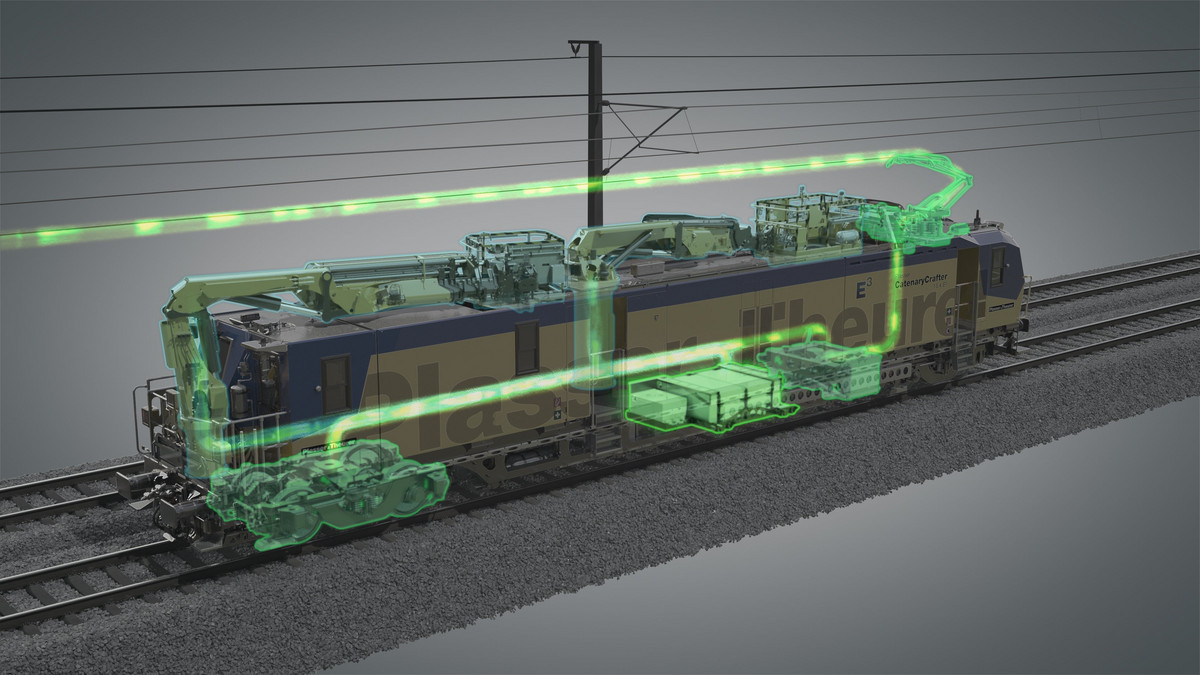

The eco-powerhouse for the overhead contact line

Safe working with slewing column lifting platform and railway crane

Worldwide proven ballast cleaning in a new, modular design

Brilliantly reliable ballast cleaning with the Plasser ScreenLiner 3100 series

Positioned under the track panel, the excavating chain produces a precise cut of the formation.

The lifting and slewing unit keeps the track panel in the desired position.

The screening unit separates high-quality ballast from fines.

In many places where replacing the ballast bed used to be necessary, nowadays the ballast can be reprocessed in a track-bound ballast cleaning machine.

Optional equipment: Dynamic track stabilization

Turnout cleaning without dismantling the turnout thanks to widening of the excavating unit

Optional equipment: Supply of new ballast

Optional equipment: Cutter bar transport device with assembly aid

Optional equipment: Dust-suppression system

Optional equipment: Camera systems for monitoring

Optional equipment: Sleeper crib excavator

Optional equipment: Workshop and crew cab

Track-bound technologies are more than 30% greener