Revolutionary track inspection from the air

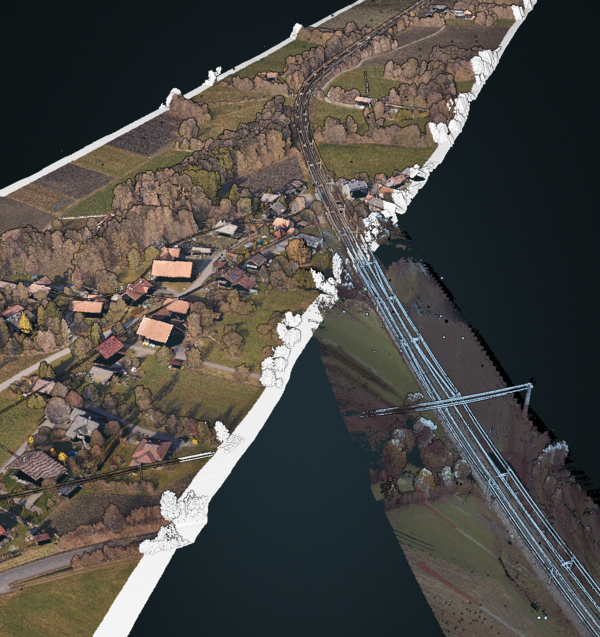

Unmanned aircraft systems (UAS), also known as drones, have become an indispensable tool for a number of industries. Due to their ability to collect highly precise data and detailed images across large distances, UAS have revolutionised the inspection, inventorying, and digitalisation of railway infrastructure. Intelligent software processes the enormous quantities of data in the background and provides a robust basis for decisions.

The benefits of UAS are clear: with their high-performance sensors, they capture railway tracks much faster, more comprehensively, and with more detail and accuracy than would be possible with conventional methods, such as inspections of the line. Equipped with several sensors precisely matched to the task, nothing escapes them within a radius of several hundred metres. They fly continuously above sections of track that are hundreds of kilometres long – over areas which are difficult to inspect on foot, such as rough terrain and mountains – reaching speeds of up to 120 km/h at an altitude between 80 and 100 metres.

The applications range from planning new track via monitoring construction progress, inventorying of installations, and regular inspections through to a quick survey in case of emergencies or natural disasters.

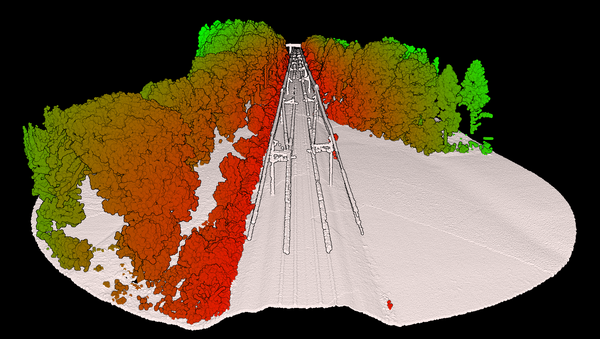

In this way, UAS make a valuable contribution to maintenance management (predictive maintenance). The more frequently a section is flown over, the more precisely changes in the infrastructure, vegetation, or terrain can be detected and thus optimised maintenance schedules drawn up.

UAS are the eyes, software is the brain

All flight movements and sensor data are recorded in a tamper-proof blockchain, ensuring correct and legally admissible documentation.

The payload of the UAS, consisting of laser scanner as well as RGB, multispectral, ultraviolet, and thermal cameras, provides large quantities of high-resolution images. More than a terabyte of data is generated for each hour of flight, and the subsequent processing would not be possible without AI-based software and powerful computers. The trained AI classifies different types of objects using image recognition, locates them based on the geographic coordinates, and discovers changes in their condition (anomalies). In this way, faults and anomalies are detected early, reported, and passed for maintenance.

Easy access to complex technologies

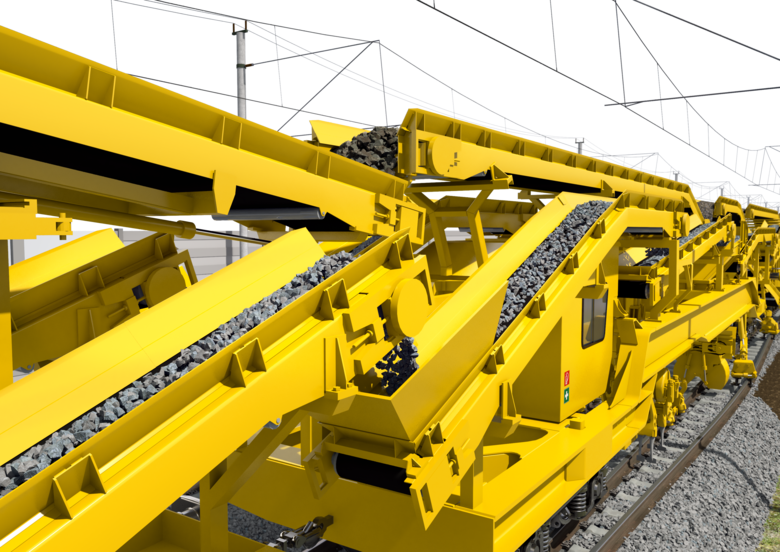

UAS flights are a practical complement to rail-bound measuring runs. By linking the data resulting from the UAS flight and the track inspection vehicle on the track, a comprehensive picture arises of the examined installations, and problem areas are detected early. To exploit the full potential of these complex technologies, Plasser & Theurer has set up the joint venture DRUM (Dynamic Rail Utilities Monitoring GmbH) together with SmartDigital. This makes it possible to bundle expert knowledge and provide infrastructure managers with easy access to high-quality data generation and data analysis, and all this in one end-to-end process. The customer does not need to grapple with topics such as permits from the national aviation authority, processing large quantities of data, or generating models, but can make use of the processed data straight away. In this way, UAS can fully play to their strength for planning, inventorying, condition monitoring, and maintenance.

![[Translate to Französisch:] [Translate to Französisch:]](/fileadmin/_processed_/a/9/csm_202109_Visualisierung_beim_Stopfen__1__f0921ecd25.png)