- Infrastructure

- Conventional lines

- Heavy haul

- High speed

- Industrial railways

- Line with steep gradients

- Field of application

- Ballast bed

- Turnout

- Plain-line track

- Tunnel

- Working mode

- Continuous action

Highlights

- Complete maintenance of plain-line tracks and turnouts: ballasting, tamping, profiling, stabilizing

- New operating concept allows both tamping operators to work in one cab: simplified coordination and communication, improved working comfort, and increased safety

- Optimum view of the work units thanks to 24 cameras: camera images on 6 screens at the co-tamping operator’s workspace - Hybrid drive concept: use of the overhead contact line or diesel. The machine can be operated in a carbon-neutral way for working and transfer travel.

- Efficient energy transfer thanks to shorter hydraulic lines and reduced transmission losses.

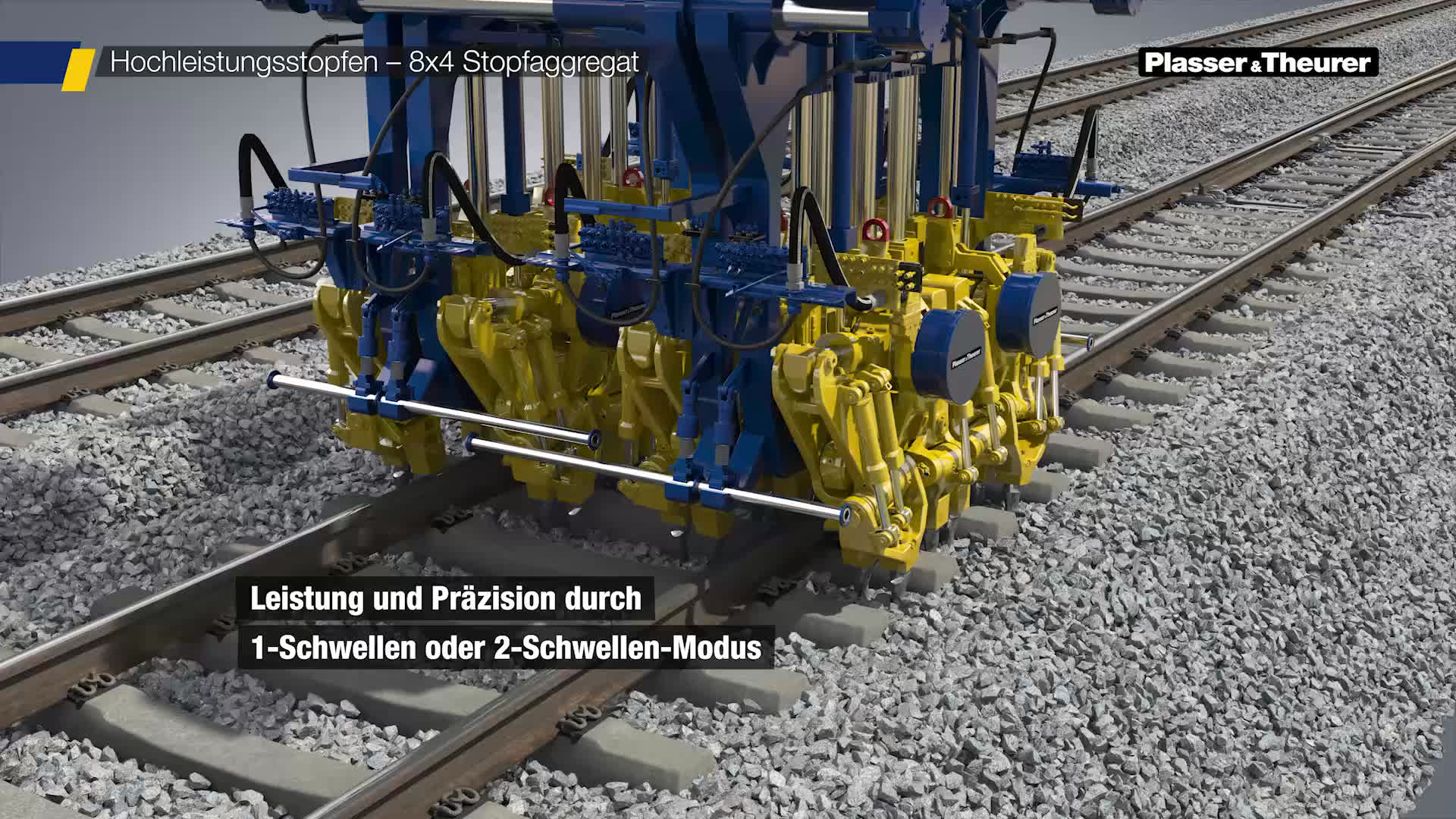

- 8x4 tamping unit: high performance of 2-sleeper tamping with maximum flexibility in 1-sleeper mode

- Optimum use and distribution of ballast during maintenance – spot ballasting possible

- Functional positioning of machine elements to increase efficiency for maintenance and operation

Technical data

Series: Unimat 09-8x4/4S BR-Dynamic E³

To view the technical data and download a factsheet on this machine, please enter your contact details.

Gallery

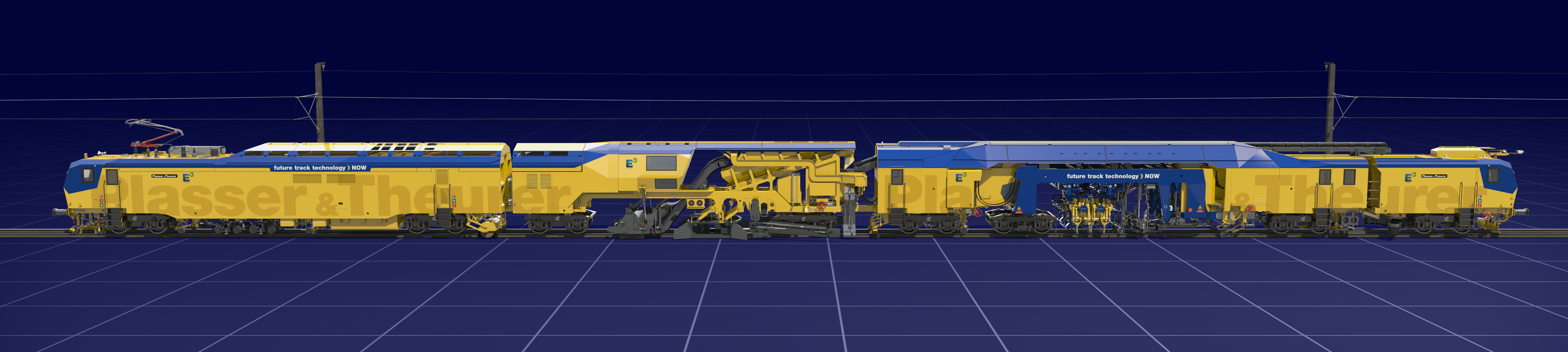

Unimat 09-8x4/4S BR-Dynamic E³

Machine illustration

Unimat 09-8x4/4S BR-Dynamic E³

In all areas such as its machine concept, technology, and ergonomic design, the Unimat 09-8x4/4S BR Dynamic E³ combines time-tested, state-of-the-art, and innovative components that soon prove their usefulness in practice. With more than eight technological highlights, the machine perfectly represents our iaf slogan “future track technology – NOW”. On that note: ready on the turnout, steady, go!

Unimat 09-8x4/4S BR-Dynamic E³: technological highlights at a glance

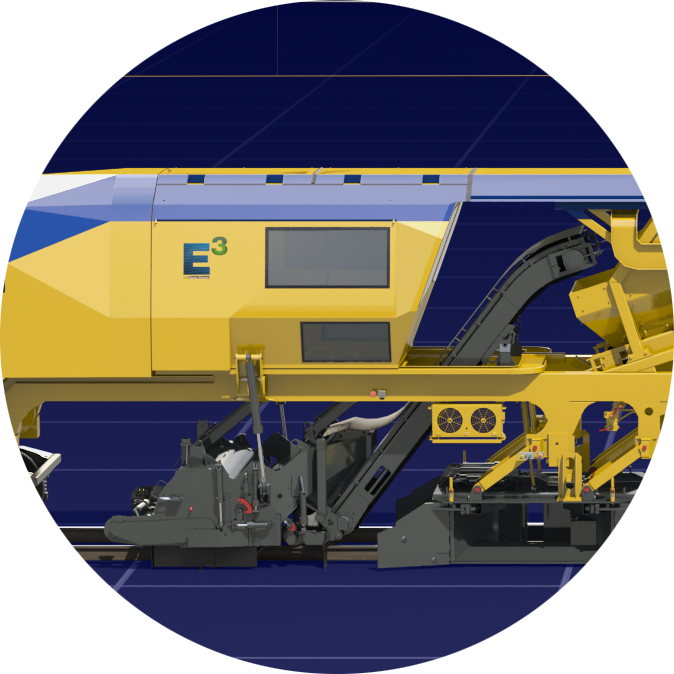

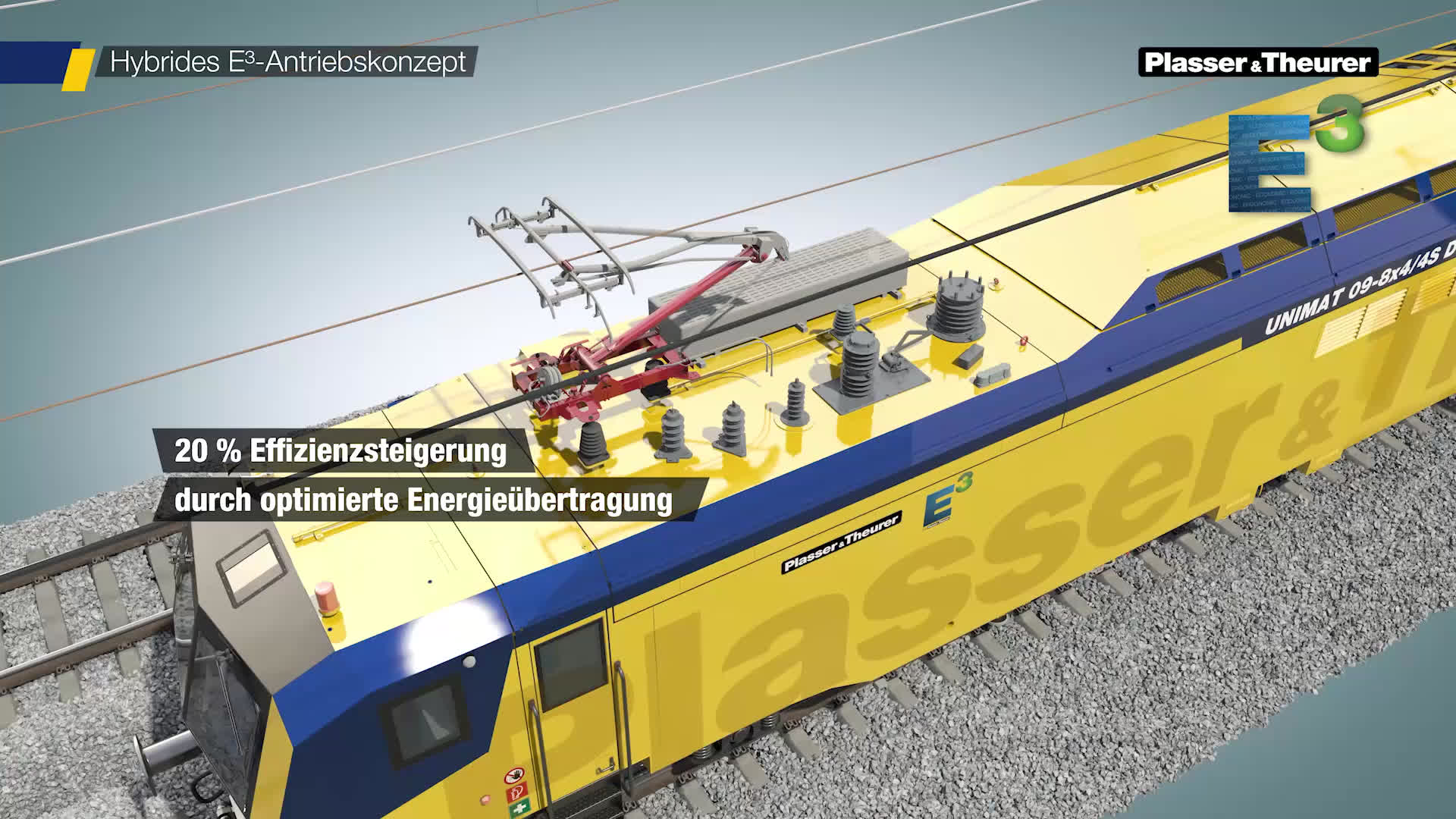

Hybrid E³ drive concept

Prepared for today’s demands: the Unimat 09-8x4/4S BR Dynamic E³ is driven by the revolutionary new E³ hybrid technology. In addition to the conventional drive system, the machine can be fully electrically powered during running and working mode. All rotary motions are powered fully electrically. Only a few linear motions remain hydraulically powered. The drive technology reduces hydraulic oil consumption by 80%. Transfer travel using carbon-neutral traction current lowers diesel consumption drastically. Additionally, E³ reduces noise emissions significantly and thus increases line-side residents' acceptance of the machine.

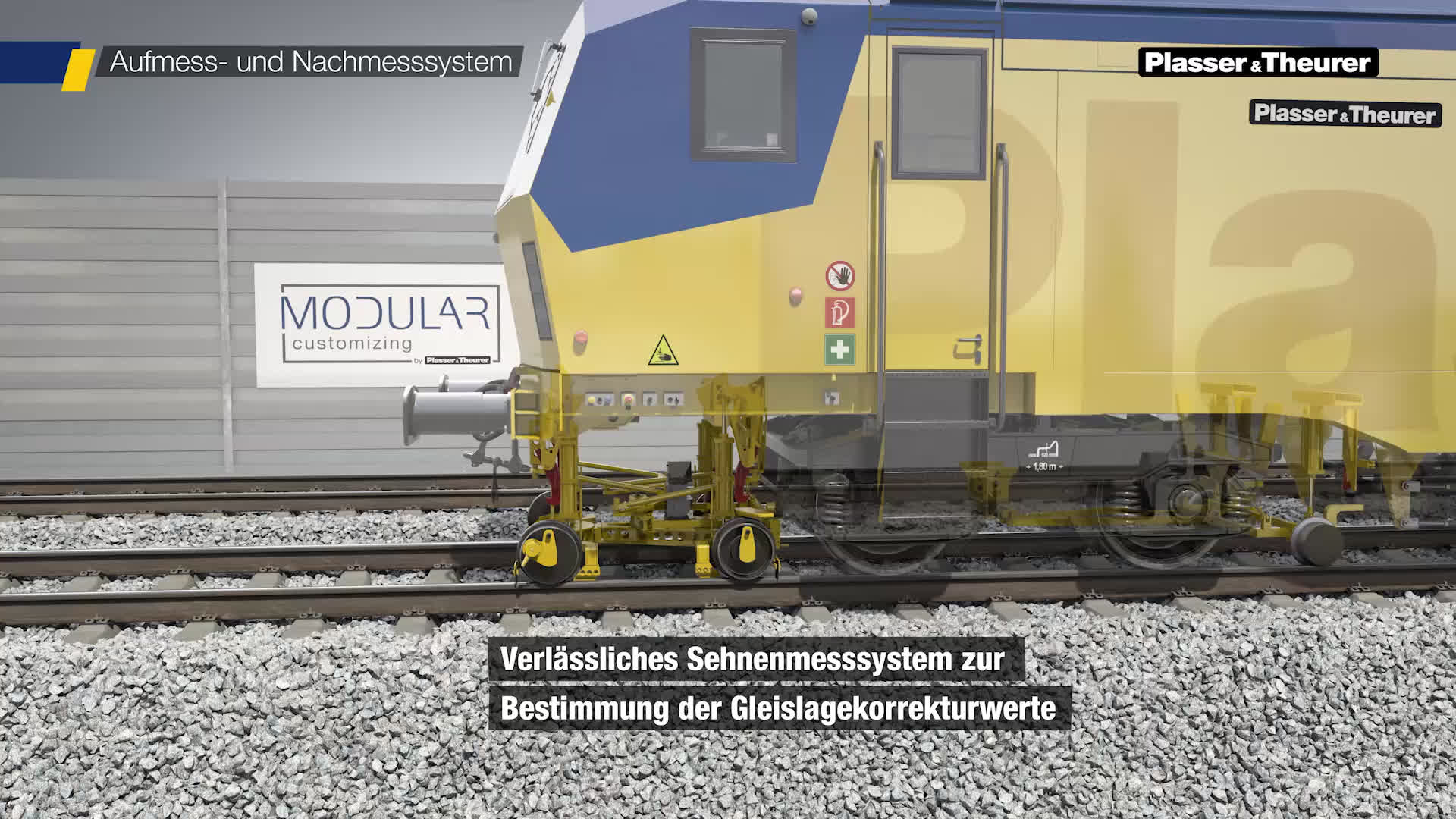

Surveying and recording measuring system

In addition to the conventional chord measuring system, the machine is fitted with the future-proof technology for precise and comprehensive measuring results: the inertial measuring unit mounted on a two-axle trolley. The IMU records a space curve that is assigned a relation to the rails via mechanical track gauge measuring. The compact system set-up enables complete post-measuring with little space required. Further, it is possible to survey the track geometry at speeds of up to 60 km/h prior to track correction. This saves a significant amount of time in daily operations. The system also enables a precise depiction of long-wave faults (alignment and longitudinal level faults for the wavelength ranges D1 and D2).

Two DGS units increase working speed

Dynamic track stabilization has become indispensable to sustainable track maintenance. This is all the more important as traffic loads increase. High-speed lines are particularly affected. The stabilizing units rearrange the ballast stones into a more homogeneous structure. This means that the dynamic forces produced by rail traffic are more evenly distributed within the formation. Therefore, there is no longer any need for speed restrictions after tamping. In addition, controlled settlement considerably increases the track panel’s lateral track resistance. For even more homogeneous track quality and for more precise stabilizing ramps and transitions, the Unimat 09-8x4/4S BR Dynamic E³ is equipped with another option: Variable Impact Force, which allows the impact force to be regulated continuously from 0 to 100 per cent.

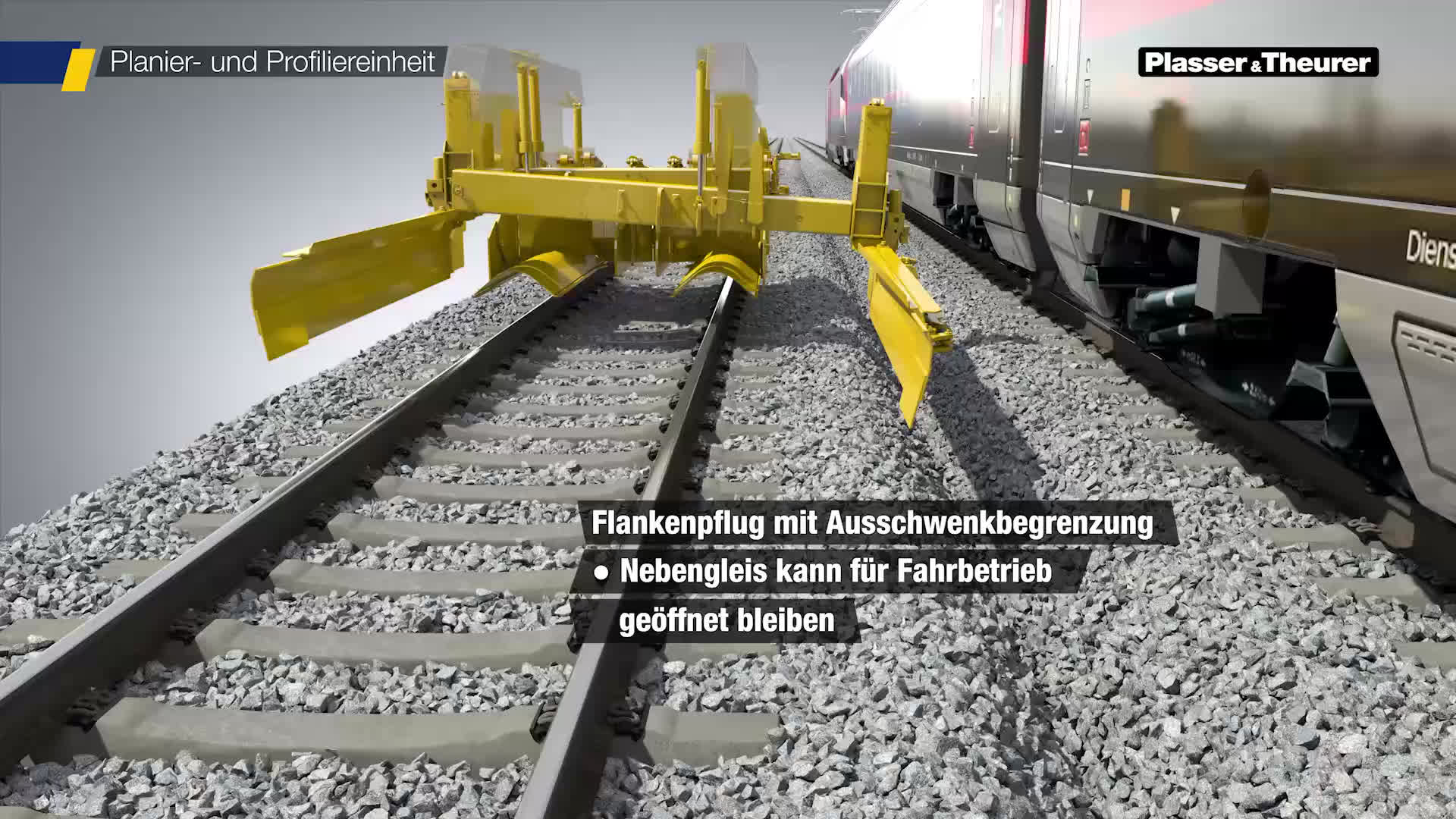

Levelling and profile finishing unit

For ensuring the highest level of tamping quality and sustainability, the Unimat 09-8x4/4S BR Dynamic E³ comprises time-tested technologies for ploughing, sweeping, profiling, and ballast management. Surplus ballast is systematically collected, stored (approx. 9 m³ hopper capacity), distributed, and discharged via plough, sweeper, and profiling units. The combined machine concept uses existing ballast sustainably and replaces ballast in front of the tamping unit in a targeted manner. This enables tamping in large areas without interruptions due to external ballast placement using ballast trains. This machine concept includes a shoulder plough with a slewing limiter to prevent infringements of the structure gauge and a centre plough for re-arranging track ballast on the ballast crown. The new sweeper brush no longer needs to be changed separately for wooden and concrete sleepers. It adjusts at the push of a button.

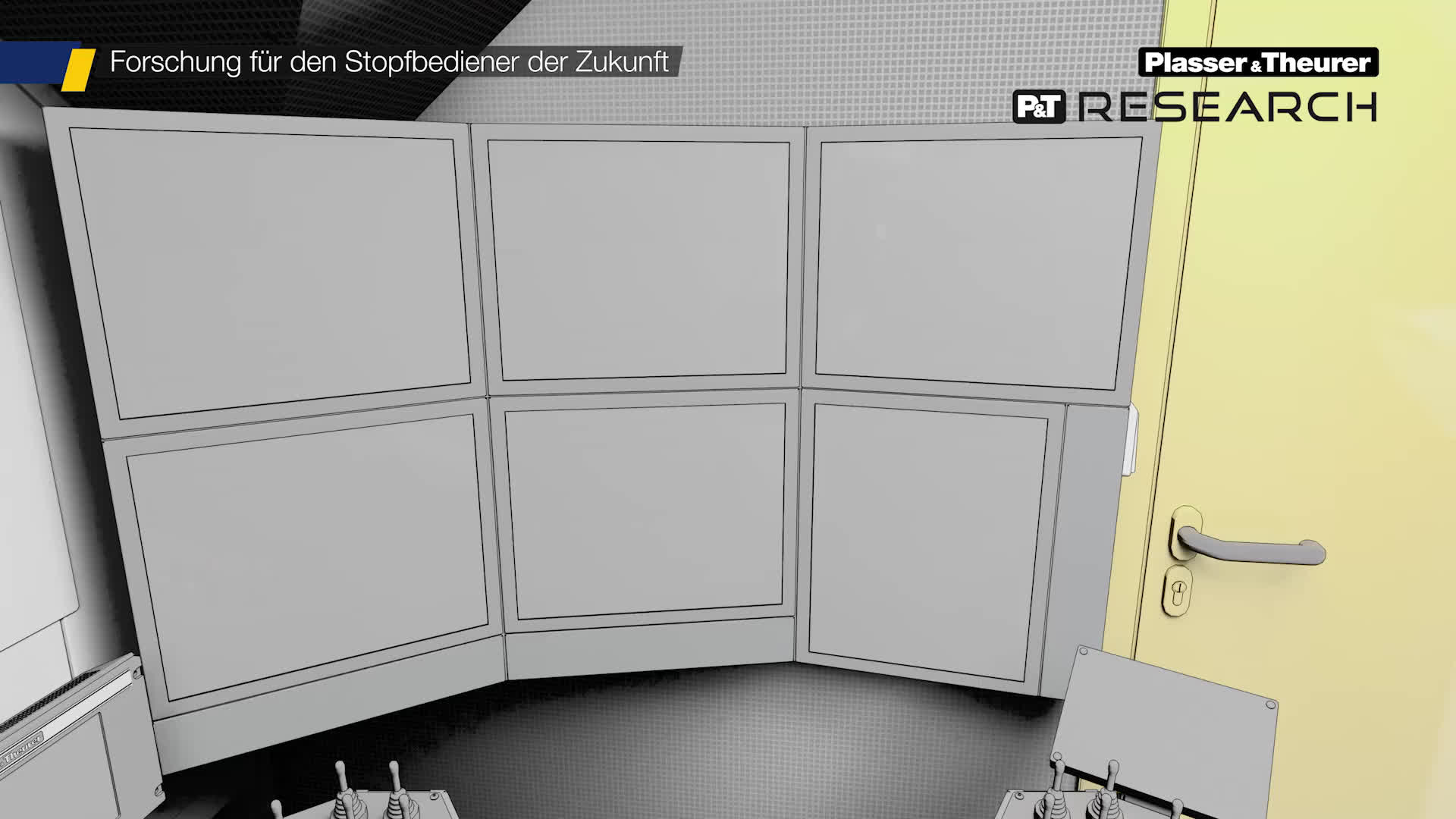

Research for the tamping operator of the future

The Unimat 09-8x4/4S BR Dynamic E³ has a variety of functions, yet its operation is simple and clearly structured. Furthermore, this machine comprises another innovative concept which has not existed in this form and design before: only one work cab. The co-tamping operator sits in the same cab as the main tamping operator and controls the lifting and lining unit, which they can see digitally on six different screens. This has several advantages. The co-tamping operator sits on the continuously moving part of the machine. The 24 high-resolution cameras allow for a better view of the working area compared to an “analogue” workplace. Communication and coordination between the operators is improved.

High-capacity tamping with the 8x4 tamping unit

An entirely new category in the field of universal tamping technology, the 8x4 tamping unit is equipped with eight independent tamping unit segments and tiltable tamping tines. The continuous-action 2-sleeper tamping machine offers a newly developed design with increased freedom of motion, tamping depth, and squeezing distance. It is possible to switch to 1-sleeper mode at any time. This adds value, especially when working on hollow sleepers, where the point machine is located, or on double sleepers. Tamping double-slip turnouts and turnouts with a movable-point frog is turnout tamping at its finest. The 8x4 tamping unit easily masters this task using its power reserves and versatility. Thanks to these features, the machine combines the high performance of 2-sleeper tamping with maximum flexibility in 1-sleeper mode.

Complete ballast management

For ensuring the highest level of tamping quality and sustainability, the Unimat 09-8x4/4S BR Dynamic E³ comprises time-tested technologies for ploughing, sweeping, profiling, and ballast management. Surplus ballast is systematically collected, stored (approx. 9 m³ hopper capacity), distributed, and discharged via plough, sweeper, and profiling units. The combined machine concept uses existing ballast sustainably and replaces ballast in front of the tamping unit in a targeted manner. This enables tamping in large areas without interruptions due to external ballast placement using ballast trains. This machine concept includes a shoulder plough with a slewing limiter to prevent infringements of the structure gauge and a centre plough for re-arranging track ballast on the ballast crown. The new sweeper brush no longer needs to be changed separately for wooden and concrete sleepers. It adjusts at the push of a button.

Crew area for breaks and mobile office on track

The Unimat 09-8x4/4S BR Dynamic E³ has an ultra-modern compartment that provides room for six people and features all the necessary amenities: WC, kitchenette, seating area, heated lockers, and a "digital workplace”. This area can be used for quality monitoring or for training. Of course, the new crew area complies with all occupational health and safety regulations. Then there is also a workbench for performing minor repairs.

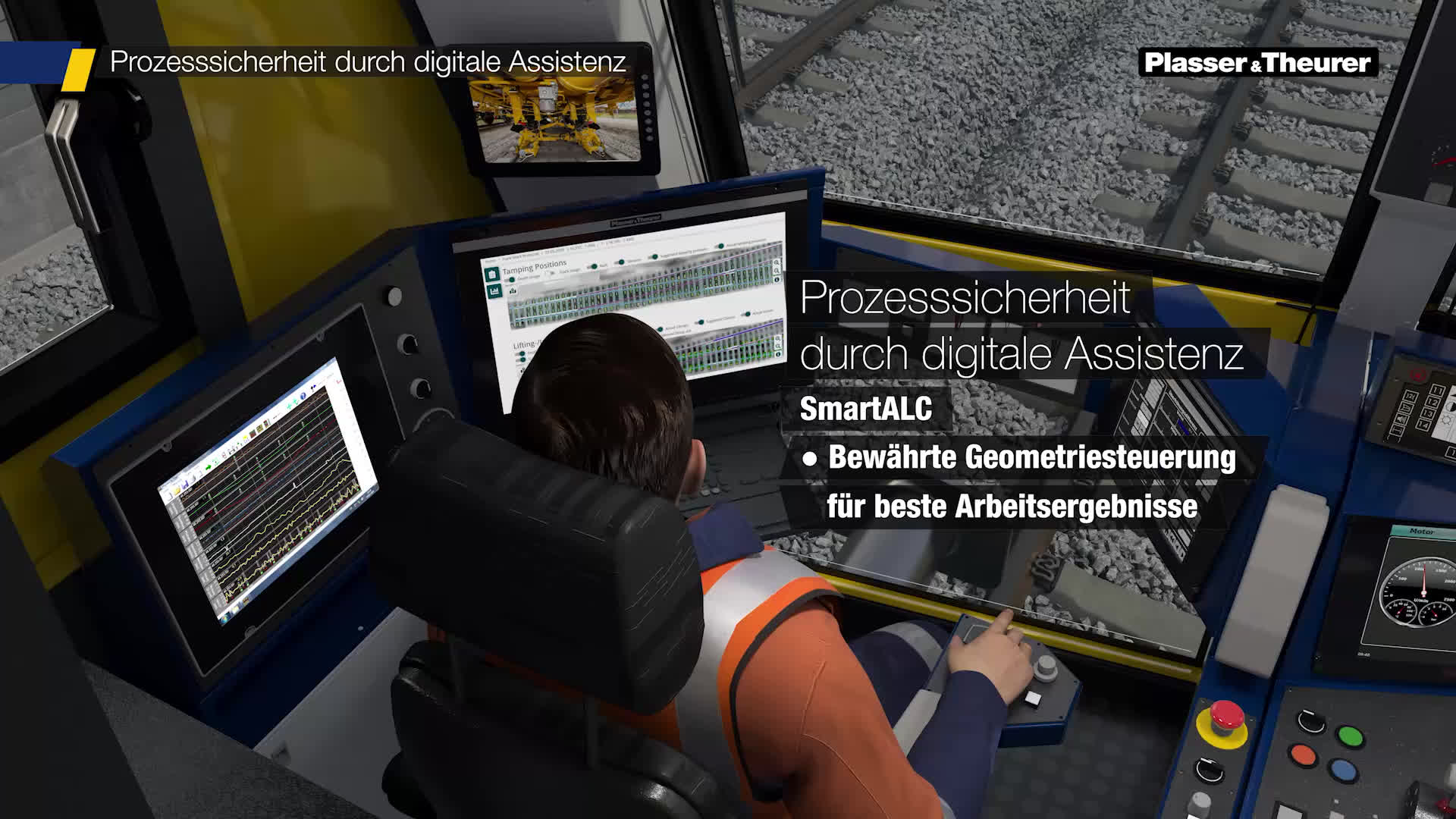

Digital assistance provides process reliability

Plasser & Theurer currently offers two SmartTamping options: the intelligent tamping assistance system Plasser TampingAssistant and the Plasser TampingReport. The Unimat 09-8x4/4S BR Dynamic E³ is equipped with both of them. In addition to the result report of the Data Recording Processor (DRP), the Plasser TampingReport provides you with more detailed information on work sequences. Tamping reports provide proof of technologically correct maintenance and can serve as basis for strategic decision-making. The reports provide detailed information that helps you to optimize and expand the planning of future maintenance activities. Highly customizable display options are available both for the back office and on the machine itself. You can hide and display individual tamping positions, lifting and lining positions, corresponding values, and the obstacles detected while viewing them using the continuous zoom function.

Features

Individual Design for your individualized machine

When it comes to complex high-capacity machines, the requirements of machine operating companies do vary. Country-specific criteria and individual needs are equally important. We satisfy your special requirements with Individual Design machines. This means we design and manufacture machines tailored to you. In particular, your experiences in daily operation shape the final product.

Illustrations and descriptions may contain optional equipment. We reserve the right to make changes as technology develops.