Relevant data for targeted maintenance work:

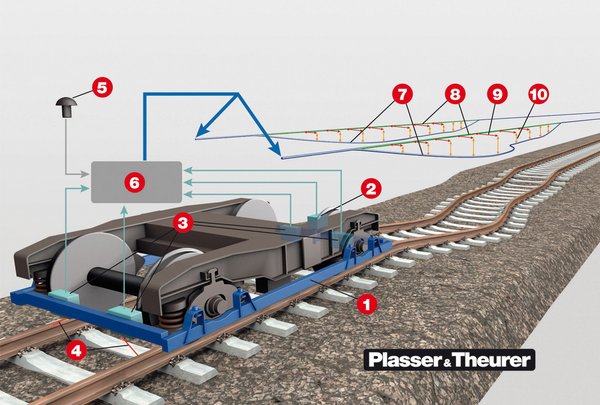

Track geometry recording cars made by Plasser & Theurer supply a wealth of information, depending on their equipment and the requirements. Apart from data on the track geometry, this also includes data on the rail profile, wear of the running edge, rail inclination and surface faults of the rails. Modern measuring systems are capable of measuring the clearance gauge and the ballast profile, monitoring the rail fastenings, video inspection and measuring the position of the contact wire.

Why measure the track?

The track network is a dynamic system. Varying factors such as rail traffic, nature of the subsoil, temperature fluctuations or precipitation are the cause of constant changes. However, to plan maintenance work efficiently, it is necessary to know the current state of the track and above all recognise possible deteriorations.

To obtain the relevant data it is essential to have regular measurements carried out by track recording cars. These scan the entire line network several times a year. The acquired data can be merged in a track geometry data base and are available for long-term analyses. This provides the planning offices with a valuable instrument. Rates of deterioration indicate which type of action would be the most suitable in order to restore the target geometry of the track and to retain it as long as possible.