- Infrastructure

- Conventional lines

- Heavy haul

- High speed

- Line with steep gradients

- Field of application

- Ballast bed

- Turnout

- Plain-line track

- Working mode

- Continuous action

Highlights

- Expands the function of your machine modularly

- Creates a high-quality and homogeneously compacted ballast bed

- High track geometry durability and resistance to track buckling

- Restoration of the required lateral track resistance after tamping

- Increase the service life of track infrastructure and reduce life cycle costs

- Up to 30% longer maintenance cycles

- Optimized track infrastructure availability after maintenance

- Elimination or significant reduction of lines subject to speed restrictions thanks to systematically controlled initial track settlement

Technical data

To view the technical data and download a factsheet on this machine, please enter your contact details.

Gallery

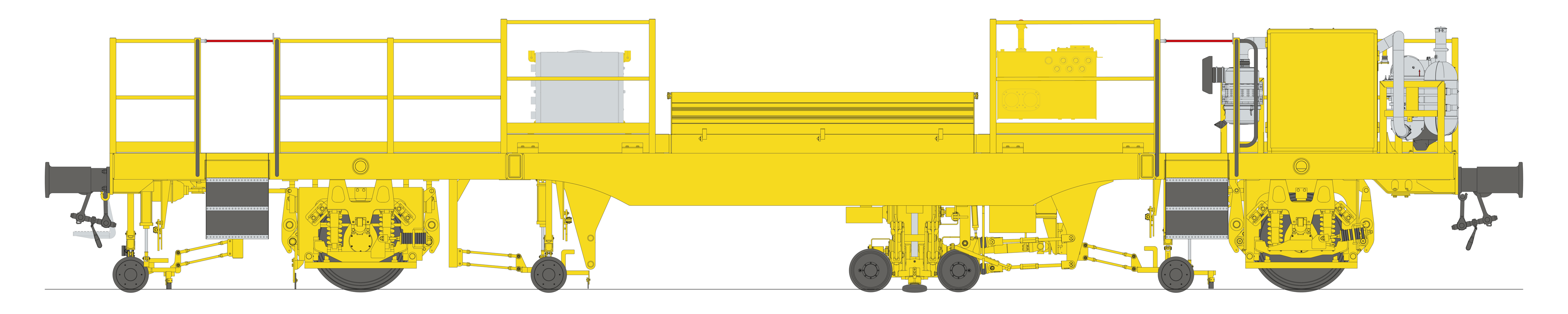

Plasser StabilizingTrailer

Machine illustration

Plasser StabilizingTrailer

zoomInzoomOut

Enjoy the benefits of standardization with ModularCustomizing

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.

Illustrations and descriptions may contain optional equipment. We reserve the right to make changes as technology develops.