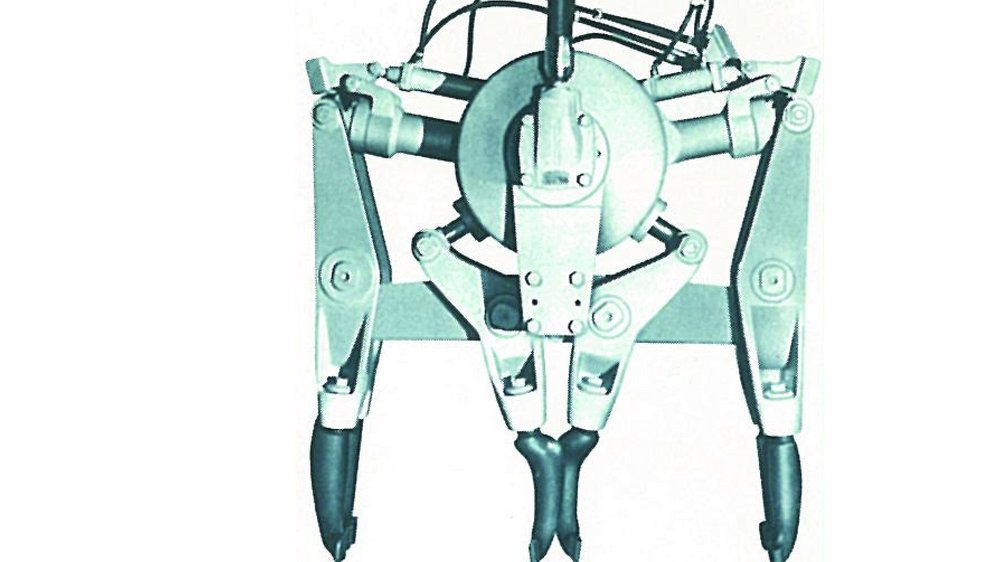

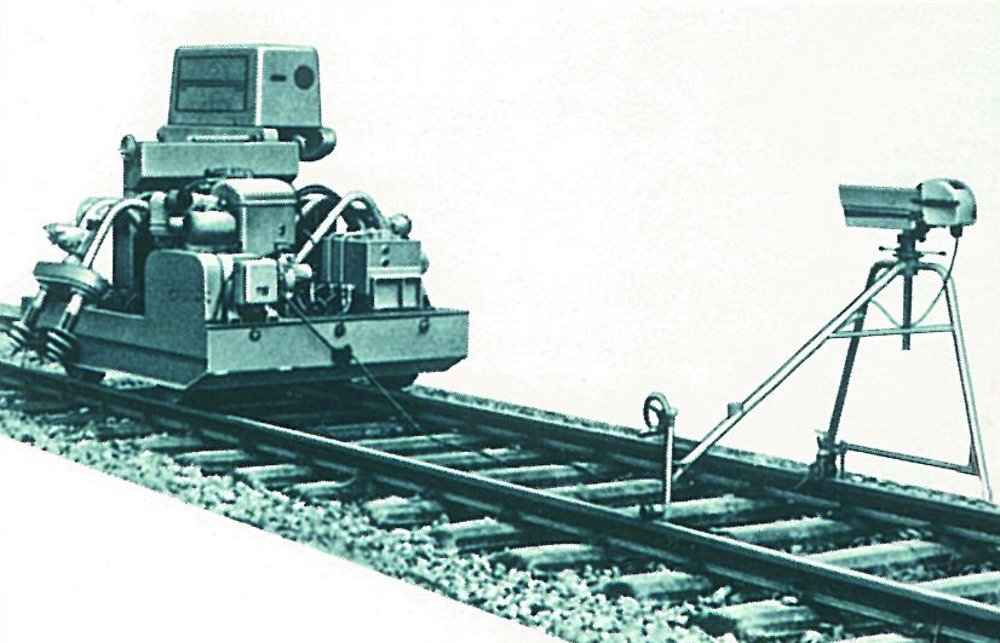

In the early 1950s, there were only tamping machines using mechanical squeezing of the vibrating tamping tines.

The disadvantage was that the ballast was not compacted uniformly.

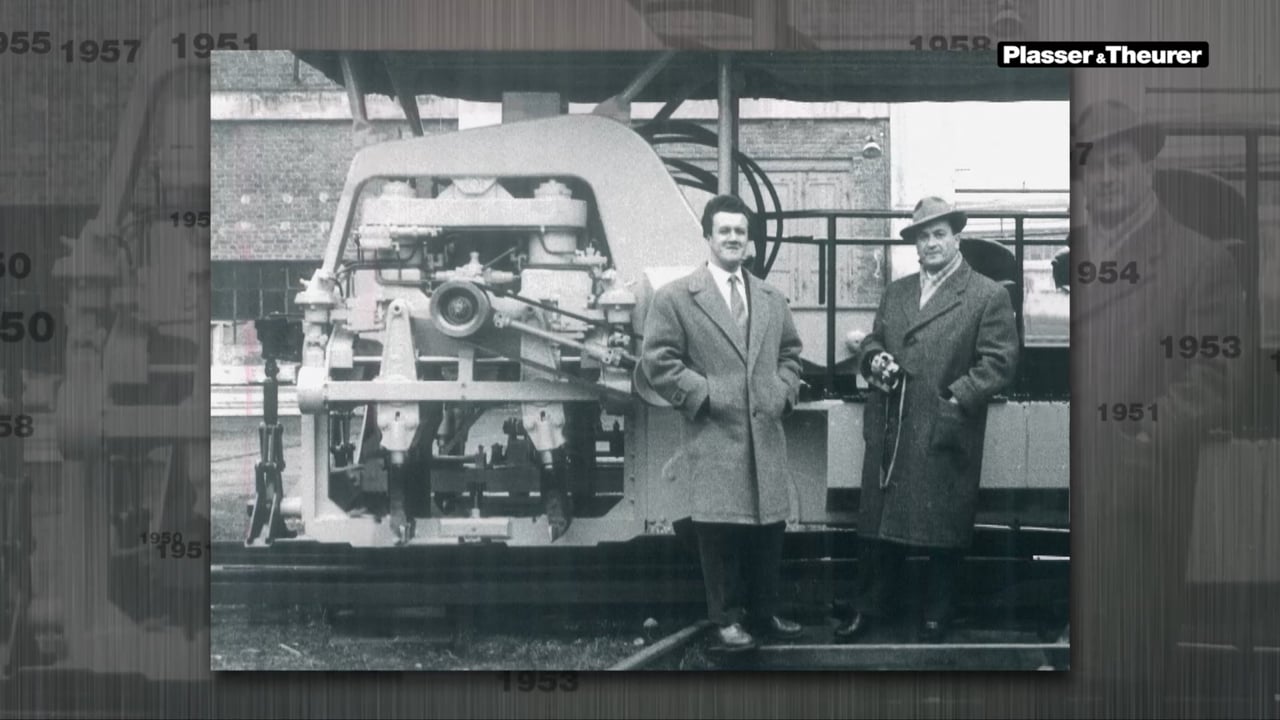

Then I had the idea to introduce hydraulics.Dr. Josef Theurer, founder Plasser & Theurer