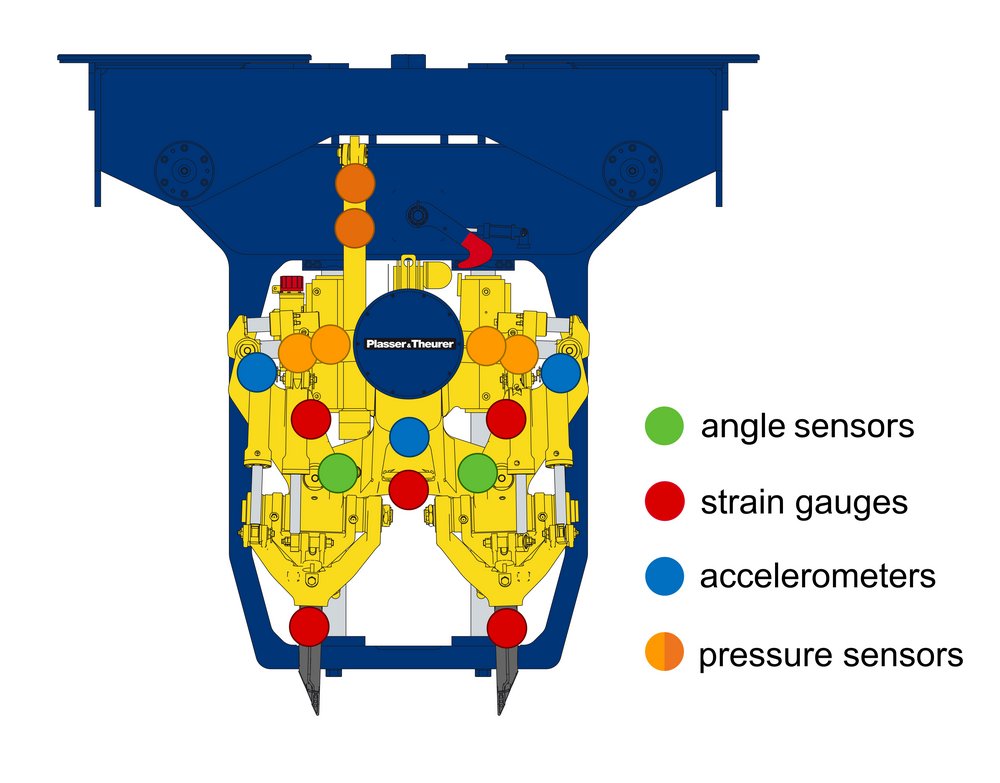

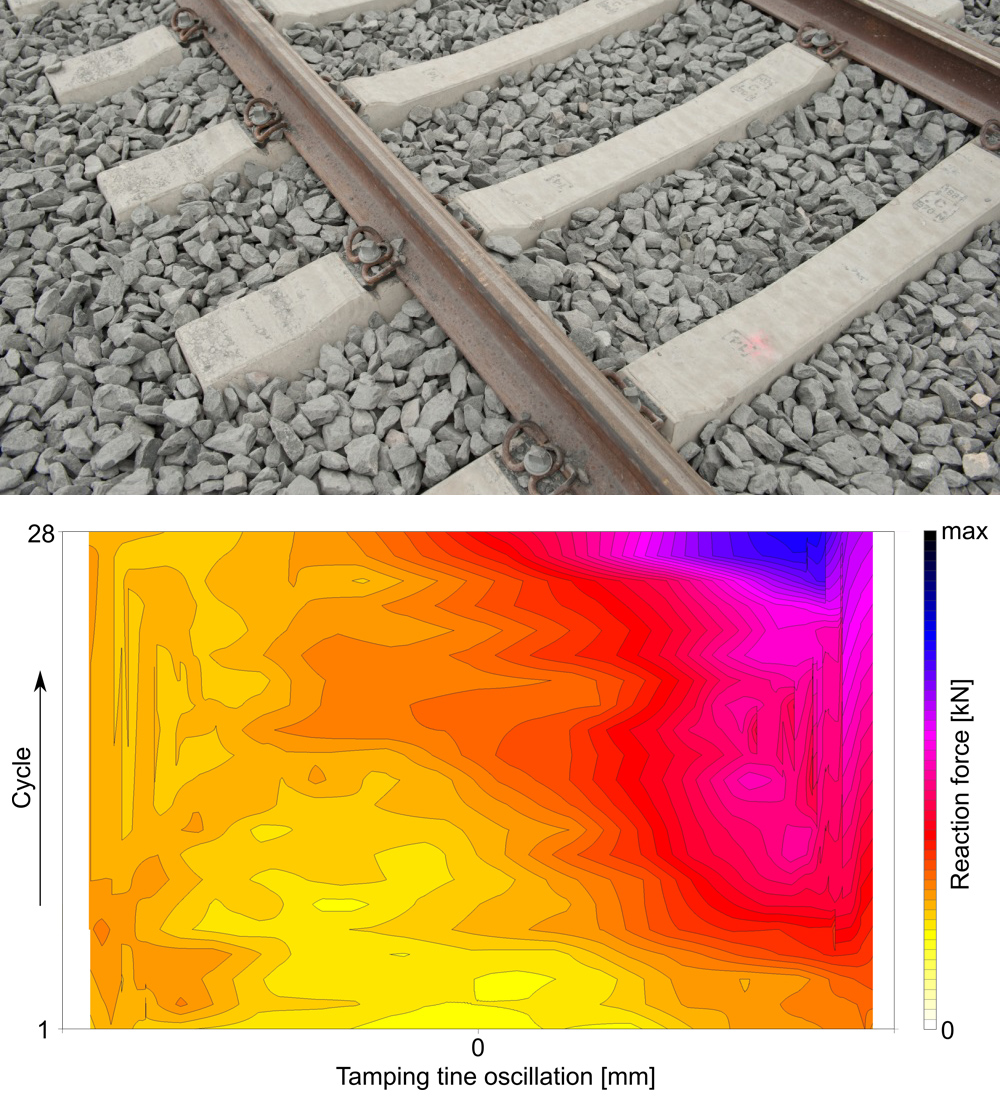

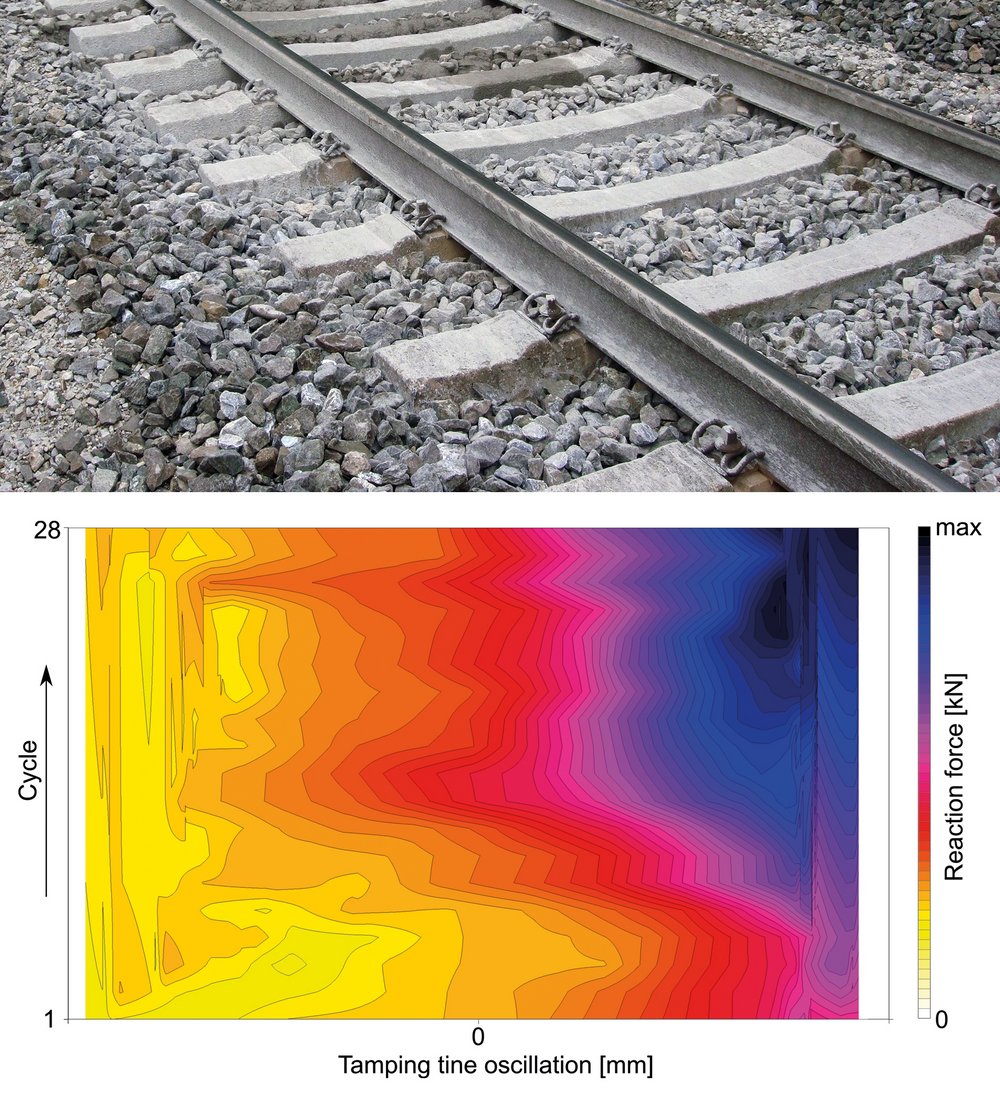

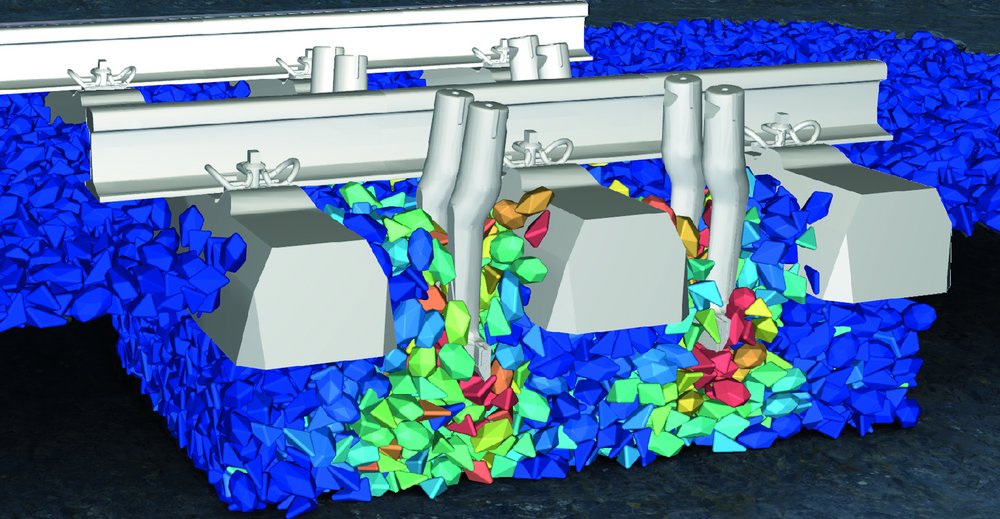

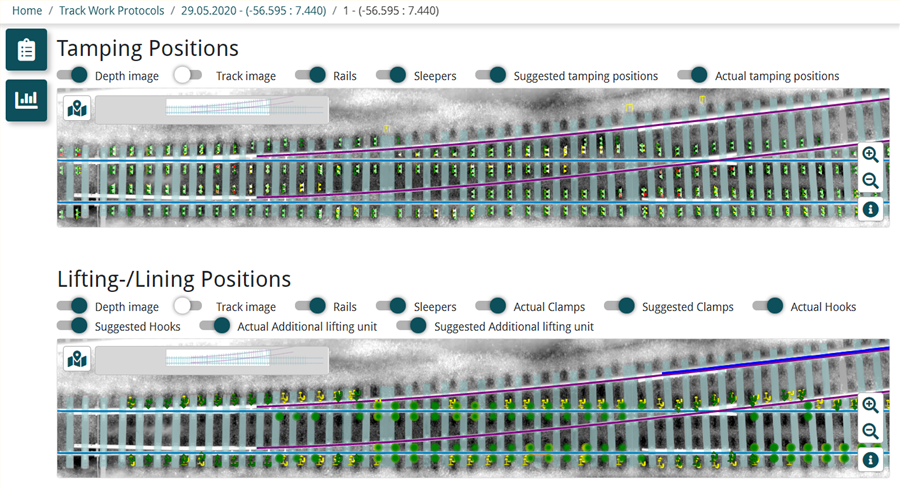

The tamping tine becomes a measuring instrument, and the working parameters are adjusted based on its findings. This makes it possible to improve the quality of the entire infrastructure system while reducing costs.

Priv. Doz. Dipl.-Ing Dr. Fritz Kopf

Univ.-Prof. Dipl.-Ing. Dr. Dietmar Adam, TU Wien