Quality made in Linz

Welcome behind the scenes

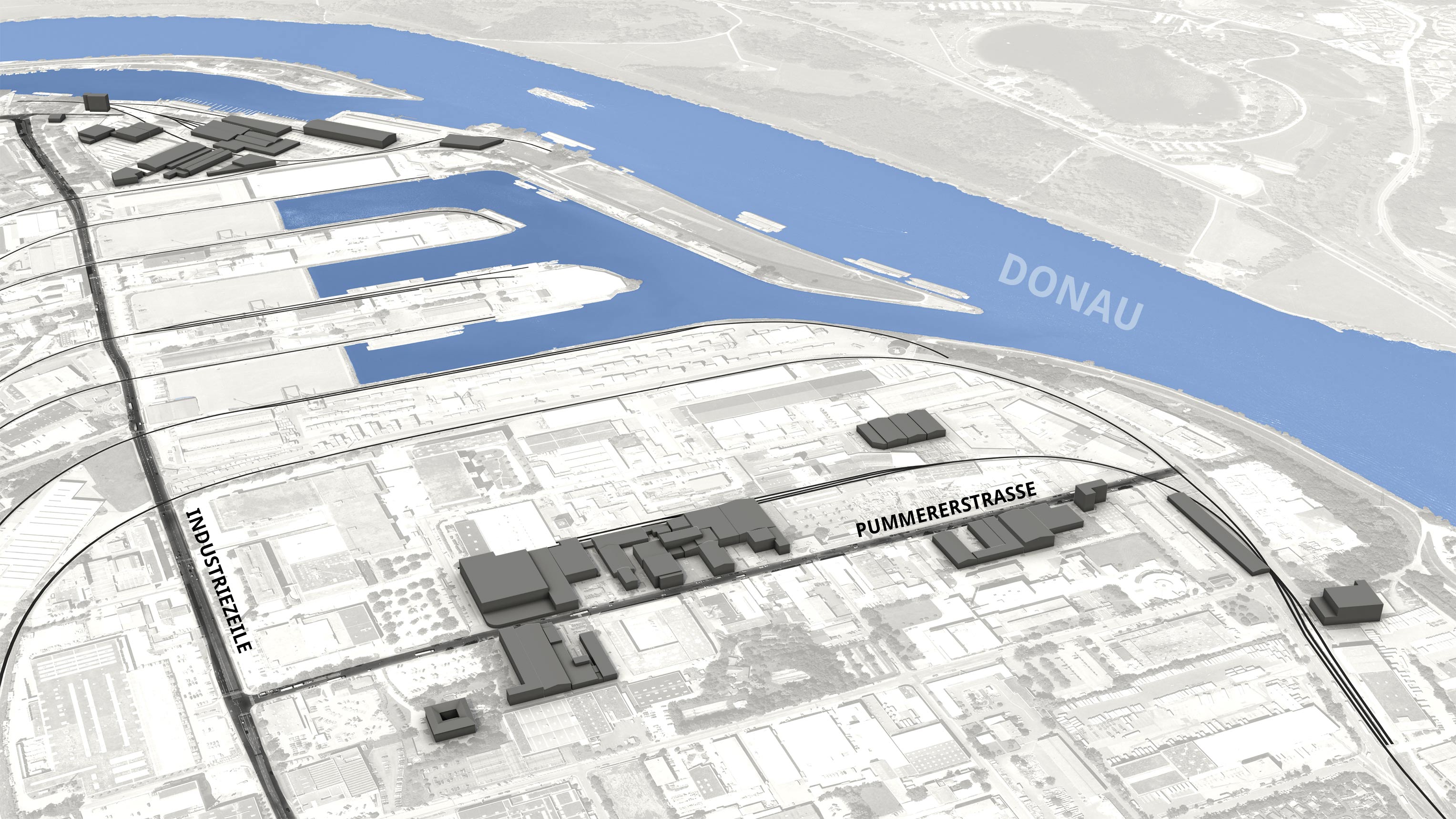

Take a guided tour through our Linz factory here and now. Let the videos guide you through all important areas of the company. You can either click on the desired building in the factory map or choose any of the videos from the list below. Welcome to Plasser & Theurer in Linz!