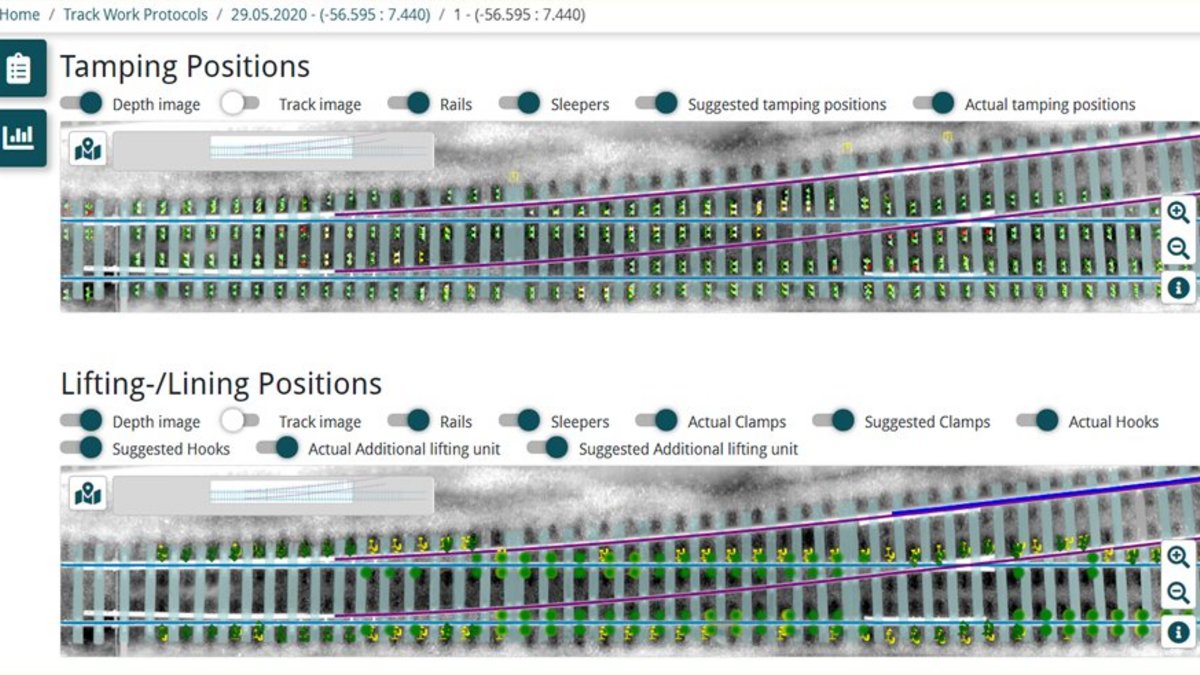

Producing a stable track geometry is in Plasser & Theurer’s DNA. Our machines have performed over 30 billion tamping cycles around the world since 1953. This forms the basis for equipping our machines with the technologies of the future. Plasser SmartTamping is an important evolutionary step towards automated, digitalised track and turnout maintenance. Plasser SmartTamping components integrate seamlessly with one another and can be implemented on the machines either individually or as a fully integrated system.

- Plasser TampingAssistant

is a digital assistant ensuring high tamping quality and process reliability thanks to automated process steps. It also allows less experienced tamping operators to achieve optimum results. - Plasser TampingControl

provides data on the quality of the superstructure and tamping cycle in real time, allowing you to optimise the filling and compaction process. As a result, the track geometry is stable for a long time. - Plasser TampingReport

is a tool for machine operators and infrastructure managers that provides digital documentation of all track maintenance work and transparency in proving work results.