- Infrastructure

- Urban transport

- Industrial railways

- Field of application

- Turnout

- Track

- Working mode

- Cyclic action

- Spot maintenance

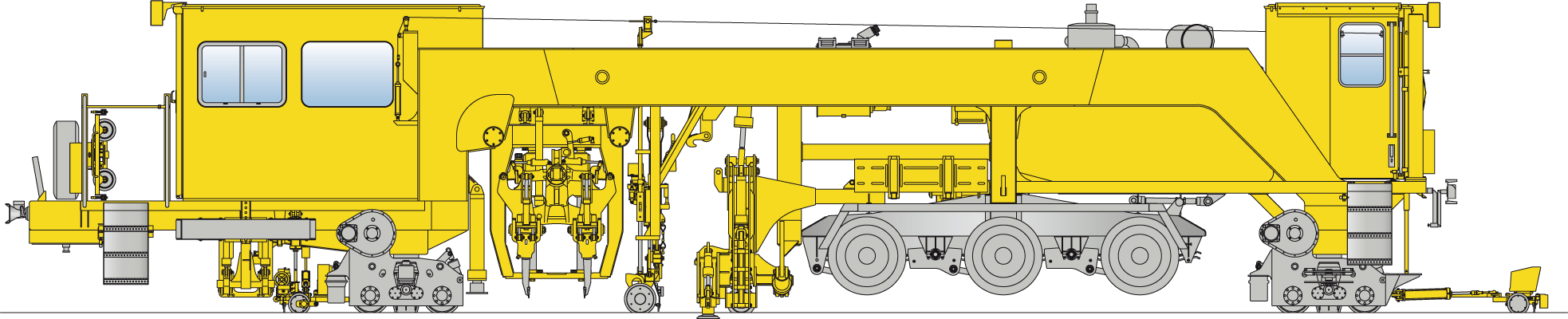

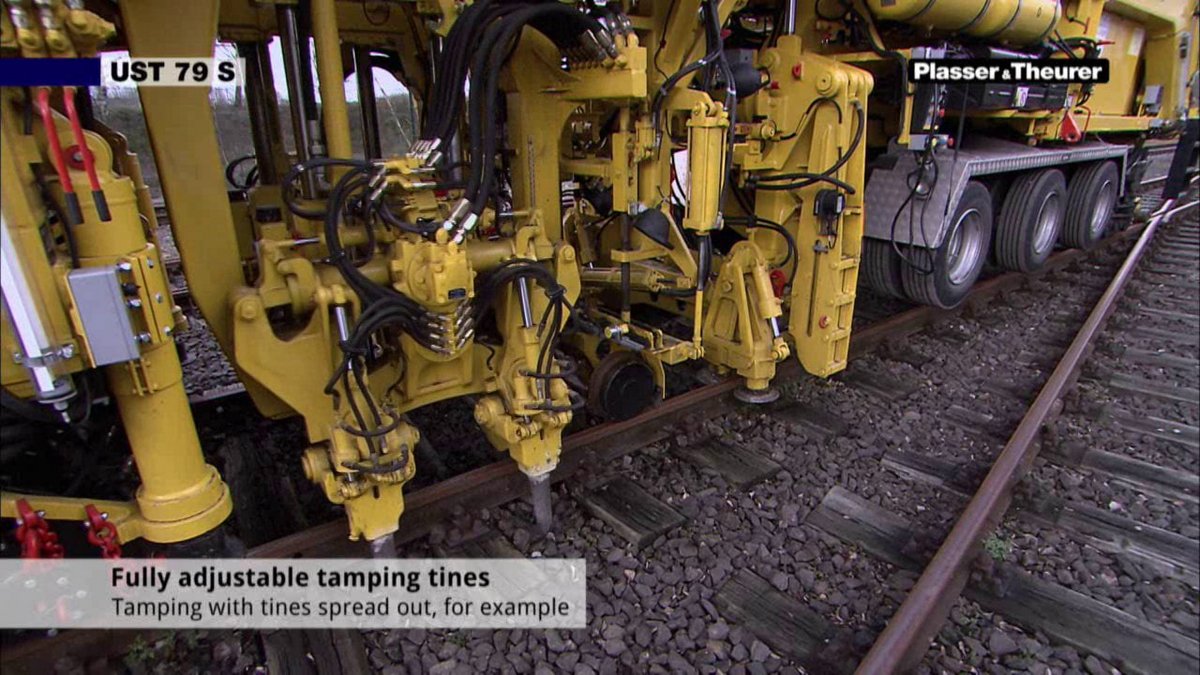

The UST 79 S universal tamping machine is equipped with two bogies for working travel and with a three-axle road chassis and a semitrailer for transport by road.

The result counts

When it comes to tamping the ballast bed, our aim is efficiency and sustainability. Homogenous compaction is not enough. Our aim is to compact the track ballast as much as possible, thereby ensuring a stable track geometry, anticipating settlements, and maintaining the target geometry in the long term. On top of it all, we offer the Dynamic Track Stabiliser: it anticipates initial settlements in a controlled manner, with spatial compaction making the track geometry last longer.

Combined with Dynamic Overlifting, we target the “track’s memory” to prevent faults from reoccurring.

more about Plasser & Theurer tamping technologyFeatures

Individual Design for your individualised machine

When it comes to complex high-capacity machines, the requirements of machine operating companies do vary. Country-specific criteria and individual needs are equally important. We satisfy your special requirements with Individual Design machines. This means we design and manufacture machines tailored to you. In particular, your experiences in daily operation shape the final product.