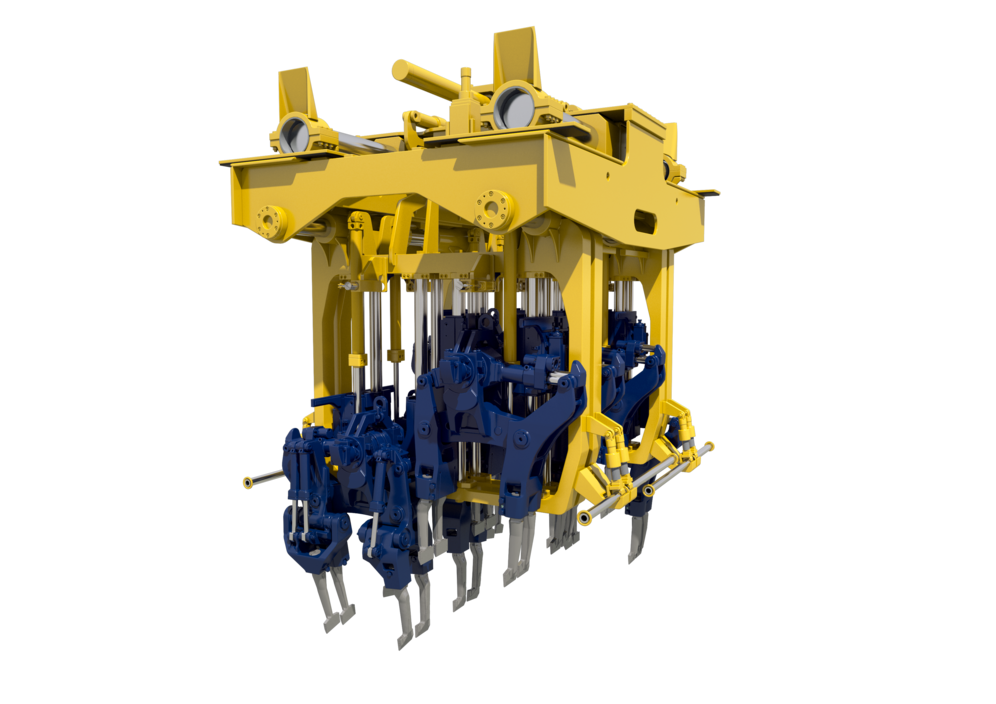

Advantages of multi-sleeper tamping

However, continuously working MULTI-sleeper tamping machines show their full potential not only in short track possessions during maintenance tamping. Machines in the X series also offer advantages when laying new track, for example, following extensive track rehabilitation. They are designed for high lifting and lining forces. As lifts take place in multiple work stages, this also means the machine’s increased output allows you to complete construction noticeably faster.

For quality reasons: MULTI-sleeper tamping units provide more uniform working action, which translates into higher maintenance quality. Owing to a longer frame, bending stress of the rails decreases. And the subframe bogie that fixes it in place prevents elastic rebound of the track after tamping, lining, and lifting.

0

sleepers tamped in a single operation