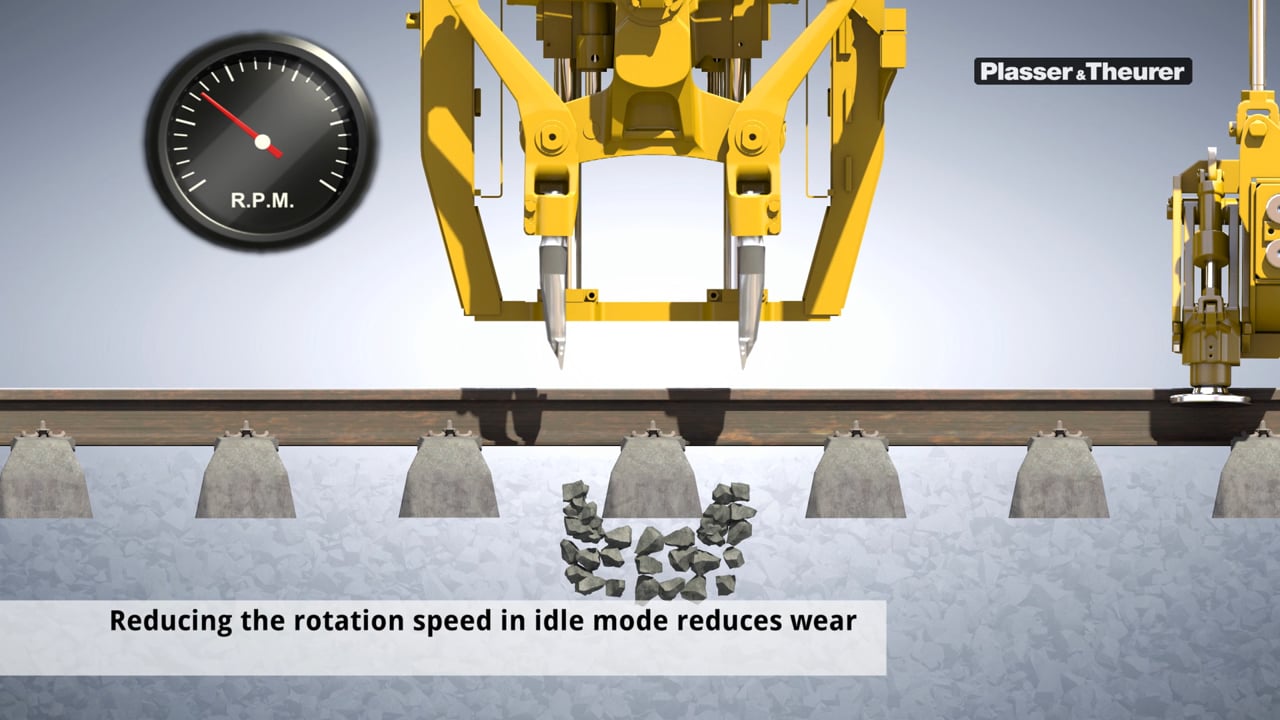

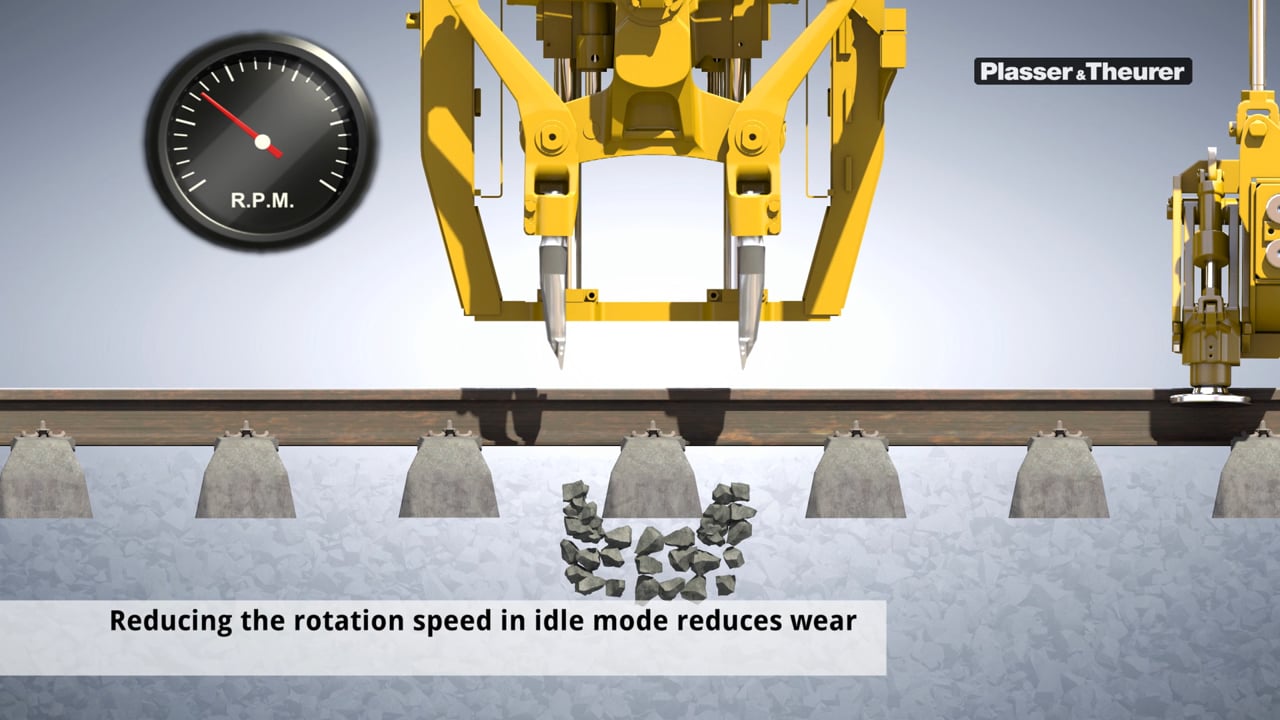

Rotation speed modulation of tamping units

In addition to noise reduction, the rotation speed modulation enables fuel savings of up to 10 %. Moreover, it significantly reduces wear on the tamping units.

0 %

fuel savings

In addition to noise reduction, the rotation speed modulation enables fuel savings of up to 10 %. Moreover, it significantly reduces wear on the tamping units.

On the basis of many years of experience, Plasser & Theurer has developed various lifting and lining units which fulfil both requirements and are well suited for specific operating conditions.

ROLLER LIFTING AND LINING UNIT

This work unit is fitted with two lining rollers and two roller lifting clamps per rail, gripping the rail under the rail head. They lift and line in one operation.

COMBINED LIFTING AND LINING UNIT FOR TURNOUTS AND PLAIN TRACK

This work unit has lifting hooks and lining rollers. On request, it is possible to mount additional roller lifting clamps. Lifting and lining is performed in one operation. The lifting hooks can be applied either under the rail head or under the rail base. The entire work unit can also be displaced in longitudinal direction. This ensures that the work unit can be adapted to every situation during turnout maintenance, achieving an optimum lifting and lining process.

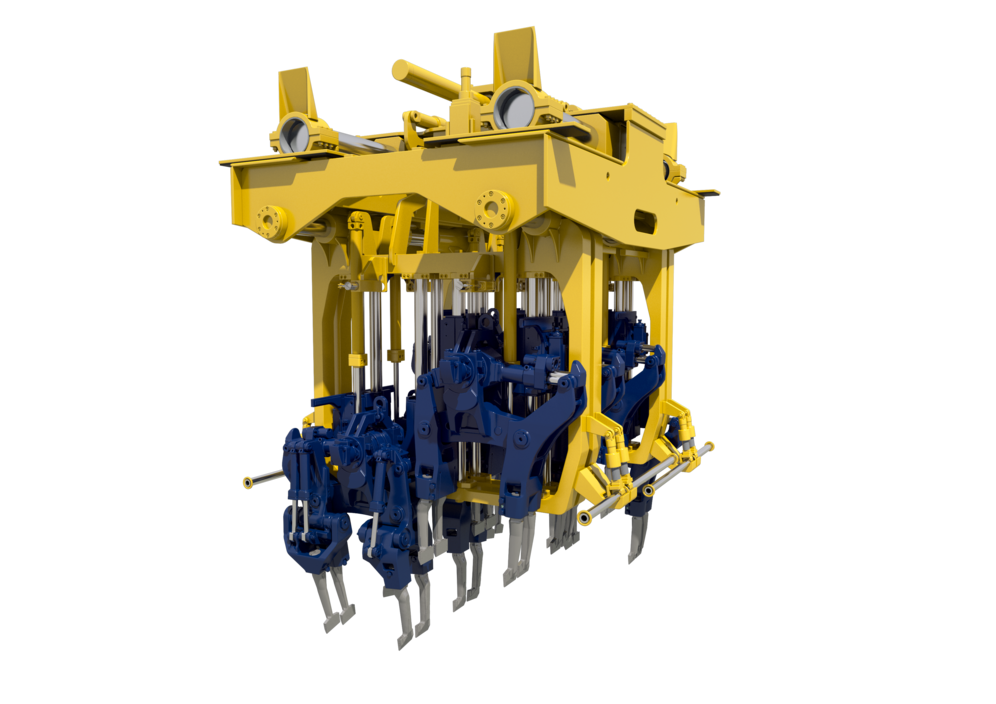

You can choose from a complete range of tamping units for all track and turnout maintenance applications, classified according to output and performance requirements. They are available in various designs and sizes: the perfect fit for all our tamping machines.

High-performance, green lubricants are key to reducing our carbon footprint. Plasser & Theurer paved the way for this approach 22 years ago using organic lubricants manufactured by PANOLIN.

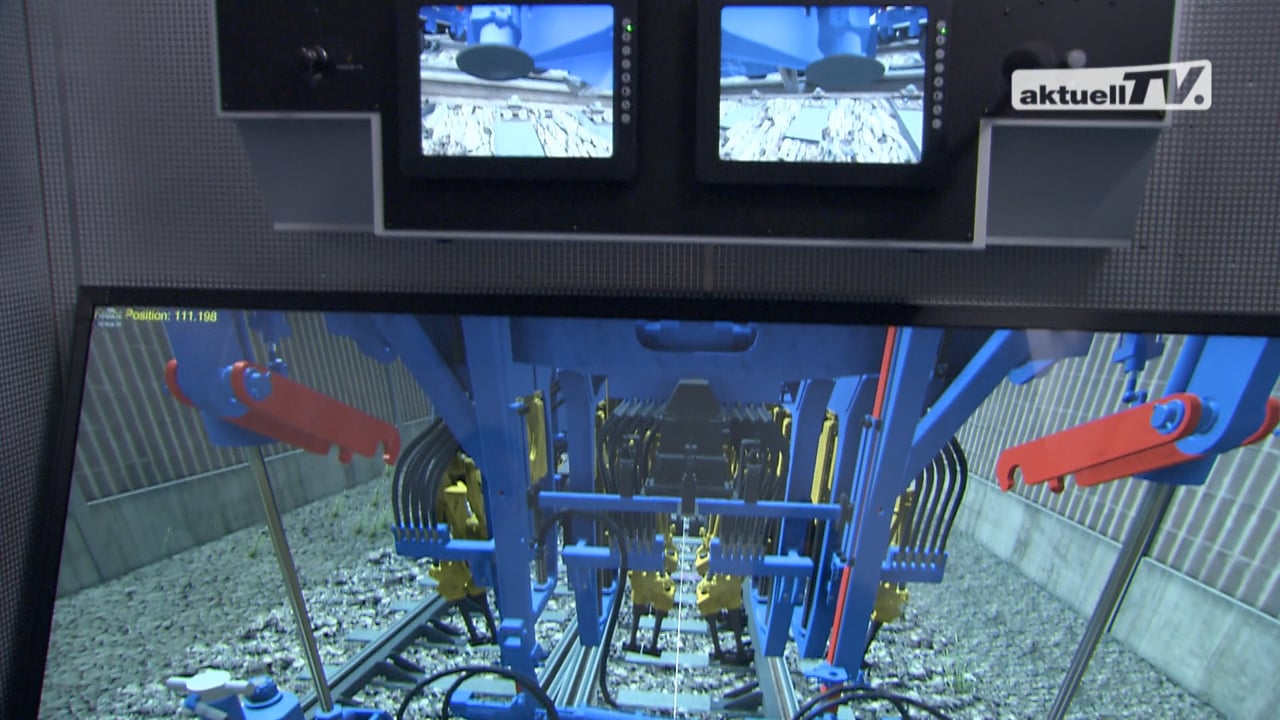

Practical training in a new dimension – the 09-3D tamping simulator

Our tamping simulators demonstrate the convincing advantages of modern simulation technology.

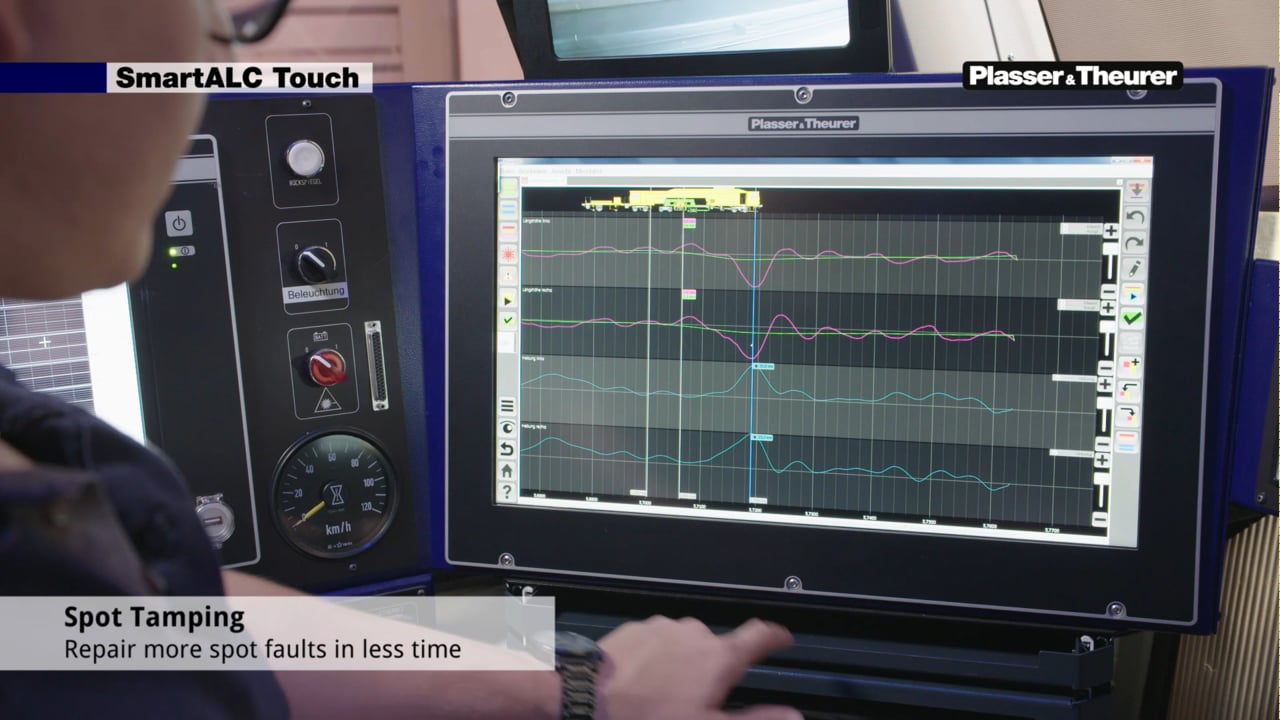

The standard in user-friendliness and process reliability: the track-geometry guiding computer provides ultimate operating comfort. Equipped with the SmartALC, tamping machines can work according to the precision method or the compensation method. Operators can select one of four pre-defined user profiles provided by the SmartALC to ensure their needs are met perfectly. Using AutoSync, for example, the machine automatically detects track defects.