Since 2013, Plasser & Theurer has been offering all services prescribed in the ECM regulation (Entity in Charge of Maintenance). In addition to the manufacturer's technical know-how, we also have valuable experience in implementation. Our ECM services will give you the legal certainty required, and you can simply outsource all the associated work. In addition to the specific services, we also engage in developing digital tools for implementing the ECM standard.

Our services

- ECM management function

- ECM maintenance development

- ECM fleet management

- ECM maintenance delivery

- Certified as a railway undertaking with Safety Certificates Part A and B

- Development of an ECM maintenance guideline as the basis for servicing, maintenance, and repairs

Your benefit

- Legal certainty for your vehicle fleet

- No additional work for keeping track of current regulations

- Quality assurance thanks to manufacturer know-how

- Use of original spare and wear parts

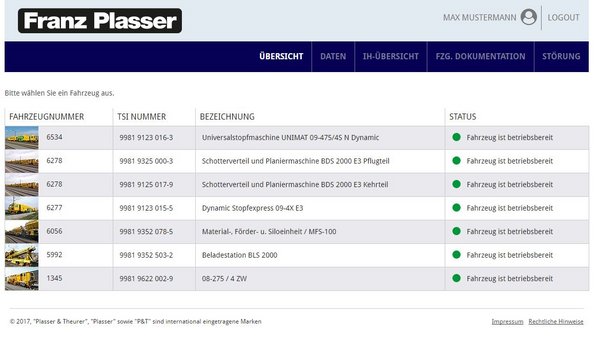

- Overview of everything thanks to the online documentation system

- PlasserFleetControl with data on machine status and maintenance history as well as advance information on upcoming servicing activities

Legal certainty also for operators of track maintenance machines

In recent years, legal certainty has been gaining importance for operators of rail vehicles. The introduction of the EU regulation 445/2011 has been governing the maintenance of freight wagons. It must be performed by an Entity in Charge of Maintenance (ECM) according to a strictly defined set of rules since 2011.

Certified according to the ECM standard since 2013

The EU regulation 445/2011 has been a particular concern of ours right from the beginning. In July 2013, Franz Plasser Dienstleistungsgesellschaft mbH (DLG) based in Purkersdorf obtained the ECM certificate for all four main functions of the EU regulation. At the same time, the Purkersdorf maintenance workshop was awarded with the ECM certificate for the maintenance delivery function. Since then, we have performed maintenance according to the ECM standard.

In mid-2016, DLG also obtained the Safety Certificate Part A and Part B as a railway undertaking. This has enabled us to take aspects of railway operation into account for maintenance.

In addition, we now offer the web-based platform PlasserFleetControl. As a part of PlasserSmartMaintenanceSuite, it gives access to the entire maintenance history, the current maintenance status and other information that can be defined individually - at a push of a button. Protocols and documents make the progress achieved during maintenance transparent at any time. The integrated fleet management shows the next servicing and maintenance dates, facilitating the planning of machine operation. At the same time, malfunctions can be inputted, triggering our service technicians to react promptly.

Based on PlasserFleetControl, we also meet the requirements of the ECM certificate on documentation and record keeping for the operation and maintenance of your machine.

ECM maintenance guideline in the making

A maintenance guideline (IHLF) contains all required maintenance and servicing steps to be carried out over the entire service life of the machines. In addition, it suggests measuring and testing methods with regard to standards and regulations.

Together with renowned experts, we have developed the first IHLF according to ECM criteria tailored for special vehicles and track maintenance machines. Its structure makes it possible to take full account of national particularities, infrastructure features, and customers' requirements. It will soon be available as an electronic tool.

EUROPTEN: highly satisfied with maintenance according to ECM standard carried out by Plasser & Theurer since 2013

EUROPTEN (European Trans Energy GmbH) is one of the major players in overhead line construction in Europe. With around 140 technicians, it carries out projects in Germany, Switzerland and Austria. Plasser & Theurer machines are used for many of the works performed. At the Purkersdorf location, fifteen machines and ten freight wagons have been maintained according to the ECM standard since 2013. Markus Straka, Head of Overhead Line Projects, EUROPTEN, shares his experiences with us:

Why does your company place importance on maintenance according to ECM standard?

Straka: The safety authorities increasingly delegate responsibility to the contractors. Therefore, legal certainty is important for us to be protected in case problems occur.

Why did you select Plasser & Theurer for the maintenance of your machines?

Straka: When the EU regulation 445/2011 was published, we realised that it would involve too much effort to have EUROPTEN certified according to the ECM criteria. To ensure the legal certainty required, we had to find a partner who could maintain our machines according to the ECM standard. We have known Plasser & Theurer for many years as manufacturer of our machines and maintenance service provider.

Has it been the right decision?

Straka: Absolutely. I would even say that Plasser & Theurer is the perfect partner for this task as the company has the manufacturer's expertise and knows the machines better than anybody else. It produces spare parts in-house. Therefore, the timely supply is always ensured. This is also true for old or rarely needed parts. At the Purkersdorf location, Plasser & Theurer has the infrastructure and the staff required to perform maintenance works according to ECM standard.

Has maintenance changed since the introduction of ECM?

Straka: Yes. Its quality has clearly increased. The documentation has improved significantly. All processes have become more transparent for us as a customer. Traceability has definitely increased.

What is the greatest advantage in outsourcing maintenance?

Straka: There was no need for us to obtain the ECM certificate. In addition, we appreciate that maintenance is taken care of for us. If we had to maintain the machines in-house, it would be necessary to always stay up-to-date on laws and technical developments. Plasser & Theurer is taking care of this on our behalf so that we can fully focus on our core business.

Thank you for your time.

On-topic: maintenance according to EU regulation 445/2011

On 29th June 2009, a freight train derailed in Viareggio, Italy. Loaded with butane, its wagons exploded in the station area. Thirty-two people lost their lives. The surrounding infrastructure was heavily damaged. This tragedy was caused by a broken wheel set shaft at the first wagon.

To prevent such accidents from happening again in Europe, the EU adopted a regulation for the servicing of freight wagons. On 10th May 2011, the EU regulation 445/2011 came into force.

It stipulates uniform standards for the certification of maintenance workshops for freight wagons in all EU member states. The Entity in Charge of Maintenance (ECM) has a system of maintenance that meets stipulated requirements and ensures the safe operating condition of the maintained freight wagons.

The four main functions of the ECM certification

1 Management function

This supervises and coordinates the maintenance functions and ensures the safe state of the freight wagons. It also comprises general management tasks according to ISO 9001 (e.g. risk management and competence management). The management function is the only function the ECM cannot transfer to other companies.

2 Maintenance development function

Besides the management of the maintenance documentation (document management) during the entire service life of the machine, it describes the state of the vehicle technology and documents the vehicle's history. This function ensures that the respective competence and documentation requirements are met.

3 Fleet maintenance management function

It manages the freight wagons or parts of the freight wagons' removal for maintenance and their return to operation after maintenance. It comprises:

- commissioning

- periodic inspection/revision

- repairs

- conversions

- usage restrictions

- putting the machine back in service

4 Maintenance delivery function

This function defines the required technical maintenance of a freight wagon including the release to service documentation. In detail, it describes

- audit of contracts

- management of resources

- workplace evaluation

- final testing and release to service

- proof/traceability of the works performed

- testing and measuring equipment monitoring