- Infrastructure

- Conventional lines

- Heavy haul

- High speed

- Line with steep gradients

- Field of application

- Track

- Tunnel

- Working mode

- Continuous action

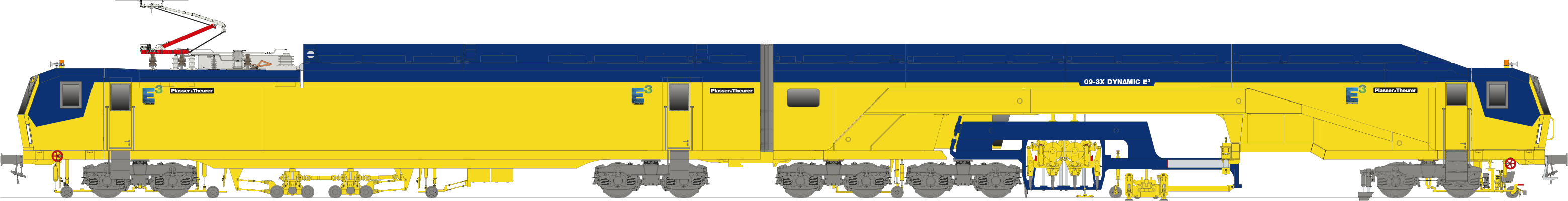

09-3X Dynamic E³

The key component of the 09-3X is the 3-sleeper tamping unit. It allows the machine to tamp three sleepers simultaneously during one single tamping process. Whether it’s maintenance operation or tamping newly laid track: compared to the continuous 2-sleeper tamping machine, the 09-3X model increases output by 30 to 40 %. And that’s not its maximum performance, but rather, an average value.

In 1996, the 3-sleeper tamping technology was introduced for the first time. Ever since, the concept has been used around the world and continues to live up to its reputation. Globally, the name 09-3X is synonymous with simplified worksite logistics, optimal utilisation of track possessions as well as reduced costs for administration and staff.

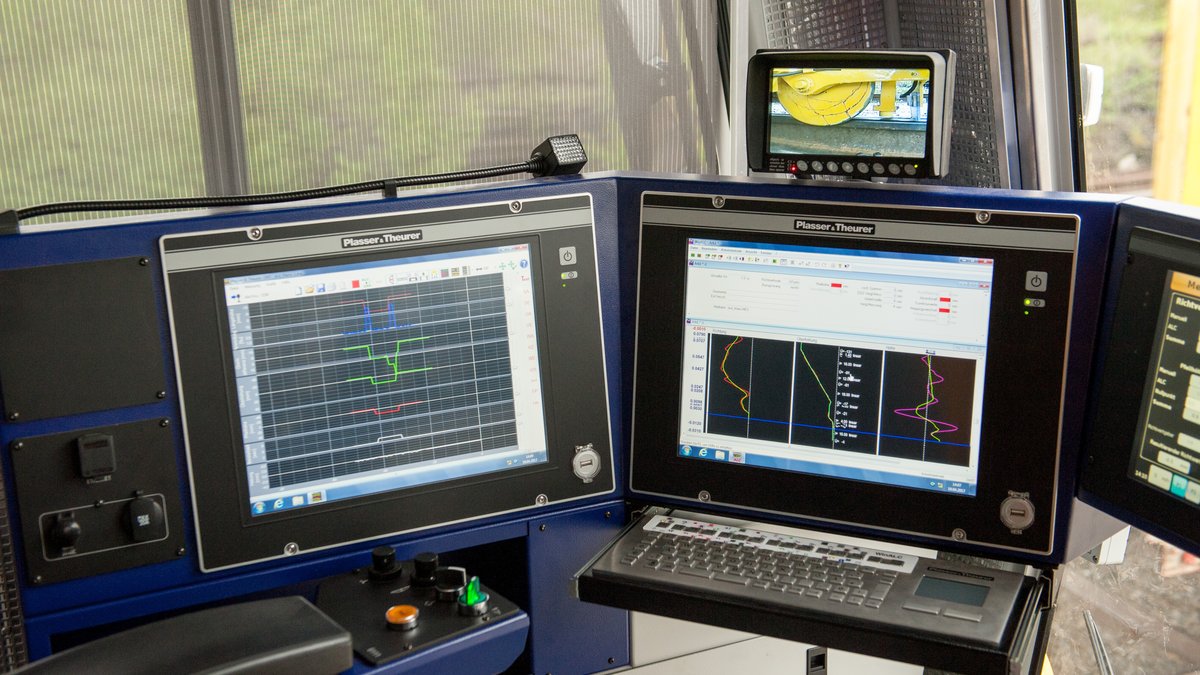

The result counts

When it comes to tamping the ballast bed, our aim is efficiency and sustainability. Homogenous compaction is not enough. Our aim is to compact the track ballast as much as possible, thereby ensuring a stable track geometry, anticipating settlements, and maintaining the target geometry in the long term. On top of it all, we offer the Dynamic Track Stabiliser: it anticipates initial settlements in a controlled manner, with spatial compaction making the track geometry last longer.

Combined with Dynamic Overlifting, we target the “track’s memory” to prevent faults from reoccurring.

more about Plasser & Theurer tamping technologyFeatures

Enjoy the benefits of standardization with ModularCustomizing

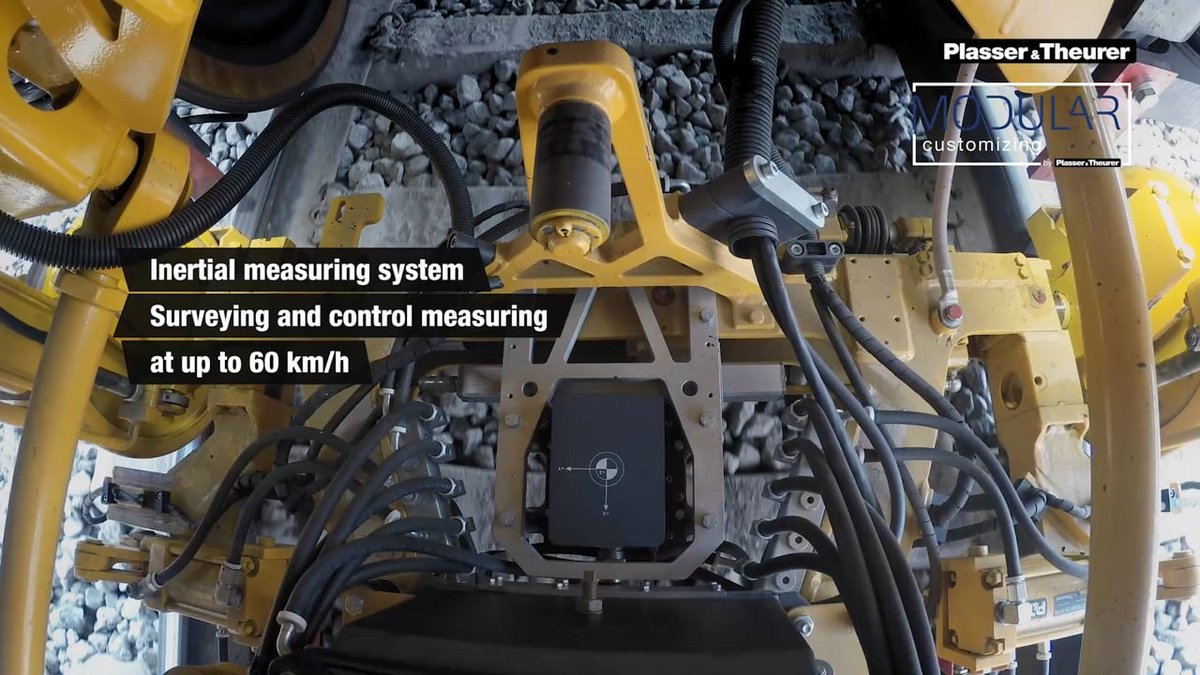

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.

Economic – Ecologic – Ergonomic

The latest track maintenance machines use both the electrical energy from the contact wire and batteries to power the working drive. Our new E³ drive technologies reduce local emissions - of both pollutants and noise – to a minimum on the work site. Introduced in 2015, Plasser & Theurer’s E³ machines stand for: Economic – Ecologic – Ergonomic.