Highlights

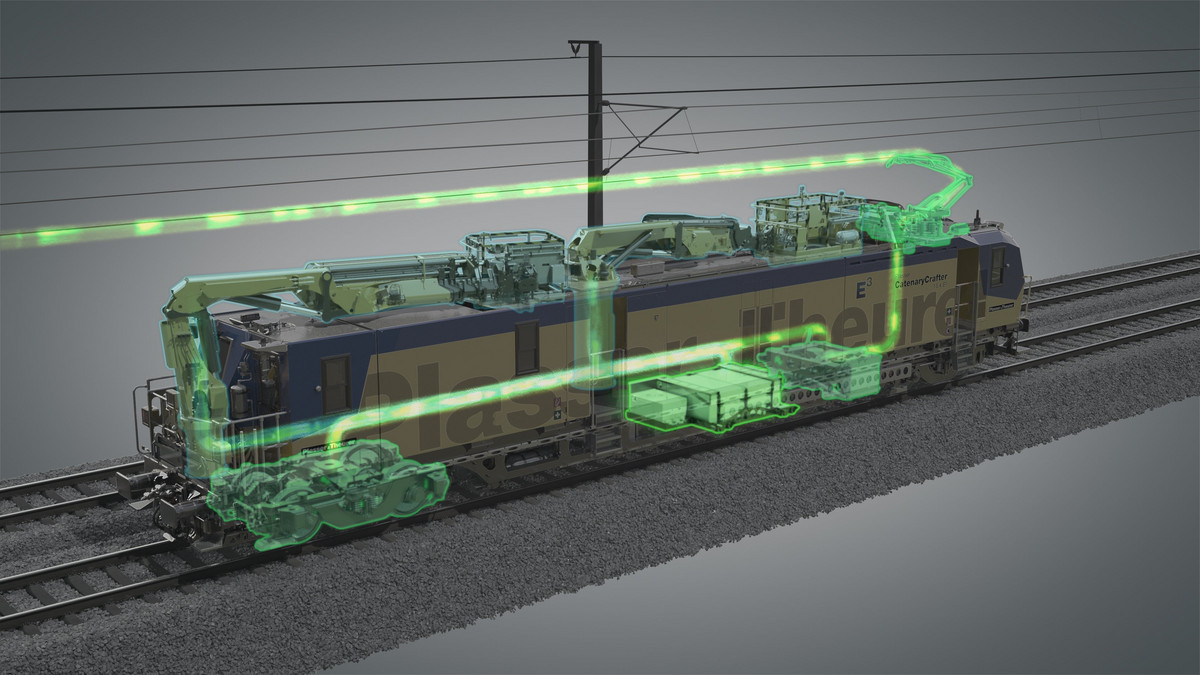

- Emission-free running and working thanks to energy supplied by the overhead contact line and a battery

- Diesel-electric power pack as an additional energy source

- Increased traction thanks to electric drive on all four axles

- High speeds when self-propelled and towed to reach the worksite quickly

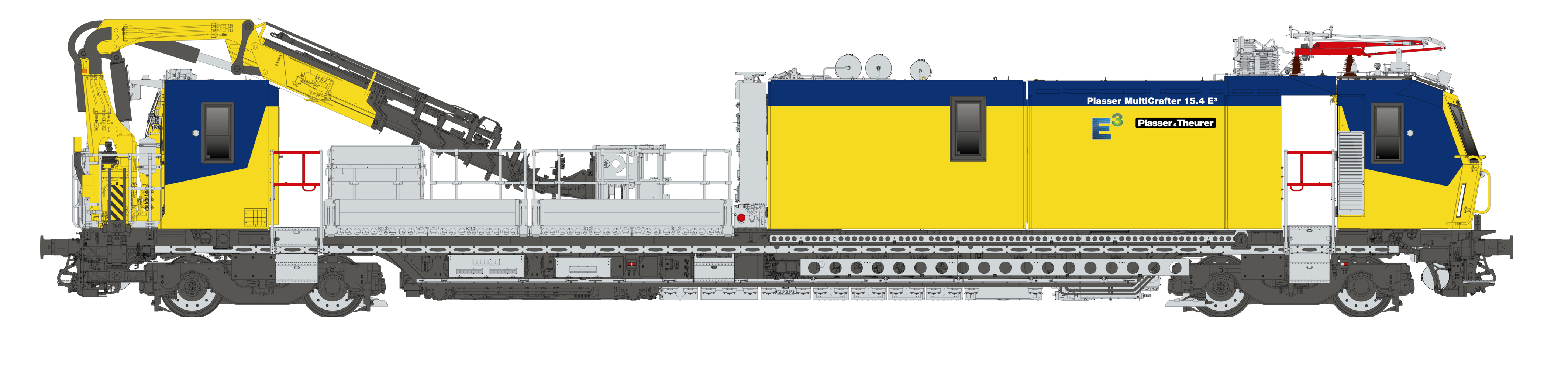

- Railway crane with high lifting moment and personnel basket stowed on the loading platform as well as lateral outriggers

- Loading platform with plug-in railing for transporting equipment and material

- Crew cab with kitchenette, seating, and sanitary facilities providing space for up to 11 people on the machine

- Possible to attach different snow removal equipment

- Integrated ETCS in combination with the national PZB train protection system

Technical data

Series: Plasser MultiCrafter 15.4 E³

To view the technical data and download a factsheet on this machine, please enter your contact details.

Gallery

Plasser MultiCrafter 15.4 E³ (sample configuration)

Machine illustration

Plasser MultiCrafter 15.4 E³ (sample configuration)

Enjoy the benefits of standardization with ModularCustomizing

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.

Economic – Ecologic – Ergonomic

The latest track maintenance machines use both the electrical energy from the contact wire and batteries to power the working drive. Our new E³ drive technologies reduce local emissions - of both pollutants and noise – to a minimum on the work site. Introduced in 2015, Plasser & Theurer’s E³ machines stand for: Economic – Ecologic – Ergonomic.

Illustrations and descriptions may contain optional equipment. We reserve the right to make changes as technology develops.