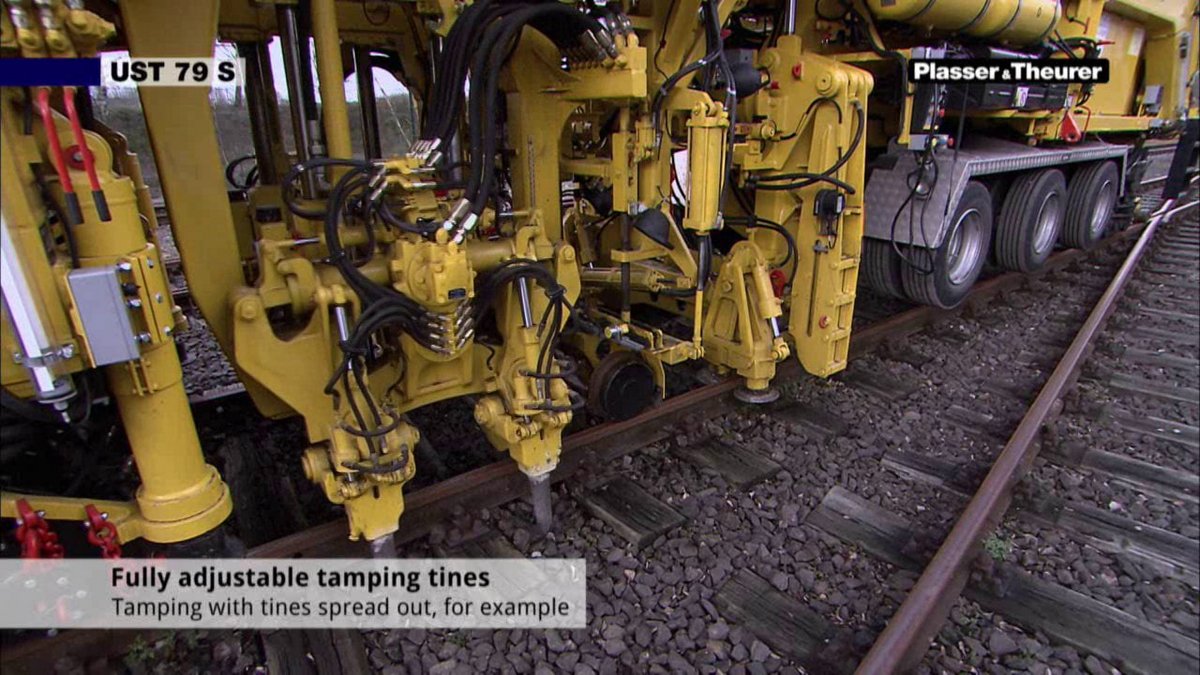

- All tines are in tilting design

Machine illustration

UST 79 S

zoomInzoomOut

Features

Quality cuts costs: our machines turn a tidy profit

To date, Plasser & Theurer has supplied 17,800 machines. Most of them are still in operation. This attests to the quality of the machines and the value of our Customer Services’ life-long machine and fleet support. Plus, it proves that high quality ensures high cost-efficiency: machines that have been in operation for 20 or 30 years paid off years ago.

Illustrations and descriptions may contain optional equipment. We reserve the right to make changes as technology develops.