- Infrastructure

- Réseau conventionnel

- Charges lourdes

- Grande vitesse

- Réseaux ferrés industriels

- Domaine d‘intervention

- Appareil de voie

- Voie courante

- Mode travail

- En continu

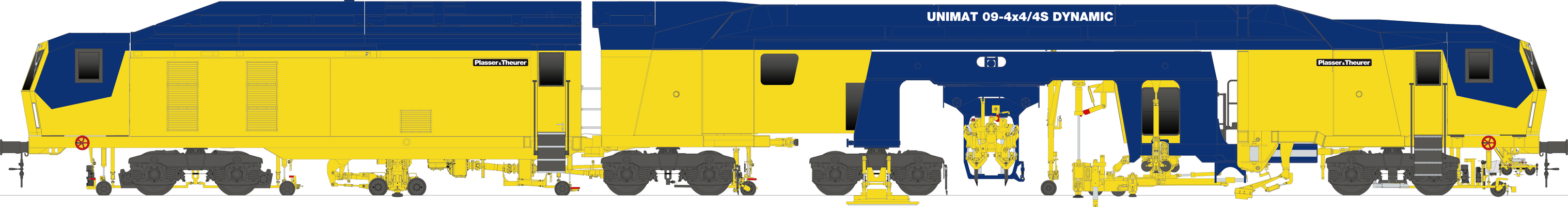

- Variable maintenance of plain line tracks and turnouts

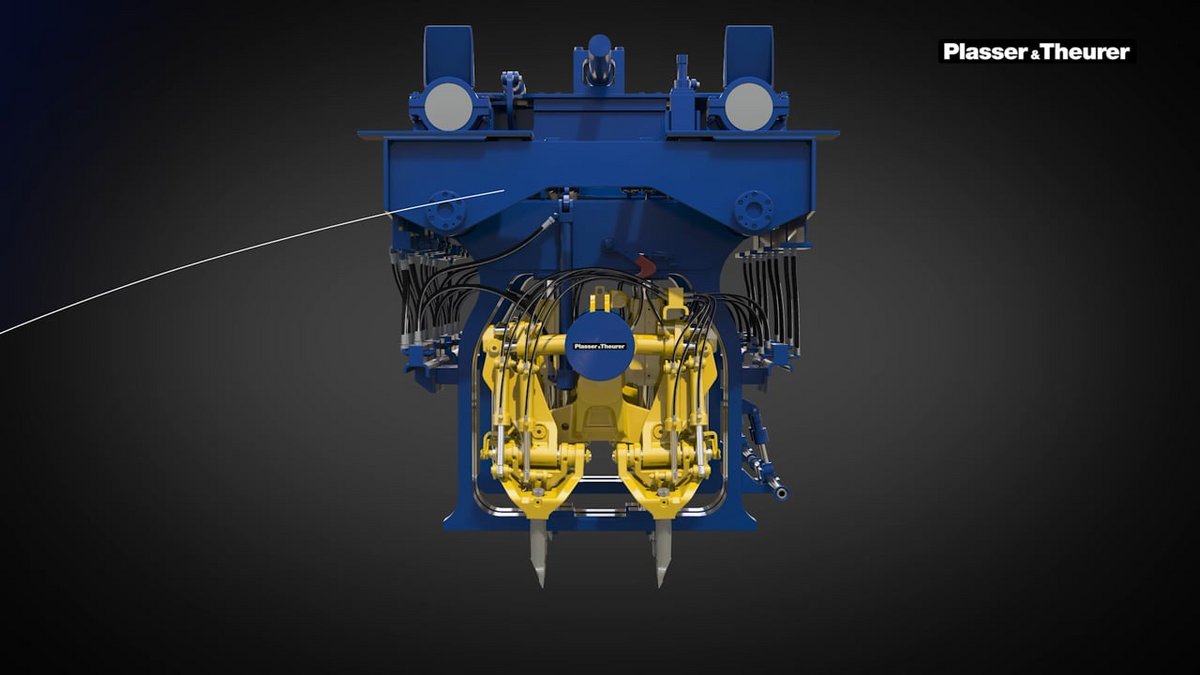

- Maximum flexibility in the turnout thanks to variable use of 16 tamping tines, 3-rail lifting, and 4-rail tamping technology

- The world's leading tamping technology - tested under various operating conditions on every continent

- High track geometry durability and resistance to track buckling thanks to dynamic track stabilisation

- Reduces speed restrictions: optimised availability of the infrastructure following maintenance and dynamic track stabilisation

- The frame is designed to maintain the heaviest types of superstructure (heavy haul lines)

- High availability thanks to a top speed of 100 km/h during running mode under own power

- Approved for line category C2 (axle loads ≤20 t)

Fonctionnalités

Profiter des avantages de la standardisation grâce au ModularCustomizing

Les machines issues de notre catégorie « ModularCustomizing » sont construites selon une stratégie de plateforme. Cela apporte un haut niveau d’efficacité en termes d’entretien et de gestion des pièces de rechange mais également en termes de formation et d’agrément, tout en conservant un haut degré de personnalisation. Plus de 300 variantes de machines selon le principe du jeu de construction. Des milliers de possibilités de configurations.