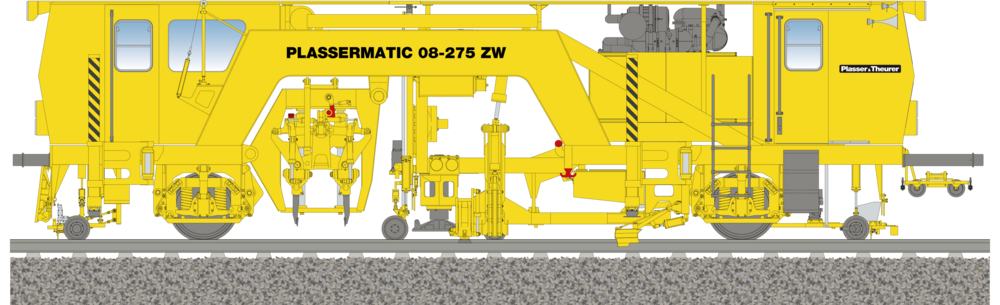

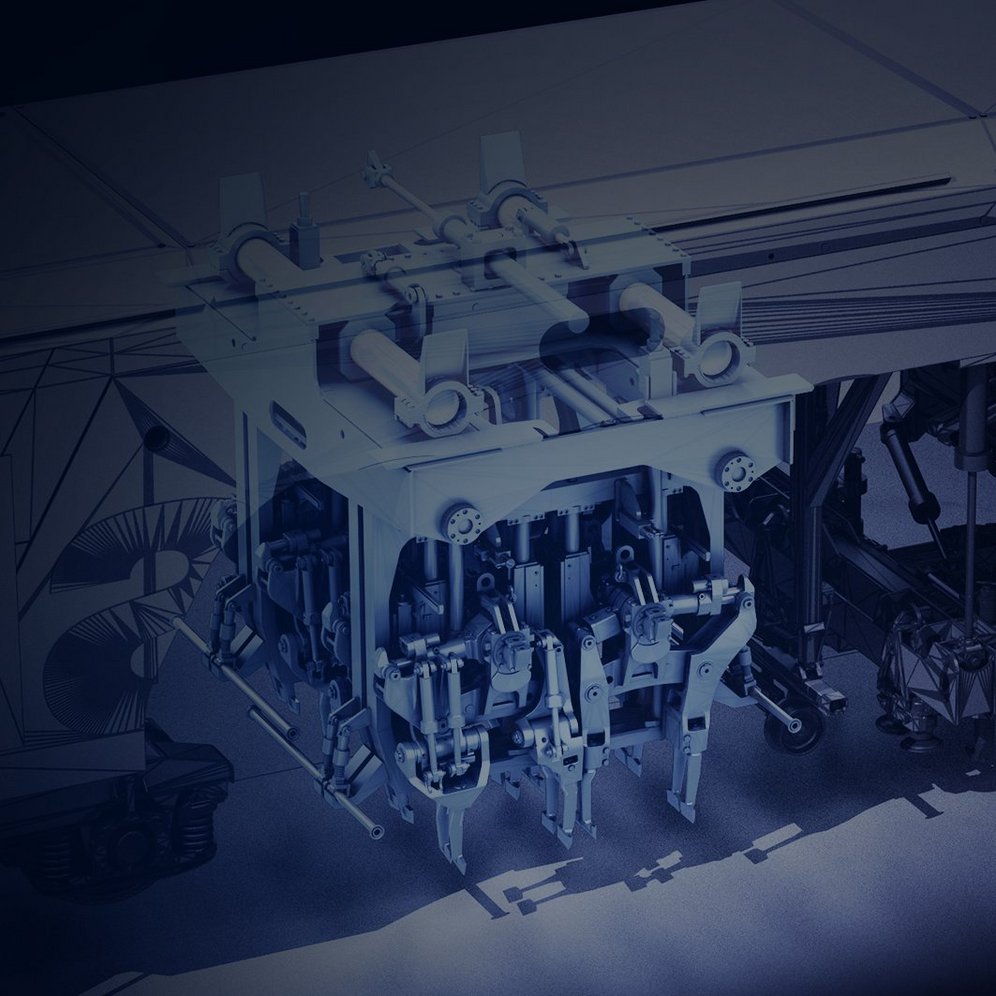

During pressure-vibration tamping, a rotating eccentric shaft generates a vibratory motion of the tamping tines with constant amplitude. As a result, the vibration amplitude is independent of the rigidity of the ballast and meets the requirements of all ballast conditions.

Univ.-Prof. Dipl.-Ing. Dr. Klaus Rießberger