The EM100VT demonstrates everything that's possible with measuring railway lines nowadays.

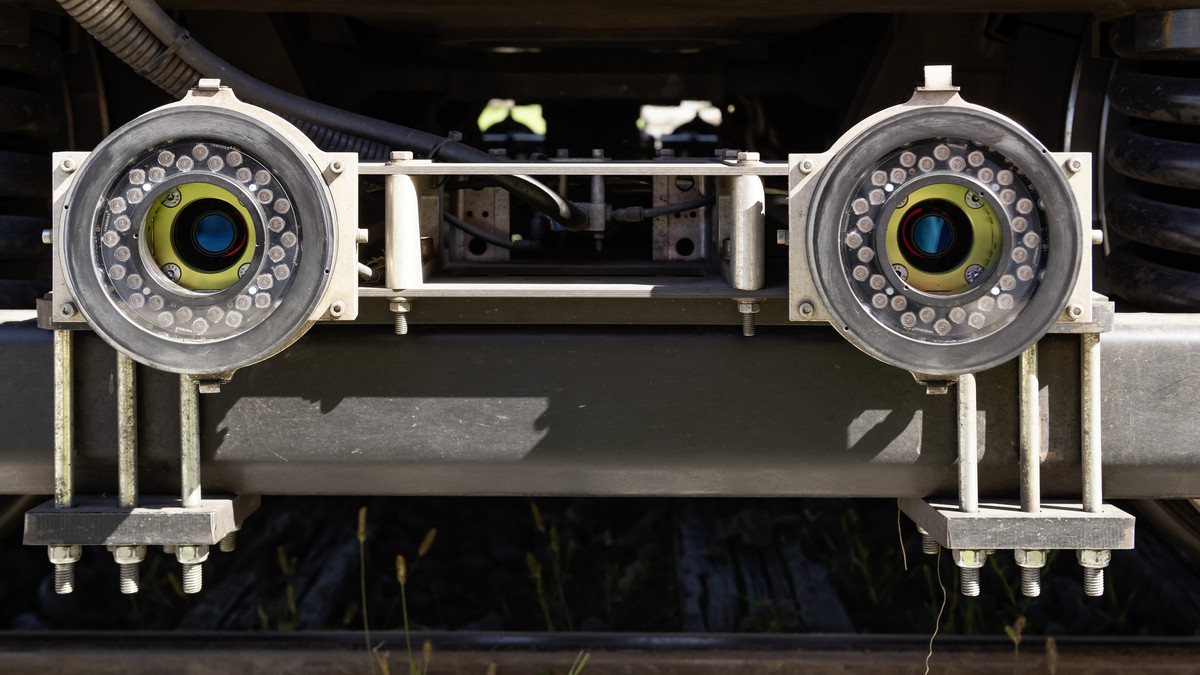

With the EM100VT, the future of capturing infrastructure data on railway track is already reality. Presented for the first time in 2018, the carrier vehicle for new technology features a wide variety of measuring technology and digital options which are sure to impress. On the one hand, the EM100VT is a research platform for technological innovations. On the other hand, it is used in practice for measuring track. The equipment digitally captures the vehicle’s position and many relevant track data in a highly exact manner at speeds up to 100 km/h.