- Infrastructure

- Conventional lines

- High speed

- Field of application

- Ballast bed

- Turnout

- Track

- Working mode

- Spot maintenance

Unimat Combi 08-275

Cyclic action single-sleeper levelling, lifting, lining and tamping machine with three-rail lifting and integrated ploughing and sweeping trailer for plain track and turnouts

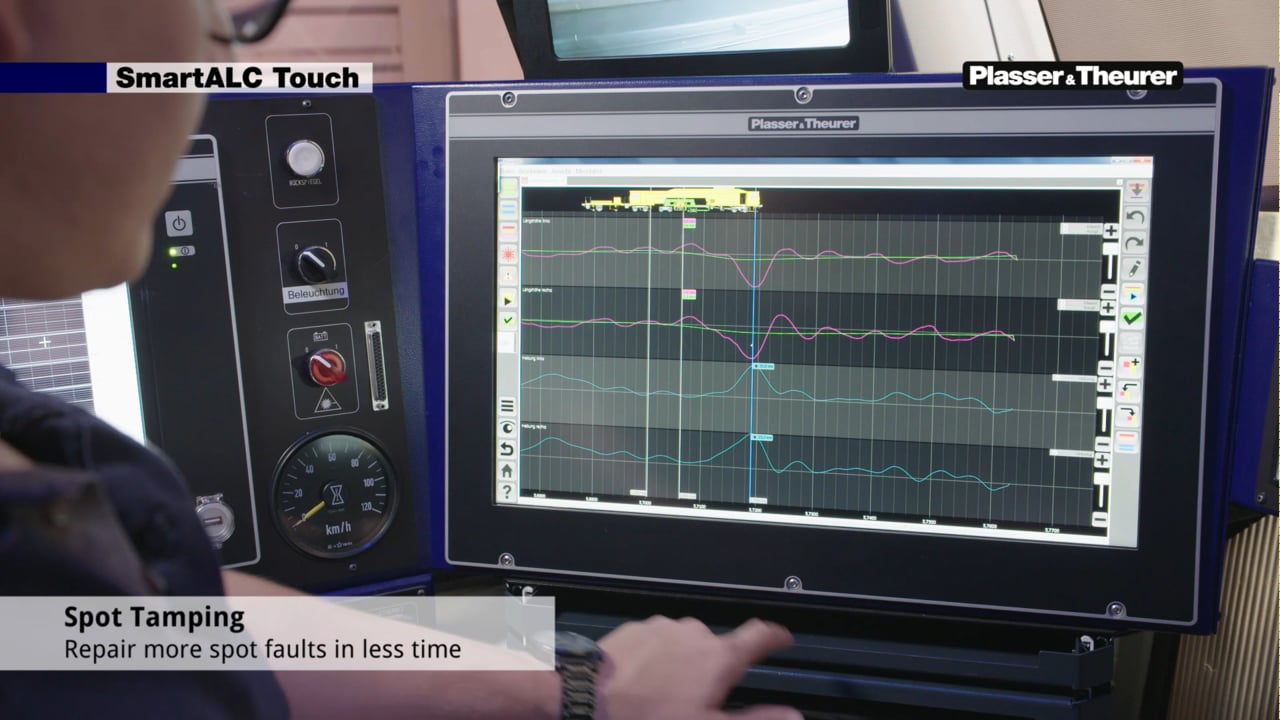

SmartALC

The standard in user-friendliness and process reliability: the track-geometry guiding computer provides ultimate operating comfort. Equipped with the SmartALC, tamping machines can work according to the precision method or the compensation method. Operators can select one of four pre-defined user profiles provided by the SmartALC to ensure their needs are met perfectly. Using AutoSync, for example, the machine automatically detects track defects.

more about Plasser & Theurer tamping technologyFeatures

Quality cuts costs: our machines turn a tidy profit

To date, Plasser & Theurer has supplied 17,700 machines. Most of them are still in operation. This attests to the quality of the machines and the value of our Customer Services’ life-long machine and fleet support. Plus, it proves that high quality ensures high cost-efficiency: machines that have been in operation for 20 or 30 years paid off years ago.