InnoTrans: PlasserSmartMaintenance

Plasser & Theurer is again present in the outdoor area of InnoTrans – two machines will be on display with only one of them a track maintenance machine proper. Digital products are picking up speed and create the basis for new ways forward.

Mechanised track construction and maintenance are setting their signals to digitalisation and a wider range of functions. Today’s track maintenance machines are advanced measuring equipment, auxiliary vehicle, living space and figurehead all in one. With this approach Plasser & Theurer meets the requirements of infrastructure managers, rail operation managers, contractors, workers and abutters – and in so doing, it is perceived as a representative of the rail transport system. In spite of all this, the tried and tested basic functions of lifting, lining and tamping – in other words of ensuring proper track geometry – are retained but follow new propulsion and control systems and communication paths that are interconnected in real time.

With the two machines on display, Plasser & Theurer will demonstrate this interlinkage and its mode of action.

Digital twin meets absolute track geometry

In the outdoor area Plasser & Theurer will show its EM100VT, the key champion of innovation for the development of digital products for railway tracks. An inertial track geometry measurement system is combined with a novel optical fixed-point procedure and GNSS/GPS georeference data. Previously, absolute track geometry could only be identified during special track possessions at walking speed. The new method is the first to capture absolute track geometry at speeds of 100 km/h and more – it sounds like a record-breaking achievement when we think of the former equipment for trackside surveying which had to be re-adjusted manually at every mast.

For the first time, this recording car sends data on absolute track geometry via the cloud directly to the maintenance machine! In future, the data will serve even more the optimising of asset and life-cycle management systems of rail infrastructure in a sustainable and holistic manner.

Universal tamping machine for tracks and turnouts

The Unimat 09-4x4/4S E³ on show heralds a new era of tamping machines. Some of the new features are visible at a glance, while the added value of many of them can only be seen in daily operation.

- Design: for many operators the cabin is their second home. Understandably, ergonomics and features for fatigue-free work have become increasingly important in equipping the machine. Optimised user friendliness thus is of great concern to Plasser & Theurer, with the ultimate aim of providing track maintenance machines that are more efficient and safer to work with and deliver a better overall result.

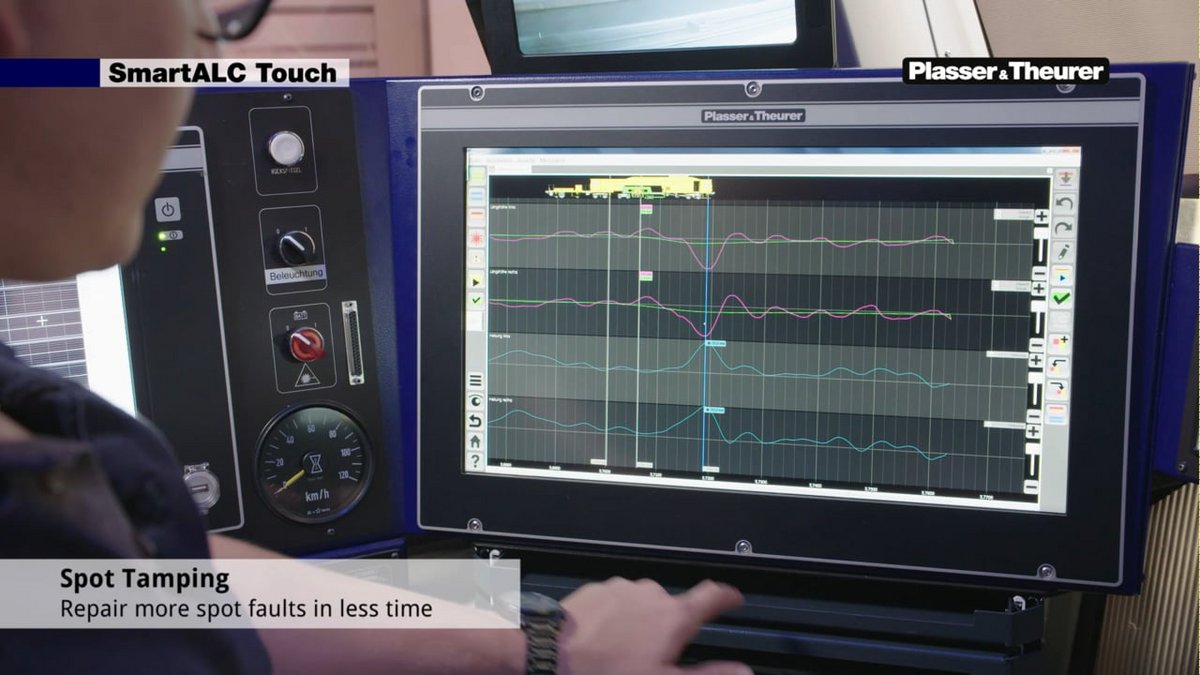

- SmartALC: as an automatic guiding computer for track geometry, SmartALC now offers a new spot tamping tool for targeted spot work in the track. In addition, the guiding computer will be upgraded with a BIM (Building Information Modelling) interface.

- PlasserSmartTamping – The Assistant: this assistant system, which was already demonstrated at the iaf in in Münster/Germany, relieves strain on operators by making clear recommendations on lifting and lining and on how to set the tamping units.

Individual configuration of your machine

On display at InnoTrans will be a tamping machine for tracks and turnouts that uses the new fully electronic E³ propulsion during work and transfer. Visitors will be invited to experience the individual configuration of a Unimat 09-4x4/4S with a VR configuration tool at our exhibition stand. They will be able to discover additional potential: an inertial measurement system for track geometry, i.e. the PlasserSmartTamping – The Assistant system, or a trailer module for sweeping and shifting ballast. These and many more features can be integrated into a tamping machine in future.

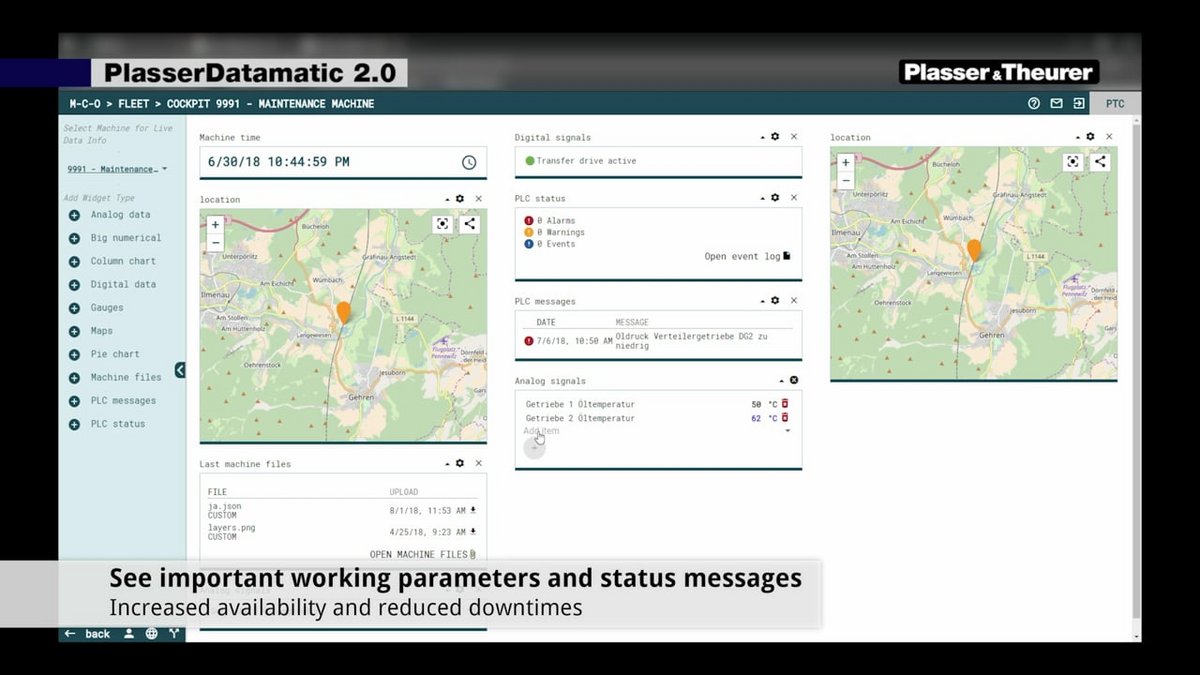

Datamatic 2.0 interconnects operation and maintenance

As a browser-based user front end, Datamatic 2.0 provides an individualised data mix in real time. A single machine is already a useful source of information. The cost advantage generated by the system is of course greater when one manages a whole fleet of machines. Live information, such as location of machine(s) and direction of work, supports dispatchers in daily work. Regular reporting of operational parameters and maintenance data form the basis for condition-based maintenance.

The new MachineMaintenanceGuide MMG is a digital maintenance record that communicates pdf reports directly to Datamatic 2.0, thus ensuring centralised collection of all servicing jobs done on a machine that is in daily use. This makes it easier for fleet managers to keep an overview of their machines.

Replacement tamping unit with servicing package

New Plasser & Theurer tamping units come with exceptionally long warranties of 24 months or 500,000 tamping cycles. Another benefit is a package of five visits (minimum) by a service engineer and an additional two years of support. This is how Plasser & Theurer’s after sales service is true to its motto ‘We care about your machine’. The common goal of these measures is to ensure more tamping cycles, reduce unexpected costs and extend the life of your machine.

The long-established company from Austria has thus enlarged its range of offers not only with new machine concepts but also with after sales programmes for the entire life cycle as well as with digital products that help get track maintenance into shape for a new era.