09-32 CSM

2-sleeper tamping machine in 2nd hand condition

| Machine group | Tamping | |

|---|---|---|

| Year of manufacture | 1996 | |

| Track gauge | 1 435 | mm**) |

| CE - Conformity | EU | |

| Length over buffer beam | 27 640 | mm |

| Width | 2 950 | mm |

| Height over top of rail | 3 600 | mm |

| Weight | 69 | t |

| Engine output | 348 | kW |

| Max. travelling speed, self-propelled | 80 | km/h*) |

| Max. travelling speed, towed | 90 | km/h*) |

| Axle spacing in the bogie | 13 700 | mm |

| Distance rear bogie - material trailer axle | 7 500 | mm |

*) Subject to compliance with regulations on use including operation, maintenance, transport, and the relevant approval requirements.

**) Please contact us for any upgrades and retrofits (including other track gauges) as well as optional services.

Subject to technical changes and prior sale.

Machine in articulated design with:

- separate subframe

- two-sleeper tamping units

- ideal tamping frequency of 35 Hz, directional and linear oscillation

- combined lifting and lining unit with two roller lifting clamps and two lining rollers per rail

- sleeper end consolidators on level with the tamping units

- P500 machine control system

- hydrodynamic drive acting on both axles of the front bogie during transfer

- hydrostatic drive on both axles of the front bogie, the subframe axle and the material car axle during working travel

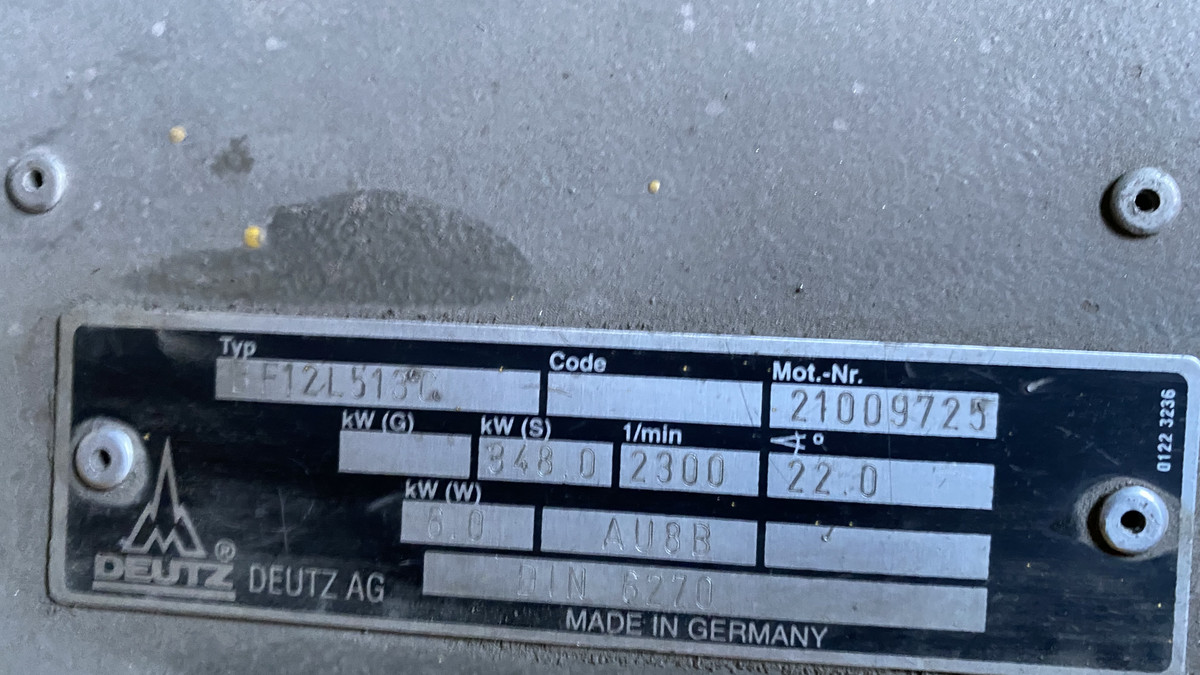

- air-cooled diesel engine type KHD BFl 2L513C

- engine compartment temperature monitoring system

- pneumatically operated block brakes

- indirect braking system with KE valve

- direct braking system

- driver's brake valves

- pneumatic braking during work on the subframe axle

- 2 sound and heat insulated cabins

- ALC - automatic guiding computer

- 6 channel data recorder

- speedometer in each cabin

- air-conditioning in cabin 1

- front windows for transfer travel made of 14 mm safety glass and heated

- intercom system

- integrated material car with extra 1 000 l fuel tank, total fuel tank capacity 2 900 l

- hydraulic oil tank capacity 1 000 l

- panolin hydraulic oil

- lighting and signal according to DB Standard

- track measuring instruments

- safety equipment

- zöllner warning device

- ballast deflector

- buffers and draw hooks

Optional *:

- DRP Data Recording Processor

- Smart ALC

- HRL - Laser System

- prepared for SIFA

- air-conditioning cabin 2

* all upgrades must be checked by the design department