Radar: the "eye" of the machine

Research partners

Radar: the "eye" of the machine

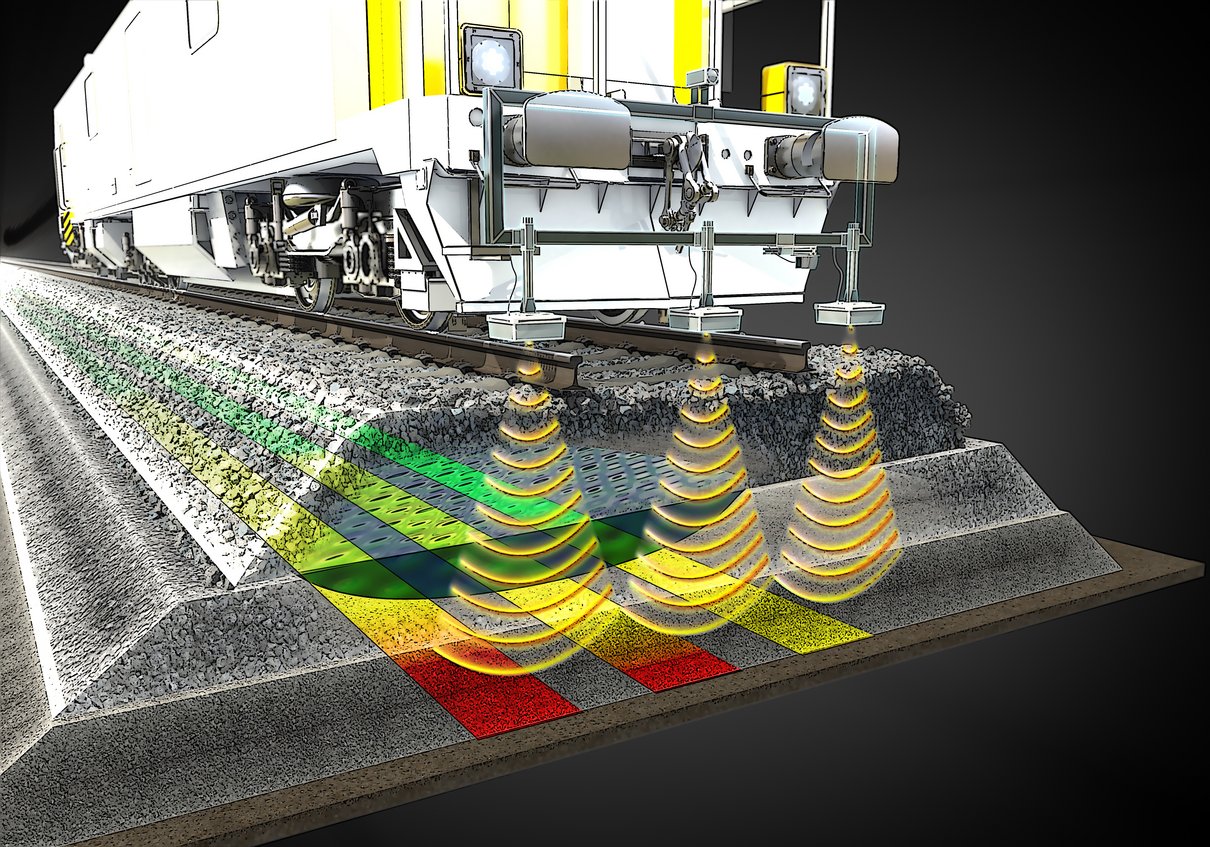

The word “radar” may make you think of air travel and parking assistants. But radars have also entered the field of railway, specifically in the form of ground penetrating radar (GPR), also known as georadar. Until now, GPR has been used primarily for preventive inspection of the track bed and the substructure. Thanks to advances in technology, even more possibilities are opening up now. For example, incorporating GPR into track maintenance machines is a concept with great potential.

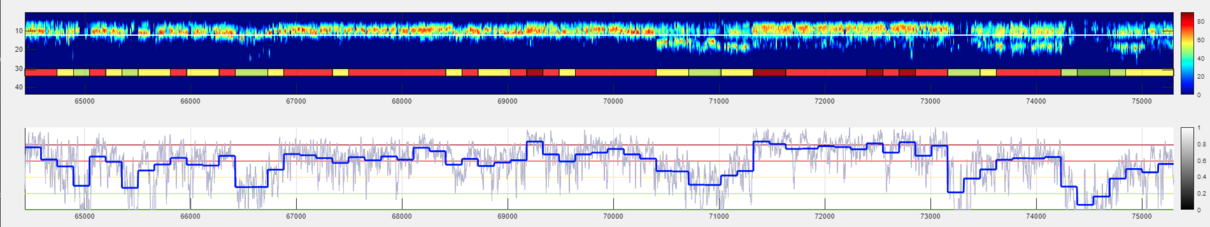

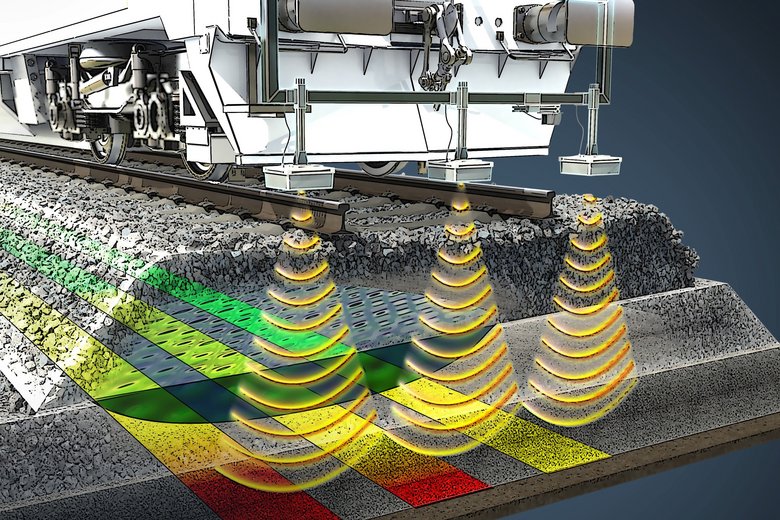

For some time, GPR measuring has been the standard procedure for ballast bed and subsoil inspection. GPR allows for a seamless, comprehensive analysis ranging from individual lines to entire railway networks; no line closures are required. During the analysis, it provides data on all relevant geotechnical parameters, such as the degree of moisture, the degree of ballast bed fouling, and the boundaries between ballast bed layers. This allows for detailed knowledge about the track, creating the basis for optimal maintenance planning. All of its advantages have made GPR an indispensable data source for infrastructure managers.

Today, the electronics of GPR devices are so powerful that they allow measuring speeds of up to 300 km/h without compromising data quality. As of late, technological advances in software have complemented those achieved in hardware. Until not too long ago, measuring data evaluation was a time-consuming process done by hand. Applying artificial intelligence (AI) eliminated this “bottleneck”. Software that is based on Unsupervised Machine Learning opens up new application scenarios by enabling high-quality, fast, and - most importantly - automatic measuring data evaluation.

A broad range of applications

In view of the advantages GPR offers, the next logical step is to combine it with other measuring systems, as testing with the EM100VT carrier vehicle has shown. A single measuring run does not only provide outer track geometry data: it also allows for a detailed insight into its “inner values”.

GPR can be used for preventive inspections and is also a useful addition to track maintenance machines. For instance, GPR is used for documenting track renewal work, such as the installation of a formation protective layer. For the purpose of providing proofs of work, track maintenance machines are already being equipped with GPR.

In addition, GPR data helps to plan operations for ballast cleaning and track renewal machines. Especially for such large machines, early detection of obstacles or dangers such as concrete foundations, cable ducts, and munition prevents costly standstills and damages and reduces the wear.

Track maintenance machines learn to “see” the world

Incorporating GPR into track maintenance machines certainly has great potential. This is why Plasser & Theurer recently initiated a technology partnership with Ground Control, a technology leader in the field of GPR in track maintenance. Right now, track maintenance machines are still “flying blindly” to a certain extent. In the future, an increasing number of machines will be able to use radar to “look into” the ballast and react to various conditions. We are curious to see further developments.