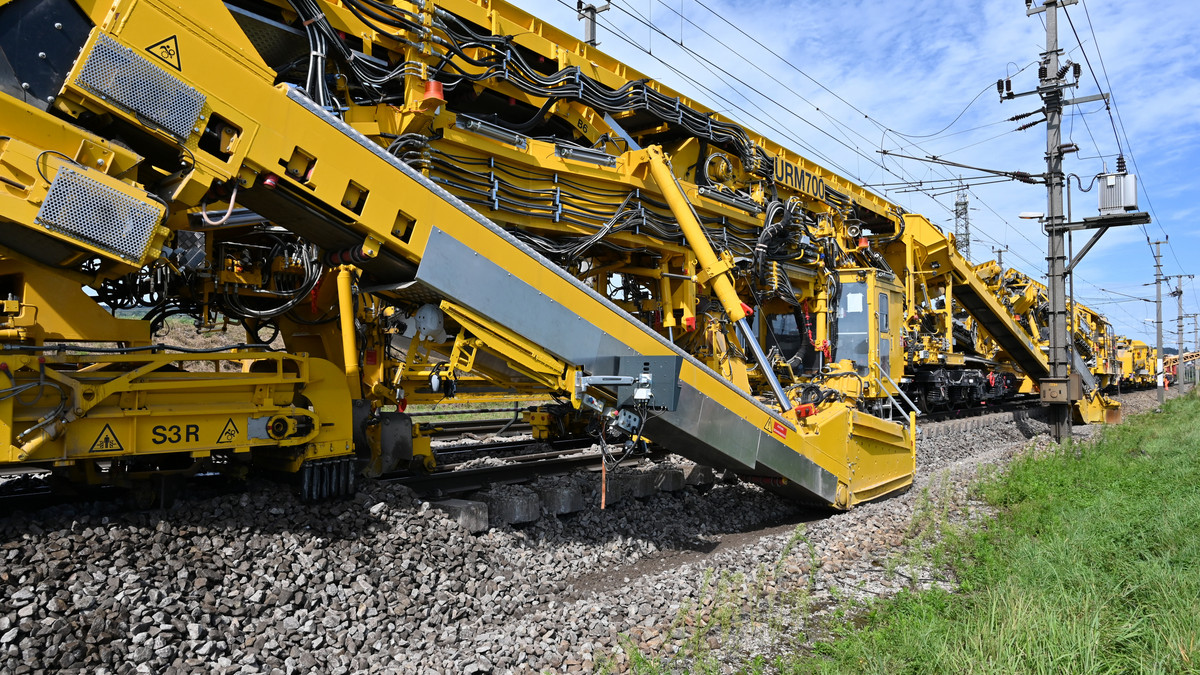

The URM 700-2 universal ballast cleaning machine is our new all-rounder for ballast bed cleaning – it is unique on the world market. The machine offers innovative technology, which we provide as a complete service for turnouts, in a niche segment.

This track-bound turnout-cleaning system is one example of a series of special work and services most conventional contracting company do not offer. We have taken full turnout service to a new level. At Austrian Federal Railways (ÖBB), we have been able to use the technology.

Turnouts place particular demands on maintenance. Due to their key function in the track system, they are considered essential infrastructure components. Turnout installations on modern high-capacity lines consist of concrete sleepers, sensitive drive and control systems, and heavy rail profiles. When maintaining turnouts, these expensive components must be handled with utmost precision.

Cost-efficiency is the goal when handling both turnouts and sections of plain-line track. Strictly speaking, this even more so when maintaining turnouts, as it often affects two tracks at the same time. The duration of track possessions is a key factor, particularly for main lines.

The URM 700-2 offers decisive advantages when managing tight schedules for turnout maintenance. There is no need to remove and reinstall the turnout. Both ballast cleaning and tamping in turnouts can be completed during one single shift. As soon as the work has been completed, the track section can be reopened for traffic.

For this reason, ÖBB have opted for employing our system on their priority routes. During maintenance the adjacent track remains open for traffic, which reduces track possessions to a minimum. This is impossible when employing conventional methods involving excavators and cranes.

Our URM 700-2 ballast cleaning machine is the core technology for turnout maintenance. This machine makes it possible to clean the ballast bed without removing the turnout. Moreover, it allows for continuous working progress. In addition, it cleans the ballast shoulders. The machine is also suited for maintaining large high-speed turnouts with movable-point frog. Another advantage is that sections of track at connecting tracks and between turnouts can be cleaned in one pass.

Thanks to the fast and independent installation and removal of the excavating unit, the URM 700-2 works cost-efficiently on short sections of track.

- Short set-up times

- No need to cut the track, neither at the start nor at the end of work.

- No full track closures - the time required for ballast cleaning in turnouts is reduced significantly.

This is exactly what railway administrations require: fast, safe, and high-quality ballast cleaning in turnouts without long track possessions.