Blockchain for increased safety

Blockchain for increased safety

Using Blockchain in track construction?

Blockchain is known for being applied in the context of cryptocurrencies. Beyond that, “Distributed Ledger Technologies” that record transactions in a complete, correct, timely, and orderly manner offer other fascinating application scenarios. These technologies use cryptography to enable decentralised accounting.

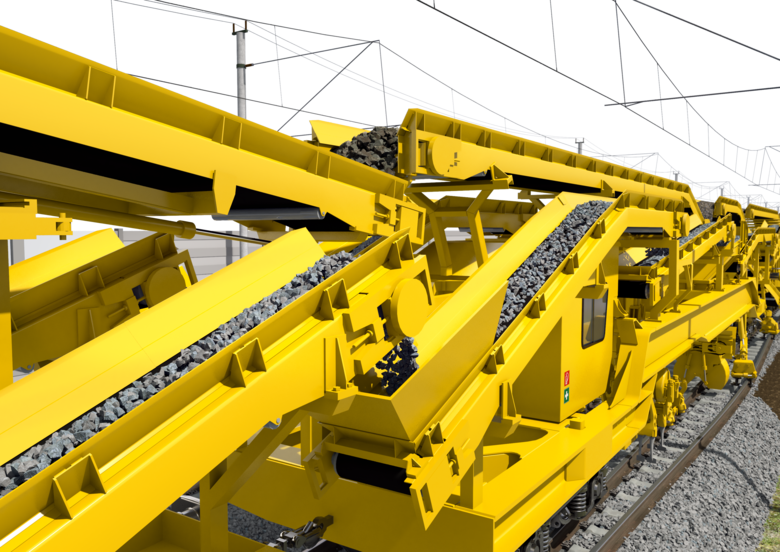

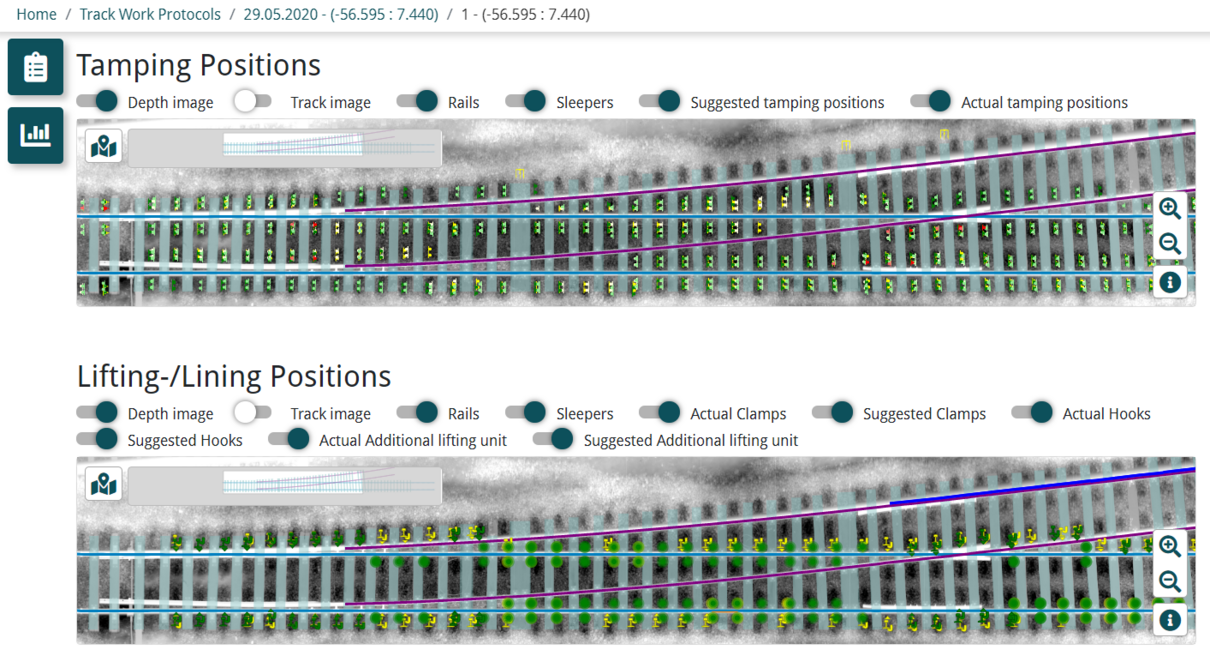

In the field of track construction, sensors and computers are increasingly being used to advance the automation of working processes and optimise track condition recording. Plasser & Theurer is researching possibilities to interlink these systems using Distributed Ledger Technologies. This may help optimise quality assurance at the worksite and will contribute to safe railway operation.

Acceptance reports for increased safety

Before concluding work at a track maintenance site and opening the section for operation, an acceptance report is issued. In order to guarantee safe operation, the track geometry accuracy must be within certain thresholds. Today, reviewing the performed work usually entails printing, checking, and filing the data. While this effort is necessary to satisfy the four-eyes principle, it is also cost-intensive as it requires well-trained staff to be present at the worksites.

This is where Distributed Ledger Technologies can help automate the process. The numerous sensors used at a track construction site communicate in a peer-to-peer cluster (communication between equal computers). They monitor the work units’ working parameters and track quality. Within the cluster, all required parameters are then mutually checked. Using a consensus mechanism, the collected results are cryptographically stored in a block. This is how an ideal track condition is ensured upon opening the track for rail traffic. This block could e.g. serve as a proof of work and trigger an automatic payment to contracting companies. The result? A digital four-eyes principle.

Automated checks and documentation

In the railway field, not only worksites require checks based on the four-eyes principle due to their safety-relevance. Other examples are train construction and approvals, sensor calibration, and the processing of track access charges.

Several areas of application are already emerging that use this relatively young technology to make the railway system more efficient, and, above all, to increase its safety.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/a/9/csm_202109_Visualisierung_beim_Stopfen__1__f0921ecd25.png)