Highlights

- Maximum flexibility in the turnout thanks to the pivoting tamping unit, tamping unit segments that can be lowered individually, and tilting tamping tines

- The frame is designed to treat the heaviest types of superstructure (heavy-haul lines)

- Reaches the worksite fast thanks to a maximum speed of 100 km/h during self-propelled transfer travel

- Post-measuring while working eliminates an extra measuring run

- The world’s leading tamping technology – tested under various operating conditions on every continent

- Machine and cabs in state-of-the-art design and in line with ergonomic aspects (ergonomic, user-friendly, clear layout, innovative)

- Fast approval at reduced cost thanks to the use of standardized machine components and systems

- Simplified maintenance thanks to standardized assemblies

Technical data

Series: Unimat 08-4x4/4S

To view the technical data and download a factsheet on this machine, please enter your contact details.

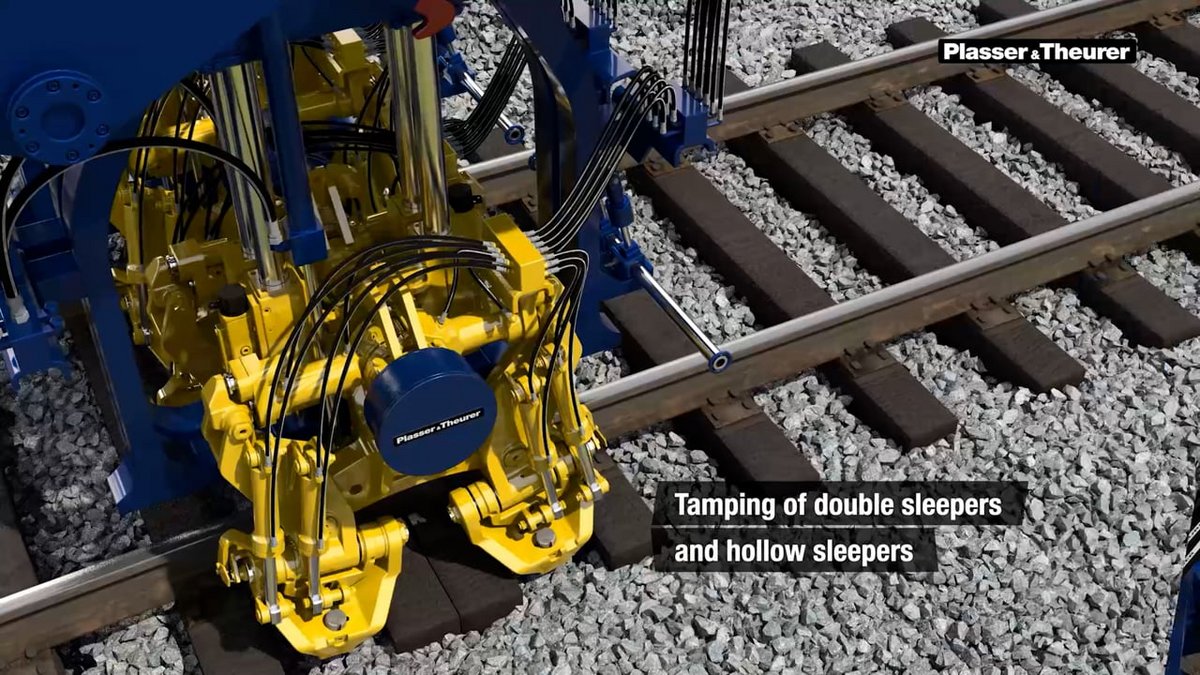

4X4 tamping unit

Setting the standard in turnout maintenance

Time-tested working parameters for optimal tamping results: The Unimat’s universal tamping unit has been optimized to meet the special requirements of turnout maintenance. You are prepared for any obstacle: the split-head technology makes it possible to shift each of the four tamping unit segments individually and sideways. If there is an obstacle in the turnout, the 16 tamping tines simply tilt upwards.

Gallery

Unimat 08-4x4/4S

Machine illustration

Unimat 08-4x4/4S

Properties

Enjoy the benefits of standardization with ModularCustomizing

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.

Illustrations and descriptions may contain optional equipment. We reserve the right to make changes as technology develops.