Highlights

- Flexibility in the turnout and when there are obstacles thanks to tamping unit segments that can be lowered individually

- Fully equipped lifting and lining unit for the turnout – optional additional lifting unit for turnouts – the technology of large Plasser & Theurer machines in compact design

- The compact design also allows for a flexure curve that protects the rails thanks to the distance of 12 m between bogie pivots

- Possible to transport on a lorry between rail networks that are not connected thanks to optional loading mechanism

- Integrate additional maintenance tasks thanks to various trailer options for ploughing, sweeping, stabilizing, transporting, post-measuring, etc.

- More than 100 machines supplied, from narrow gauge to broad gauge – special design for very tight structure gauges (urban areas)

- The global leader in tamping technology – tested under various operating conditions on every continent

- Trust in time-tested technology: newly engineered for operation under the hardest conditions

Technical data

To view the technical data and download a factsheet on this machine, please enter your contact details.

Gallery

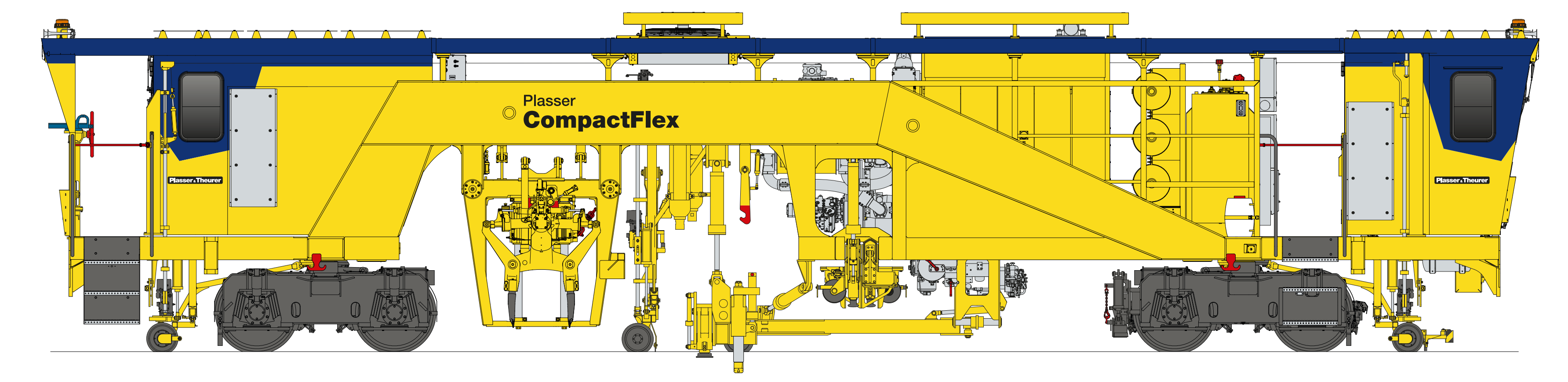

Plasser CompactFlex 1X/SH

Machine illustration

Plasser CompactFlex 1X/SH

zoomInzoomOut

Enjoy the benefits of standardization with ModularCustomizing

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.