- Infrastructure

- Conventional lines

- Heavy haul

- High speed

- Field of application

- Ballast bed

- Working mode

- Continuous action

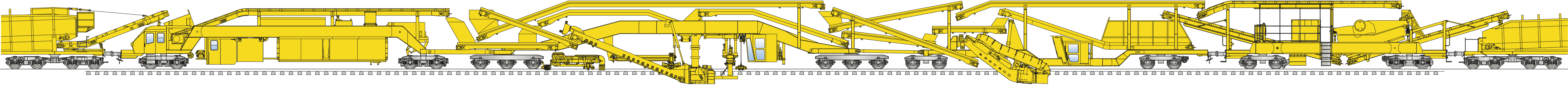

Unique on the world market, the innovative technology of the URM 700-2 enables us to fill a market niche by offering full turnout service. Cost-efficiency is the goal - not only when maintaining plain line track, but even more so when maintaining turnouts which often affects two tracks at the same time. The duration of track closures is a key factor, particularly for main-line railways. The URM 700-2 offers decisive advantages when managing tight schedules for turnout maintenance. There is no need to remove and reinstall the turnout. Both ballast cleaning and tamping in turnouts can be completed during one single shift. As soon as the work has been completed, the track section can be reopened for traffic.

Benefits of this technology

Our URM 700-2 ballast cleaning machine is the core technology for turnout maintenance. This machine makes it possible to clean the ballast bed without removing the turnout. Moreover, it allows for continuous working progress. In addition, it cleans the ballast shoulders. The machine is also suited for maintaining large high-speed turnouts with movable-point frog. Another advantage is that sections of track at connecting tracks and between turnouts can be cleaned in one pass.

Thanks to the fast and independent installation and removal of the excavating unit, the URM 700-2 works cost-efficiently on short sections of track.

- Short set-up times

- No need to cut the rails, neither at the start nor at the end of work.

- No full track closures - the time required for ballast cleaning in turnouts is reduced significantly.

Features

Individual Design for your individualized machine

When it comes to complex high-capacity machines, the requirements of machine operating companies do vary. Country-specific criteria and individual needs are equally important. We satisfy your special requirements with Individual Design machines. This means we design and manufacture machines tailored to you. In particular, your experiences in daily operation shape the final product.

Illustrations and descriptions may contain optional equipment. We reserve the right to make changes as technology develops.