Plasser Datamatic – MachineConditionObserver

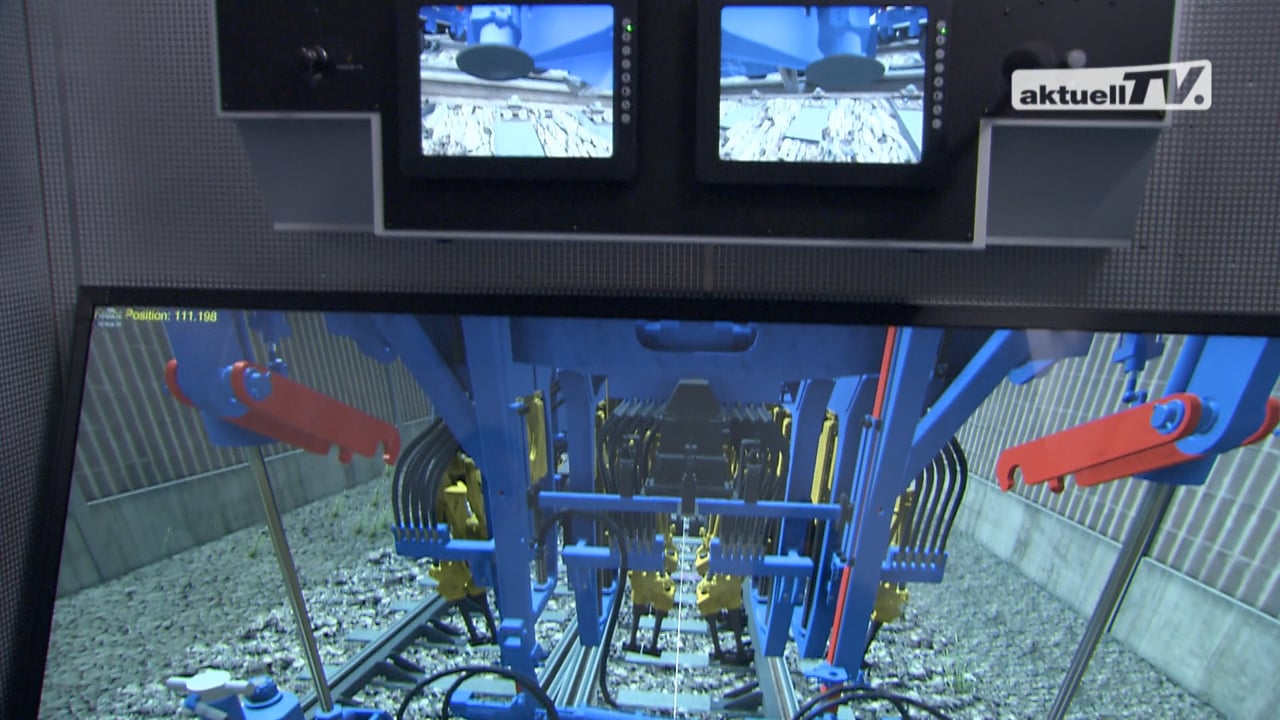

Controlling operation and servicing digitally

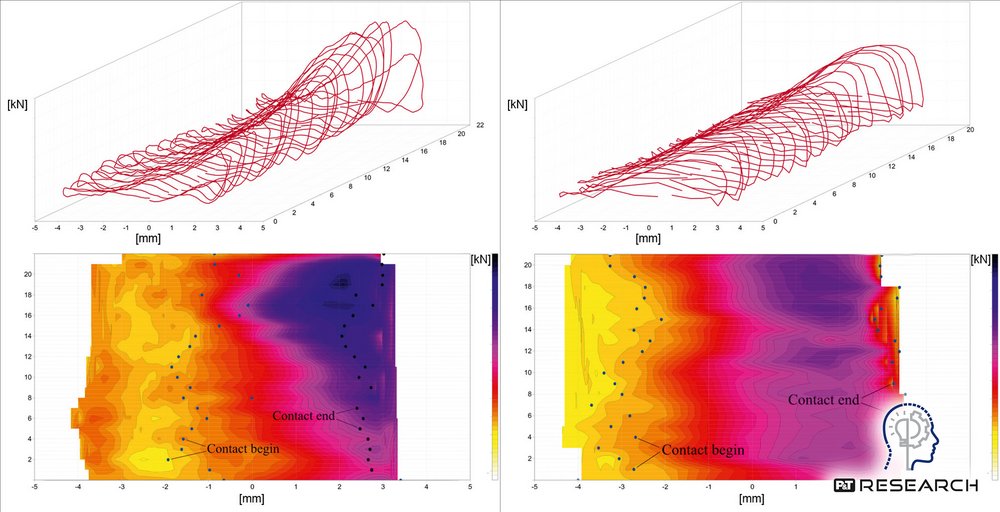

Fleet and maintenance managers can access information on the condition of their machines at any time, allowing for condition-based maintenance and enabling them to plan required measures ahead of time.

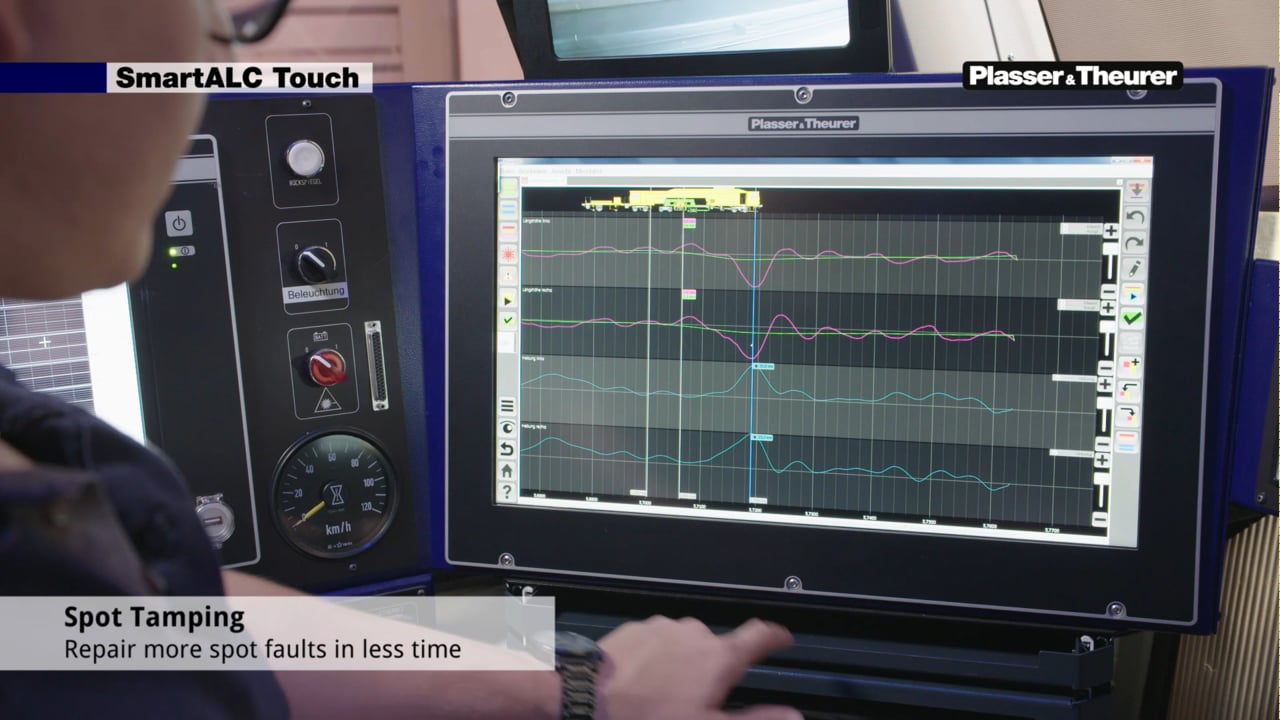

The exact machine position can be accessed at any time, facilitating operations planning and refuelling. The management receives informative reports, providing the basis for strategic decisions.