- Infrastructure

- Réseau conventionnel

- Charges lourdes

- Grande vitesse

- Réseaux ferrés industriels

- Domaine d‘intervention

- Appareil de voie

- Voie courante

- Tunnel

- Mode travail

- En continu

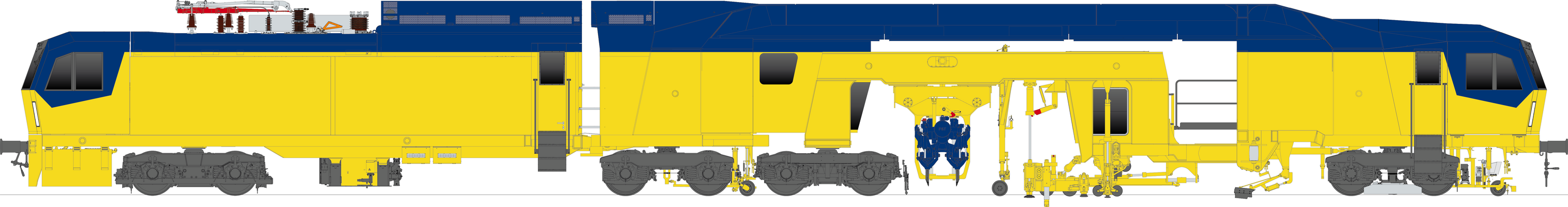

- Hybrid drive concept: uses the overhead contact line or diesel. Can be operated in a carbon neutral way for working and running mode.

- Reduces noise emissions significantly - the machine is ideal for use in urban areas and tunnels

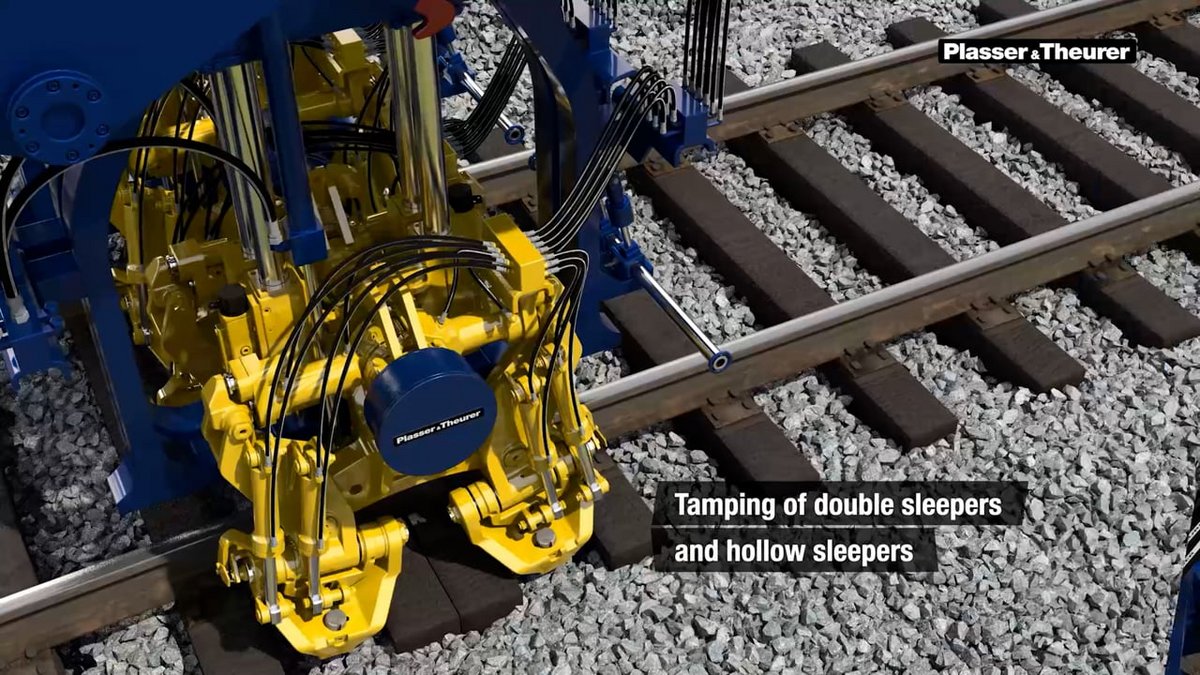

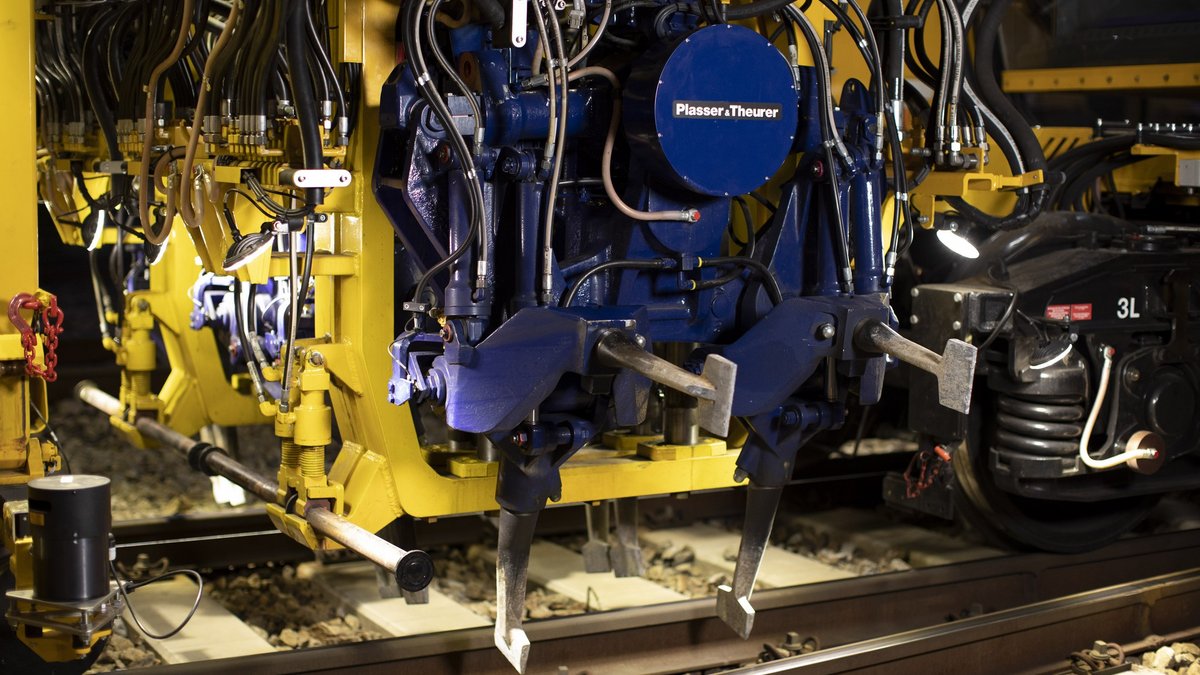

- Variable maintenance of plain line tracks and turnouts

- Maximum flexibility in the turnout thanks to variable use of 16 tamping tines, 3-rail lifting, and 4-rail tamping technology

- The world's leading tamping technology - tested under various operating conditions on every continent

- The frame is designed to maintain the heaviest types of superstructure (heavy haul lines)

- High machine availability thanks to a maximum speed of 100 km/h in running mode under own power

- Approved for line category C2 (axle loads ≤ 20 t)

Fonctionnalités

Individual Design for your individualised machine

When it comes to complex high-capacity machines, the requirements of machine operating companies do vary. Country-specific criteria and individual needs are equally important. We satisfy your special requirements with Individual Design machines. This means we design and manufacture machines tailored to you. In particular, your experiences in daily operation shape the final product.

Economic – Ecologic – Ergonomic

Désormais, les machines de construction de voie utilisent l’énergie électrique de la caténaire ainsi que l’énergie de batteries pour l’entraînement en mode travail. Nos nouvelles technologies d’entraînement E³ réduisent à néant les émissions, en substances nocives et en bruit, sur les chantiers. Depuis 2015, les machines E³ Plasser & Theurer sont synonymes des termes : Économique – Écologique – Ergonomique.