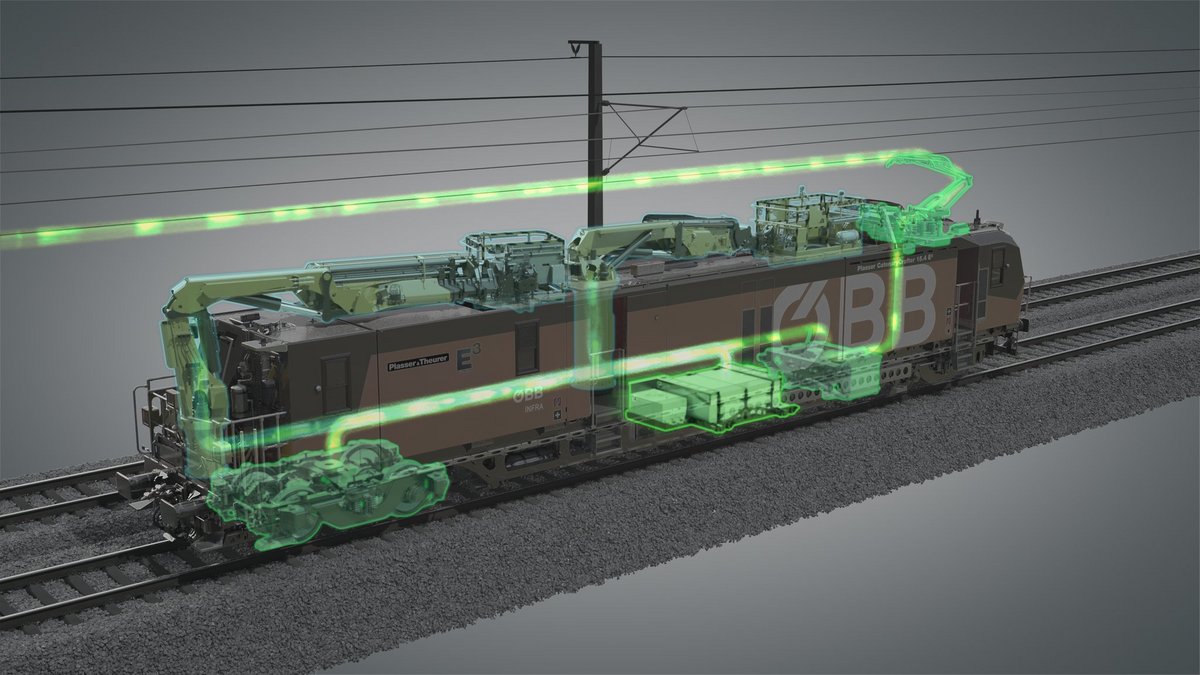

The largest single order in our company’s history: Plasser & Theurer will supply a highly modern fleet of maintenance vehicles to the infrastructure undertaking in the European Union’s most rail-friendly country. The ÖBB Infrastruktur fleet has entered a new era, and there are three pillars underlying it: a hybrid E³ drive concept for emission-free working on-site, improved ergonomic design, and modular design.

Railway paradise Austria: a new green maintenance fleet for ÖBB

Austria is the EU’s number one country for rail services: punctuality and passenger satisfaction are at their highest level, and more people travel by rail in Austria than anywhere else in the EU. This was made possible thanks to the federal government’s investments in railway infrastructure amounting to more than three billion euros per year. The country has committed to continuing its investments in its rail network in the years to come.

To ensure seamless rail services on new lines, ÖBB-Infrastruktur is renewing its entire maintenance vehicle fleet. In addition to ensuring maintenance on new lines and complex tunnel sections, ÖBB-Infrastruktur prioritises expanded functionality along with increased cost efficiency and sustainability. Plasser & Theurer came out on top in the EU-wide call for tenders. The company will supply 56 vehicles to ÖBB-Infrastruktur, with a purchase option available for an additional 46. It is the largest single order in the almost 70-year history of Plasser & Theurer, and it is the dawn of a new era in railbound maintenance vehicles.

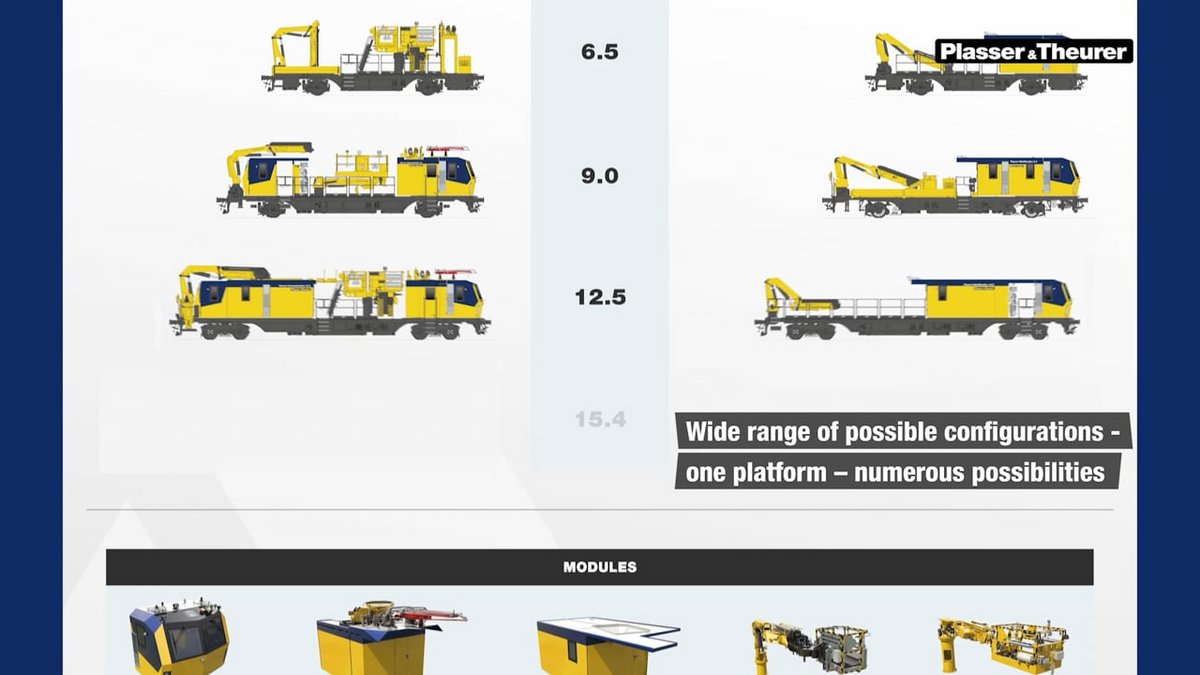

The vehicles were optimised in line with ÖBB-Infrastruktur’s wishes and experiences using the modular design system.

Modular standards, individual configurations

In the past, machines were treated as one-of-a-kind items in planning and production. Thanks to ModularCustomizing, important processes that are part of production, approvals, and maintenance will be simplified and standardised. It provides ÖBB Infrastruktur with several more advantages in addition to maximum flexibility and being able to adapt machines to its needs.

For example, a standard carrier vehicle will be equipped with individual mounted structures (modules); this reduces the costs of spare parts and maintenance significantly. Plasser & Theurer will supply three types of vehicles. ÖBB Infrastruktur will have a high- performance maintenance vehicle fleet, with three types of vehicles instead of 12, based on a uniform operating concept. This simplifies maintenance and reduces the costs of training and staff.

40 years of expertise in contact line installation

ÖBB has been counting on Plasser & Theurer maintenance machines since the 1980s. Both partners have decades of experience which went into developing and configuring the new vehicles. It was important to involve the employees, engineers, and technicians who work with these machines every day in creating the requirements specification for the new fleet. That made it possible to optimise work sequences and massively improve occupational safety and ergonomic design while reducing the number of vehicle types.