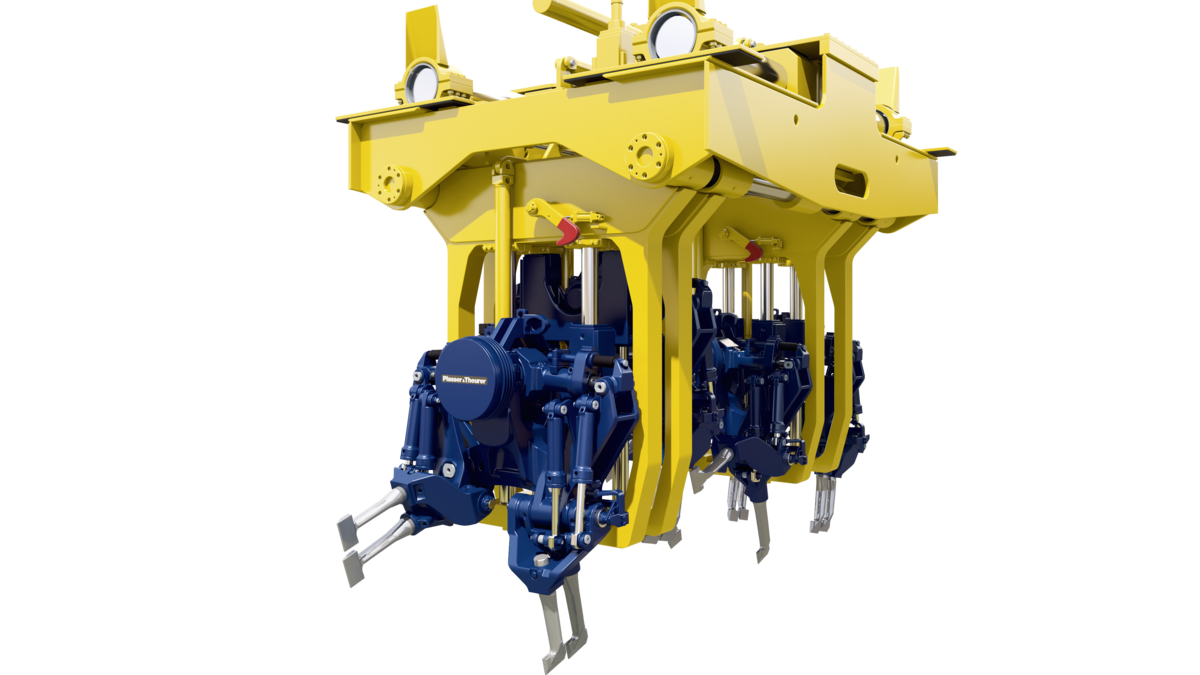

The latest experiences with electrically powered tamping units prove that the future of tamping is electrifying! The economic and environmental benefits of electrification speak for themselves. Plasser & Theurer now offers the eco-retrofit kit, an upgrade from hydraulic work units to electric work units. This way, existing machines can benefit from its advantages.

Advantages of the electrically powered tamping unit

- Less fuel consumption thanks to reduced rotational speed of the drive engine during working mode and reduced power consumption while increasing total efficiency

- Higher efficiency thanks to improved response time of the electric motors

- Lower noise emissions thanks to lower idling speed

- Reduced wear thanks to higher rotational speed during penetration

- Heat development reduction of the entire system thanks to reduced hydraulics

- New opportunity for powering other components electrically (e.g. AC unit, heating system, ventilation unit, and measuring systems such as the Levelling and Alignment Laser/Curve Alignment Laser)

A retrofit for the Buffalo

Plasser & Theurer retrofits are becoming increasingly popular. This comes as no surprise: we as the manufacturer have the perfect prerequisites for performing excellent work. That was also the reason why the SUM-Q3, operated by DB Bahnbau Gruppe, travelled to Linz on 22 December 2021 for a revision that included a retrofit.

The SUM-Q3, dubbed the “Buffalo”, is a track renewal machine that uses the assembly-line method. It’s been part of the Plasser & Theurer portfolio since 1987, and its predecessors have been built since the 1960s. Thanks to integrated ballast management including optional storage of ballast in MFS units (material conveyor and hopper units), the machine concept is still state of the art. That’s what the DB Bahnbau Gruppe operating company and its crew appreciate in the SUM-Q3, even though it’s been in operation for twelve years. The machine has renewed 1,350 km of track to date, primarily on main lines but also on secondary lines. In the past year alone, its output was around 120 km.