The CO₂-neutral alternative to diesel

HVO100 is a synthetic fuel produced through the hydrogenation of vegetable oils. It has similar properties to conventional diesel. Its great advantage is that it is produced on the basis of renewable feedstocks and is therefore virtually climate-neutral. Only plant and animal residues may be used in order to eliminate competition with food production. Compared to diesel, it saves 70 to 90% of global CO2 emissions. Local emissions, such as fine dust, hydrocarbons, carbon monoxide, and nitrogen oxides, are also significantly reduced.

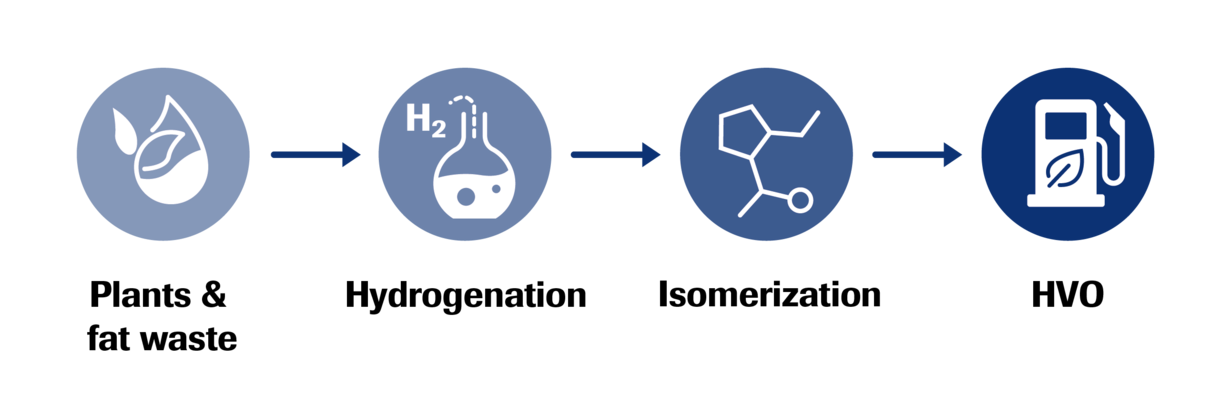

HVO production process (source: https://toolfuel.eu/synthetischer-diesel-hvo/ [German only])

All machines are now available for HVO100 use

Operation with HVO100, in accordance with EN 15940, is now possible for all new Plasser & Theurer machines - regardless of the machine category.

Significant reductions in emissions can therefore be achieved without restrictions. The machines can be used as usual. No additional training or changes to their operation are required. Depending on the components installed on the machine, additional one-off costs may be incurred in exceptional cases.

As a bridging technology, biofuel can already be used in application scenarios in which emission-free E³ machines are not yet a viable option.

The synthetic fuel offers even more advantages: HVO100 can be used all year round. A changeover as with winter and summer diesel is not necessary. In addition, there is no risk of diesel bug infestation with HVO100 during long-term storage.

HVO100 in accordance with EN 15940

meets the following EU directives:

- Clean Vehicles Directive (CVD) - EU 2019/1161 - 2009/33/EC

- Renewable Energy Directive (RED II/III) - 2018/2001/EU

- Ban on palm oil from RED II/III onwards

The use of HVO100 was tested for six months together with DB Netze. A GAF 746.0 track motor vehicle was used to test the effects of switching from diesel to HVO100 on the individual components and the overall machine system. Thanks to the MachineDataConnector (MDC) mounted on it, comparative data could be easily generated and compared.

The results show that the operation was not negatively affected by the changeover in any way. Fuel consumption is practically identical to diesel (16.1 l/h HVO compared to 16.2 l/h diesel). The behaviour of the HVO-powered machine was equivalent to its diesel-fuelled counterpart in practically all areas regarding the engine and machine operation.

Use of HVO100 on existing machines

An inspection of the components will determine whether your existing machine is HVO-compatible. Please contact Plasser & Theurer’s customer service at cs@plassertheurer.com.